Nanofiber-hydrophobic starch compound-based filtrate reducer for drilling fluid and preparation method thereof

A technology of nanofiber and fluid loss control agent, which is applied in the field of drilling fluid products, can solve problems such as poor temperature resistance, achieve the effect of improving temperature resistance, easy promotion, and improving fluid loss control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

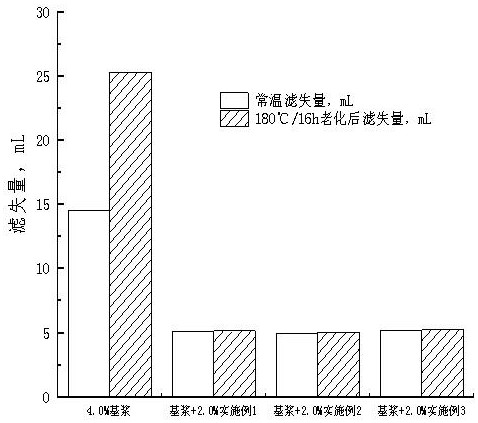

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The specific preparation method of the present invention comprises the following steps:

[0035] 1. Pretreatment of bagasse

[0036] (1) Clean the bagasse with deionized water, dry it, and press it with a press for several times in a row. After squeezing out all the sugar, clean it with deionized water, put it in an oven, and heat it at 80℃± Dry at 5°C for 5 hours and take it out;

[0037] (2) Pulverize the dried bagasse with a pulverizer, test with a standard inspection sieve, pulverize to 800 mesh to 1000 mesh, and set aside.

[0038] Among them, the bagasse used is the residue after the sugar cane is squeezed. The sugar cane is mainly produced in subtropical regions such as Guangxi and Guangdong. The main components are vitamins, fat, protein organic acids, calcium, iron and other substances.

[0039] 2. Preparation of Cationic Nanofiber Suspension

[0040] (1) Pour 500~700g of 98% sulfuric acid into a 2000mL three-neck round-bottomed flask, slowly add deionized w...

Embodiment 1

[0057]Pour 500g of 98% sulfuric acid into a 2000mL three-necked round-bottomed flask, slowly add deionized water, stir while adding dropwise (speed 300rpm), adjust the temperature to 45°C until the sulfuric acid is diluted to 64wt%; Put the processed bagasse in a 2000mL flat-bottomed flask, slowly add the prepared 64wt% sulfuric acid dropwise, and stir at a low speed of 300rpm for 50min. , to obtain a milky white suspension; transfer the previous system to a dark place, add 120g of sodium periodate, react for 3h under dark conditions, then add 6mL of ethylene glycol, stir at 1000rpm, continue to react for 1h, remove unreacted high Sodium iodate; increase the temperature of the reactor to 60°C, adjust the pH to 4.0~5.0, add 20g of cetyltrimethylammonium bromide, and continue the reaction for 1h; transfer the above dispersion system into a 5000mL large plastic cup , add excess deionized water to terminate the reaction; transfer the above dispersion system to a centrifuge in batc...

Embodiment 2

[0059] Pour 700g of 98% sulfuric acid into a 2000mL three-necked round-bottomed flask, slowly add deionized water, stir while adding dropwise (speed 300rpm), adjust the temperature to 45°C until the sulfuric acid is diluted to 64wt%; Put the processed bagasse in a 2000mL flat-bottomed flask, slowly add the prepared 64wt% sulfuric acid dropwise, and stir at a low speed of 300rpm for 50min. , to obtain a milky white suspension; transfer the previous system to a dark place, add 130g of sodium periodate, and react for 4h under dark conditions, then add 6mL of ethylene glycol, stir at a speed of 1000rpm, continue to react for 1.5h, and remove unreacted Sodium periodate; increase the temperature of the reactor to 60°C, adjust the pH to 4.0~5.0, add 25g of dodecyltrimethylammonium bromide, and continue the reaction for 1.5h; transfer the above dispersion system to 5000mL large plastic In the cup, add excess deionized water to terminate the reaction; transfer the above dispersion syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com