New DIY technology of cloisonn enamel painting

A new process, enamel technology, applied in the process of producing decorative surface effects, decorative arts, special decorative structures, etc., can solve the problems of expensive finished products, long production cycles, and many processes, and achieve increased space and convenience. Craft and fun effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The technical solutions of the new technology will be clearly and completely described below in conjunction with specific implementation cases of this process. Obviously, the described implementation cases are only part of the description of the technology, not all implementation cases.

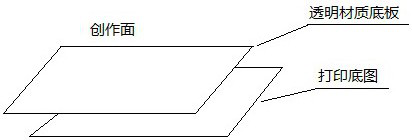

[0009] A new technique for making cloisonné enamel painting, comprising the following steps:

[0010] a. Material selection and preparation: Put the colored sand or glaze in small plates for later use, print out the film base map of the corresponding size with a color or black and white printer, and engrave the corresponding hollow shape with a plotter; then according to the lines in the picture Dispense glue and silk directly at the position, the glue here can be yellow shoe repair glue all-purpose glue, or transparent B\T-7000 glue;

[0011] b Sticky wire: After dotting the silk glue on the line position of the bottom plate, stick the gold wire (multi-color and multi-standard) on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com