A process for making vaginal electrodes

A manufacturing process and electrode technology, applied in the field of vaginal electrode manufacturing process, can solve the problems of low-cost output, low work efficiency, limitations of vaginal electrode manufacturing process, etc., and achieve high-efficiency and low-cost output and yield. And the effect of stable electrical conductivity and avoiding bumping the mold process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

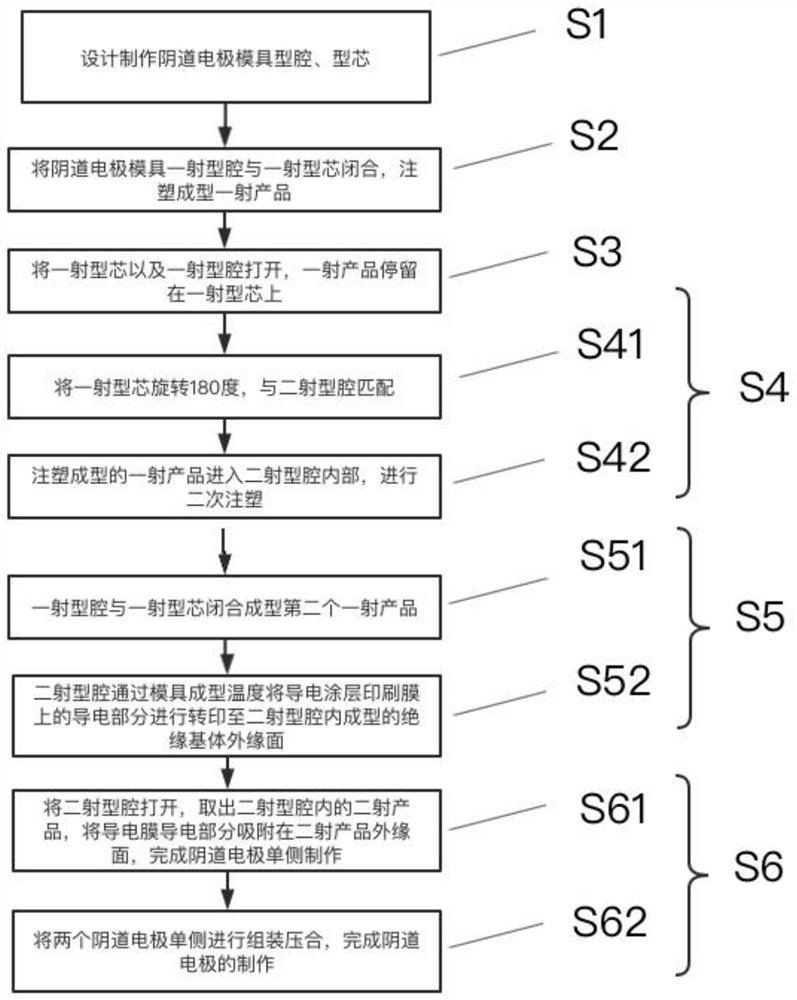

[0040] like Figure 1-2 As shown, as the first embodiment of the present invention, a manufacturing process of a vaginal electrode includes the following steps:

[0041] Step S1, designing and manufacturing a vaginal electrode mold with one-shot cavity, two-shot cavity, one-shot core and two-shot core, wherein the number of vaginal electrode molds is at least one, and each vaginal electrode mold includes at least one one-shot mold The cavity and at least one two-shot cavity are used for the production of vaginal electrodes. The one-shot cavity and the two-shot cavity are the same, the one-shot core and the two-shot core are the same, and the custom one-shot core is the one-shot cavity. The internal shape of the medium-molded product, and the two-shot core is the internal shape of the molded product in the two-shot cavity;

[0042] Step S2, closing the first-shot cavity and the first-shot core of the vaginal electrode mold, filling with conductive plastic, and injection-moldin...

no. 2 example

[0055] As the second embodiment of the present invention, a manufacturing process of a vaginal electrode, based on step S1 in the first embodiment, can use two independent sets of molds, the first set of molds is used for processing conductive plastics, and the second set of molds is used for processing conductive plastics. For processing the insulating base, the conductive plastic is put into the second set of molds before the insulating base is processed, and the conductive film is also put into the mold cavity at the same time.

