Novel disinfection device for textiles

A disinfection device and textile technology, which is applied in the field of textiles, can solve the problems of dust raising, textile offset, dust falling again, etc., and achieve the effect of improving the cleaning effect and moving stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

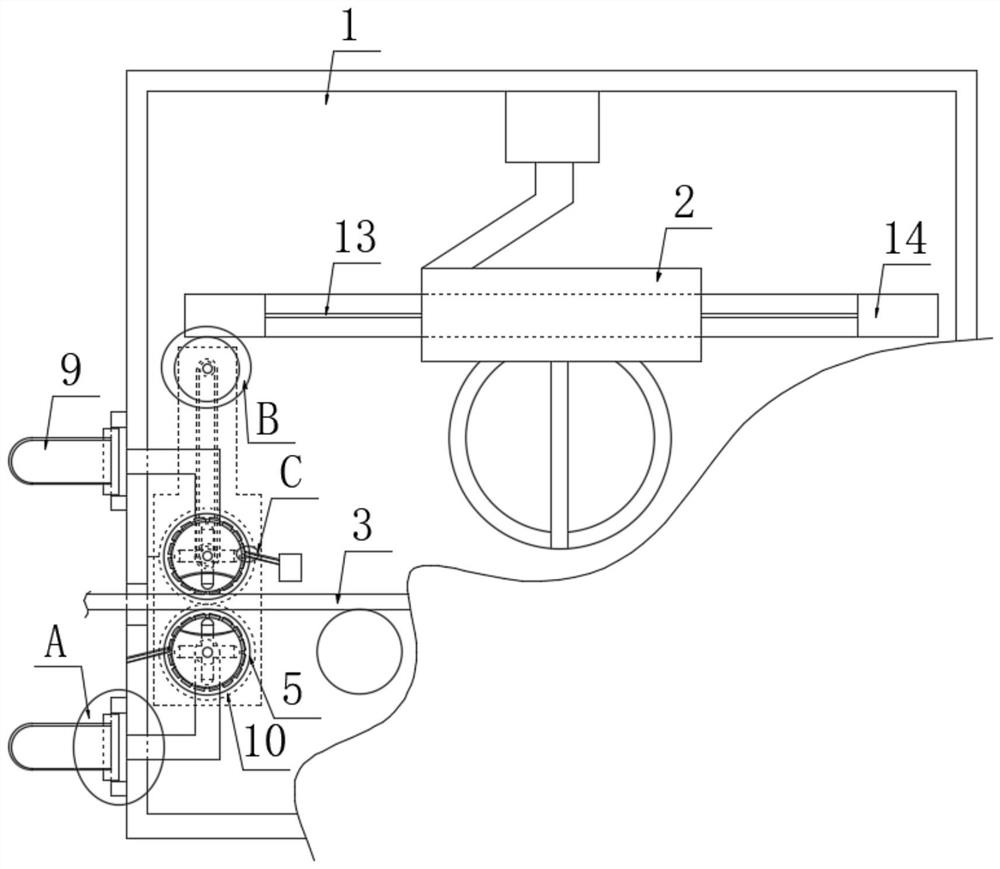

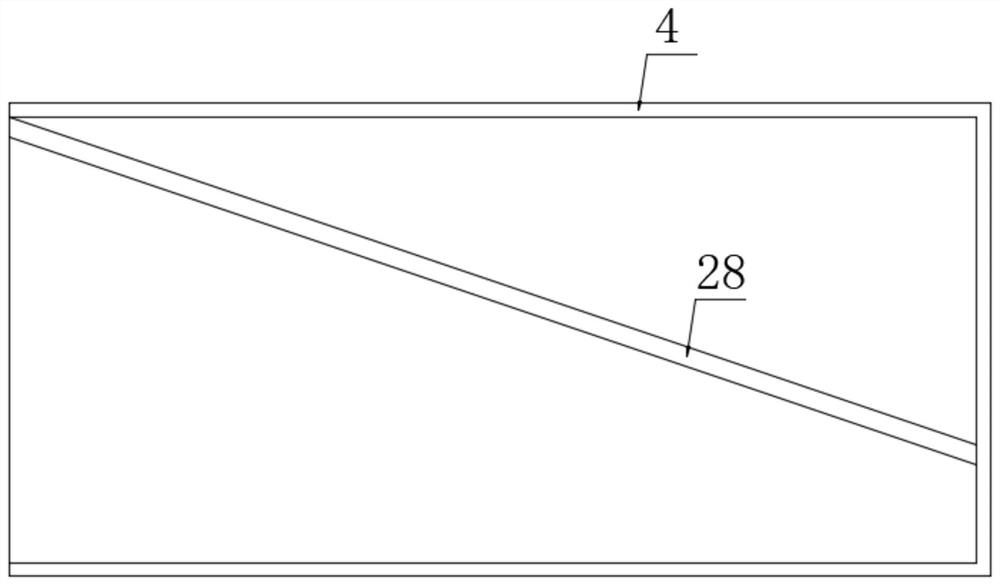

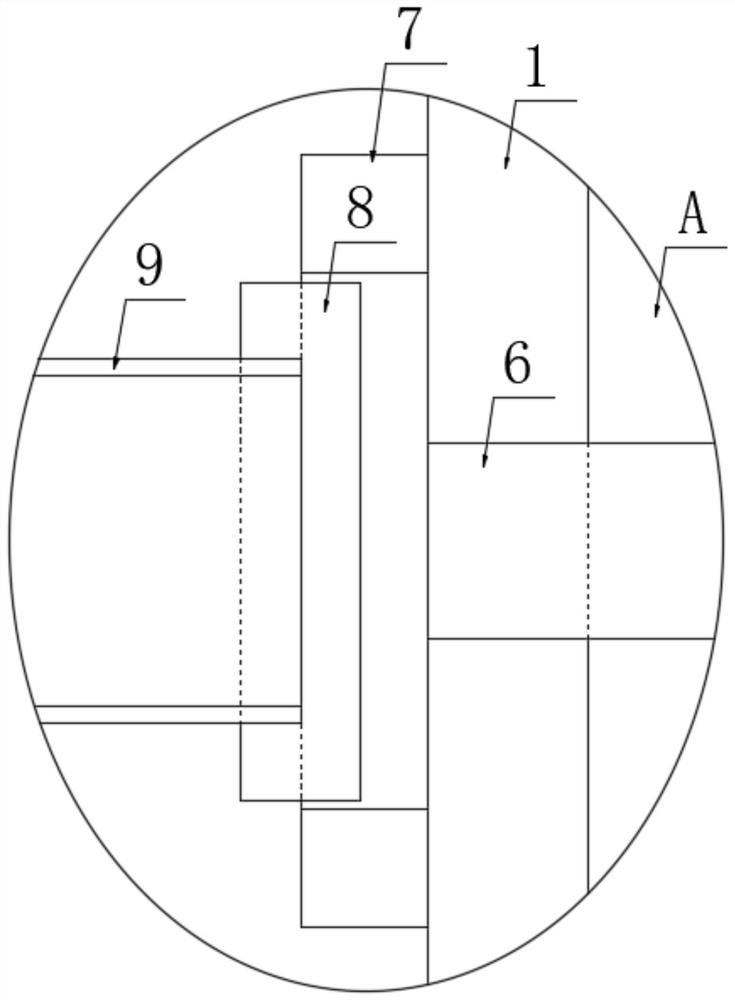

[0033] refer to Figure 1-5 , a new type of disinfection device for textiles, comprising a box body 1, a swivel 2, and a textile 3. The front inner wall of the box body 1 is installed with two dust removal rollers 4 by rotating two shafts, and the dust removal rollers 4 are located on the side of the textile 3. On both sides, the rear inner wall of the box body 1 is fixedly installed with two sealing discs 5 through a plurality of rods, and a fan blade 1 is fixedly installed on the two shafts 1, and the fan blade 1 is located in the corresponding dust removal roller 4;

[0034] There are two points worth noting above:

[0035] 1. The ends of the textiles 3 and the dust removal roller 4 away from the front side of the box body 1 are all rotatably mounted on the sealing disc 5 .

[0036] 2. The fan blade 1 can rotate with the rotation of the swivel ring 2, and the rotation of the fan blade can cause the flow of air flow, so that the dust removal roller 4 can generate the requir...

Embodiment 2

[0057] refer to Figure 6-8 The difference between this embodiment and the first embodiment is that the cleaning structure is composed of a cloth bag three, an installation cover 23, a dust collection cover 24, a rotating shaft two 25 and a fan blade two 27, and the inside of the box body 1 is fixed by three or four rods Two installation covers 23 are installed, and the side of the two installation covers 23 close to the dust removal roller 4 is fixedly connected with a dust suction cover 24, and the dust suction cover 24 is a hollow structure connected at both ends, and the installation cover 23 is far away from the dust removal roller 4 One side of each is fixedly connected with cloth bag three (not shown in the figure), and a rotating shaft two 25 is installed in two installation covers 23, and a fan blade two 27 is fixedly installed on the two rotating shafts two 25, two A linkage assembly is installed between the shaft two 25 and the shaft two; the linkage assembly is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com