Scanner coupling water supply system

A technology for a water supply system and a scanner, which is applied to water supply devices, water supply devices, instruments, etc., can solve the problems of affecting the safety and reliability of scanner operation, time-consuming and laborious, and poor safety, saving manpower and ensuring safety and reliability. , the effect of easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] First of all, it needs to be explained that the orientation words such as up, down, left, right, front, and back described in the present invention are only described according to the accompanying drawings, so as to be easy to understand, and are not intended to limit the technical solution and scope of protection of the present invention. .

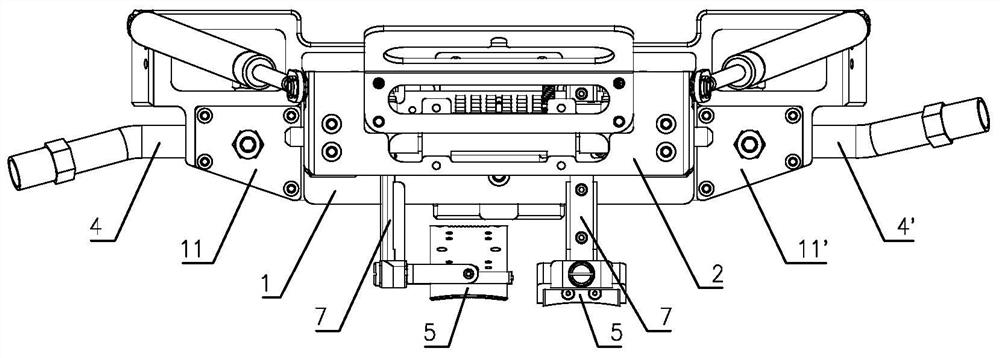

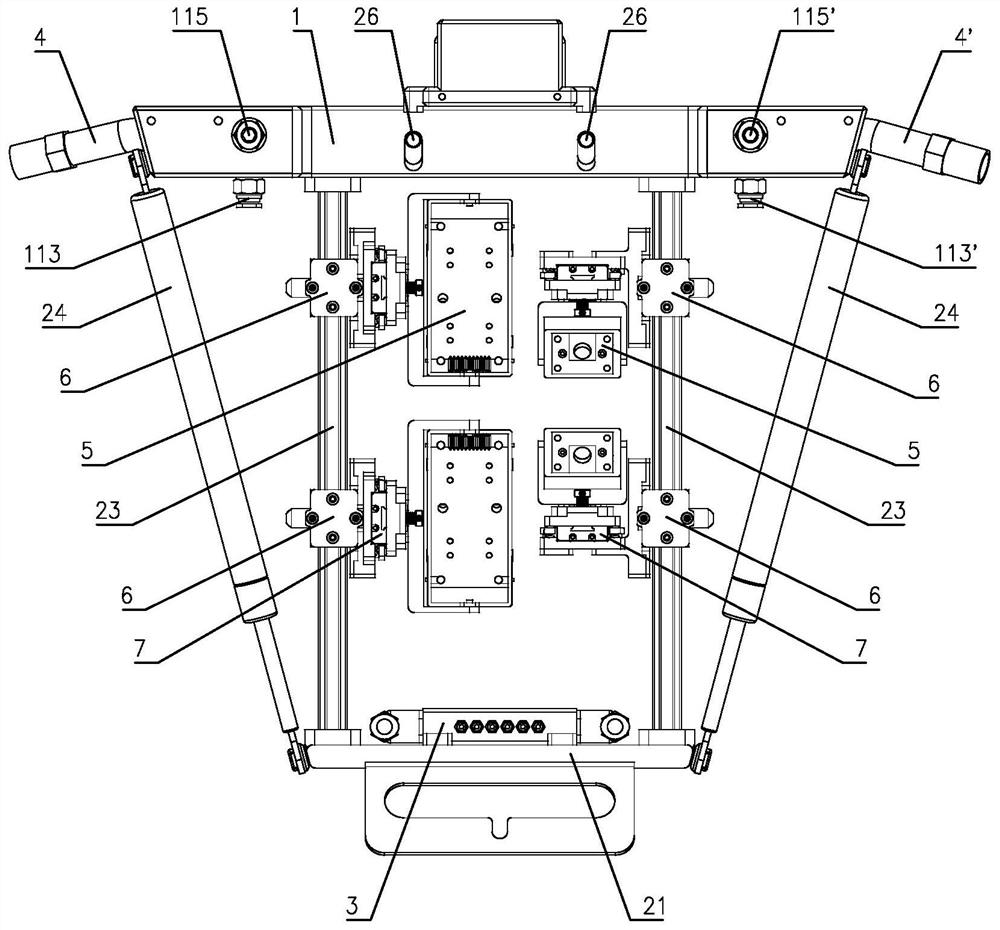

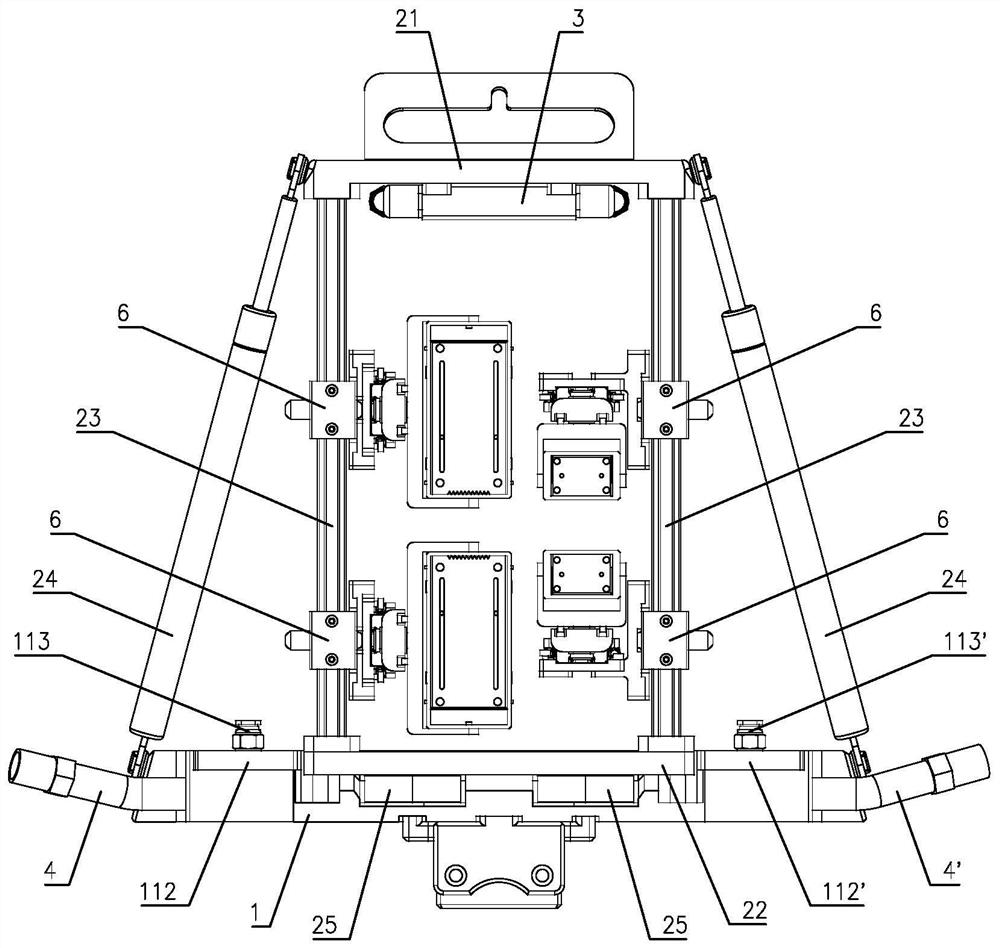

[0036] like Figure 1 to Figure 19Shown is a specific embodiment of a scanner coupling water supply system of the present invention, including a connection base 1 and a loading frame 2 installed on the front side of the connection base 1 , and a water separator 3 is arranged on the loading frame 2 . Make connecting seat 1 correspondingly set left cavity body 11 and right cavity body 11 ' at its left and right ends, let left cavity body 11 connect left water storage bottle (not shown in the figure) through left support tube 4; Let right cavity body 11 ' pass through The right support pipe 4' is connected to the right water storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com