AGV task scheduling method based on simulated annealing algorithm

A simulated annealing algorithm and task scheduling technology, which is used in computing, complex mathematical operations, data processing applications, etc., and can solve problems such as short completion time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

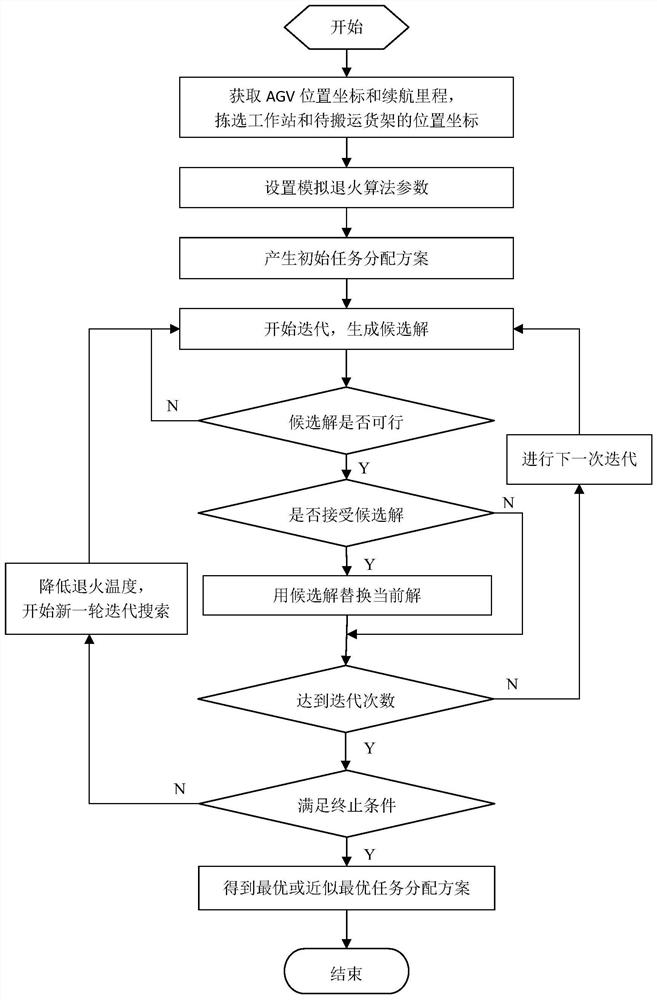

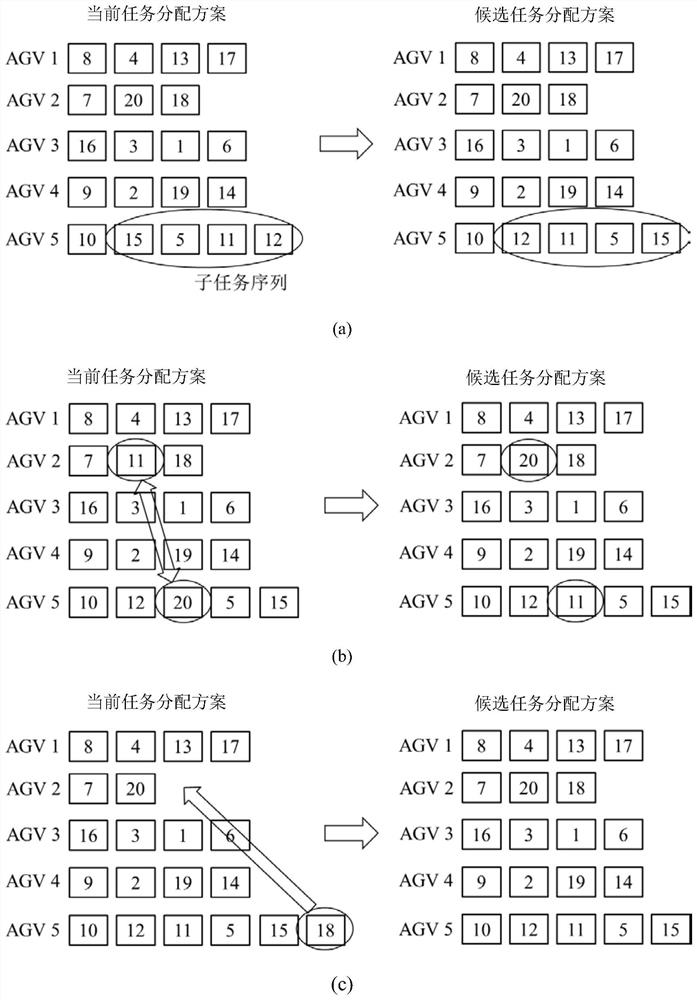

Method used

Image

Examples

Embodiment

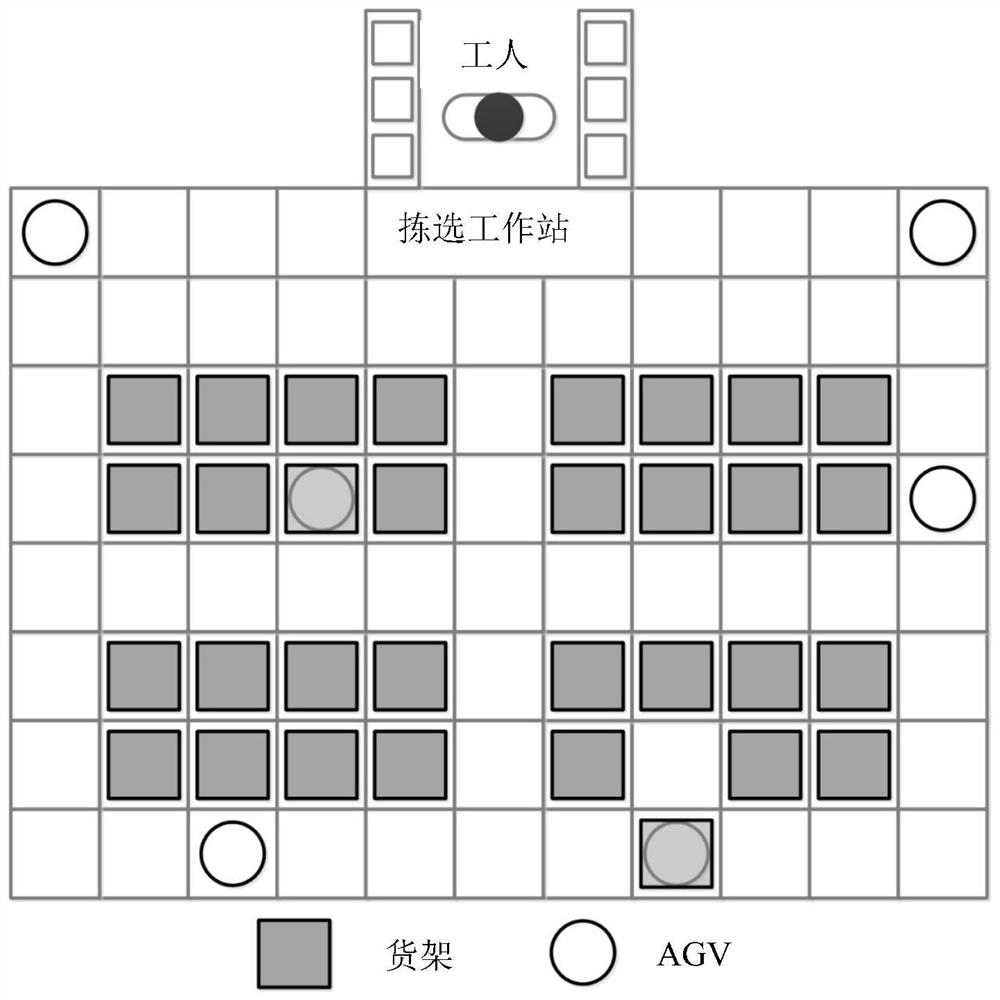

[0091] In this embodiment, two groups of calculation examples are used to test the performance of the AGV task scheduling method proposed by the present invention. In the first group of calculation examples, the limitation of AGV cruising range is not considered, while in the second group of calculation examples, the cruising range constraint of AGV is added. The floor of the intelligent storage system in the example is divided into 18 rows x 16 columns with a total of 288 cells. The location coordinates of the picking workstation are (1,8), and there are 120 movable shelves in the system storage area. The total number R of AGVs in the system is 5, 10, 15 respectively. The total number of shelf handling tasks J to be assigned is 15, 20, 30, 40, 45, and 60, respectively. 10 calculation examples of task scheduling problems are randomly generated under each parameter combination of R and J. In the second group of calculation examples, the number of AGVs with low, medium and hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com