Electrochemical preparation method of porous graphene dispersion liquid

A technology of porous graphene and dispersion liquid, applied in chemical instruments and methods, graphene, inorganic chemistry, etc., can solve the problems of complex operation process, high equipment requirements, long time consumption, etc., and achieves low preparation cost, low equipment requirements, good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

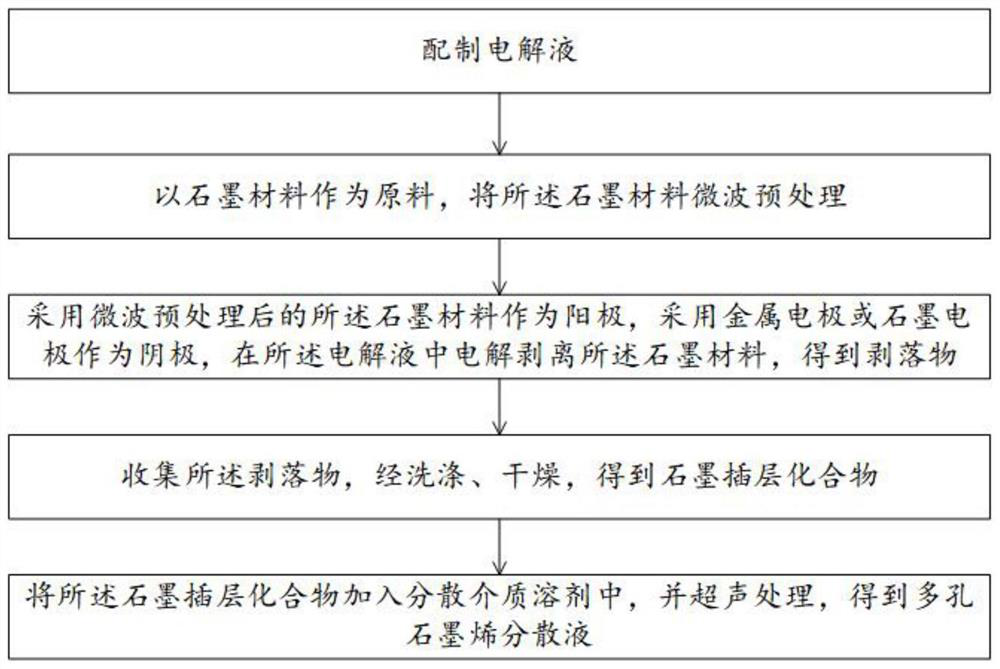

[0043] The present invention provides a kind of electrochemical preparation method of porous graphene dispersion liquid, refer to figure 1 , including the following steps:

[0044] S1, preparation of electrolyte;

[0045] S2. Using graphite material as a raw material, pretreating the graphite material with microwaves;

[0046] S3. Using the graphite material after microwave pretreatment as an anode, using a metal electrode or a graphite electrode as a cathode, electrolytically stripping the graphite material in the electrolyte to obtain exfoliation;

[0047] S4, collecting the exfoliation, washing and drying to obtain a graphite intercalation compound;

[0048] S5. Add the graphite intercalation compound into the dispersion medium solvent, and perform ultrasonic treatment to obtain a porous graphene dispersion.

[0049] The principle of the electrochemical preparation method of porous graphene dispersion liquid of the present invention is: because microwave pretreatment for...

Embodiment 1

[0053] The present embodiment provides a kind of electrochemical preparation method of porous graphene dispersion liquid, comprises the following steps:

[0054] S1, prepare 0.1mol / L ammonium sulfate+0.5mol ammonia aqueous solution as electrolyte;

[0055] S2. Using an electrode formed of natural graphite as a raw material, pretreat the graphite electrode with microwave, the microwave power is 3000W, and the microwave time is 5min;

[0056] S3. Use the pretreated graphite electrode as the anode, and the metal platinum electrode as the cathode. Place the two electrodes vertically with a parallel distance of 2 cm. Control the temperature of the electrolyte in the constant temperature electrolytic cell to 35°C, and use a constant current of 0.5A to electrolytically peel off the graphite. electrodes, get exfoliation;

[0057] S4, collecting the exfoliation in step S3, washing and drying the exfoliation, drying and dehydrating in a constant temperature drying oven to obtain a grap...

Embodiment 2

[0061] The present embodiment provides a kind of electrochemical preparation method of porous graphene dispersion liquid, comprises the following steps:

[0062] S1, prepare 0.1mol / L ammonium sulfate aqueous solution as electrolyte;

[0063] S2. Using the electrode formed by synthetic graphite as raw material, pretreat the graphite electrode with microwave, the microwave power is 500W, and the microwave time is 10min;

[0064] S3. Use the pretreated graphite electrode as the anode, and the metal gold electrode as the cathode. The two electrodes are placed vertically with a parallel distance of 2 cm. The temperature of the electrolyte is controlled at 35°C in a constant temperature electrolytic cell, and a constant current of 0.5A is used for electrolytic stripping. Graphite electrode, get exfoliation;

[0065] S4, collecting the exfoliation in step S4, washing and drying the exfoliation, drying and dehydrating in a constant temperature drying oven to obtain a graphite interca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com