no. 3 example

[0056] As the third embodiment of the present invention, a manufacturing process of a vaginal electrode, based on the in-film printing process adopted in the first embodiment, that is, the IMD process, can be replaced by the IMF process, that is, a single shot of conductive plastic is formed. With the half-sided single-sided finished product of the insulating substrate, the conductive film is attached to the surface of the single-sided finished product by using high temperature and high pressure to transfer the pattern layer on the film to the surface of the single-sided finished product to form a conductive single-sided finished product.

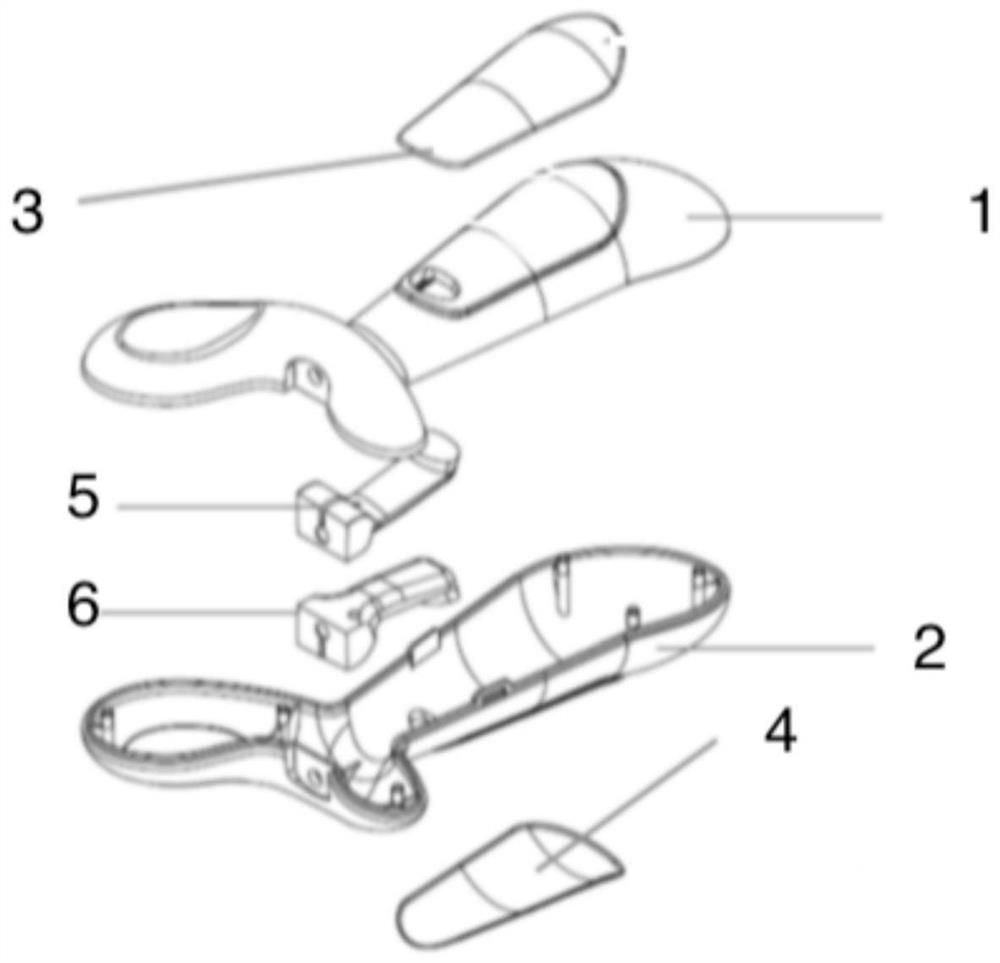

[0057] The vaginal electrode provided as an embodiment of the present invention includes an upper cover case 1, a lower cover case 2, and an accommodating space formed by the combination of the lower cover case 2 and the upper cover case 1, and the upper cover case 1 is relative to the outer surface of the accommodating space. A first conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com