A Second Tool Setting Method for 3+2 Axis Machine Tool Machining

A technology of secondary tool setting and machine tool, applied in metal processing, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of no re-confirmation and difficult tool setting for secondary tool setting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

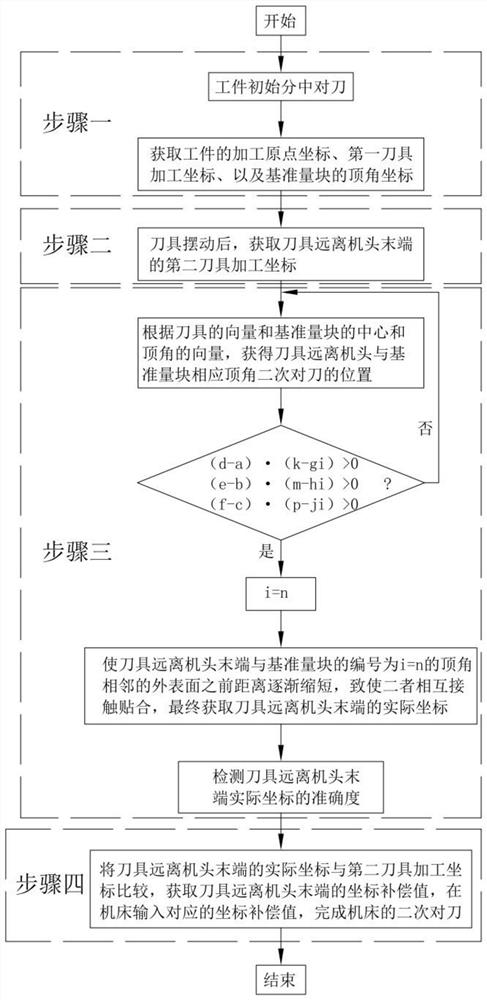

Method used

Image

Examples

Embodiment 2

[0072] The difference between embodiment two and embodiment one is:

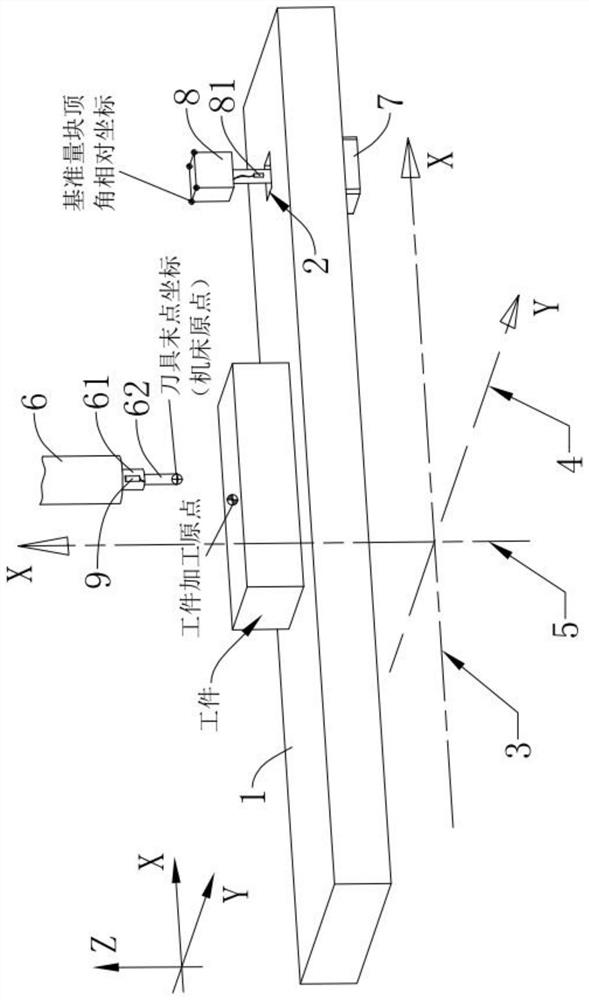

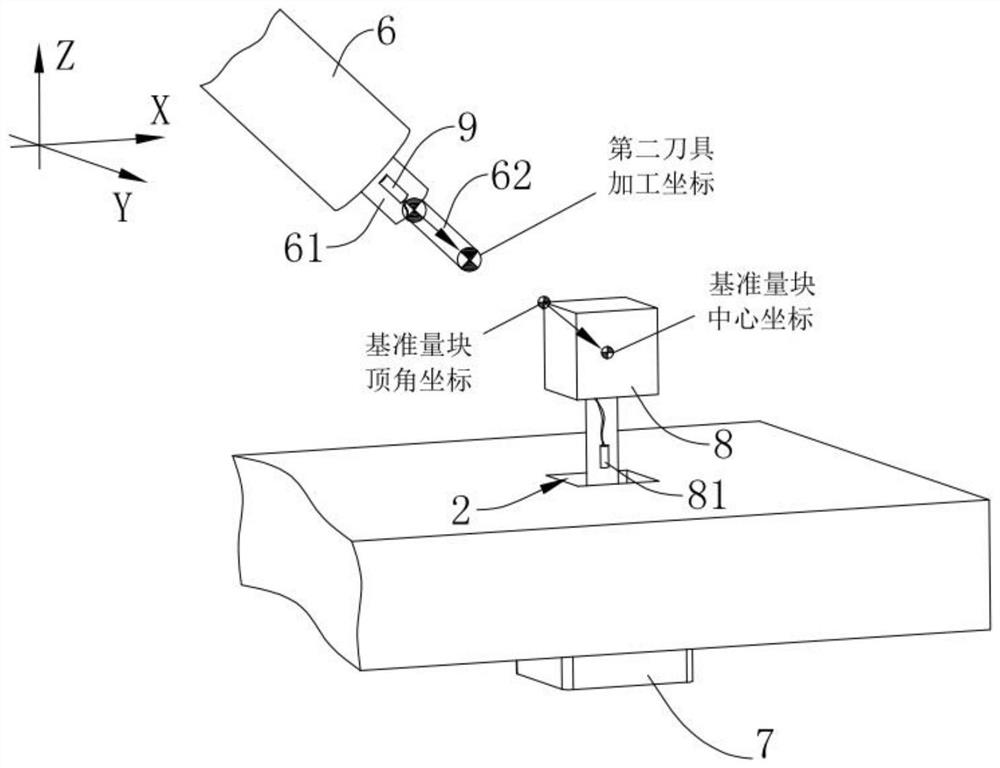

[0073] The 3+2-axis machine tool includes a support frame (not shown in the figure), the support frame is fixedly connected to the working platform 1, and the working platform 1 is embedded with a pusher, the pusher is the push cylinder 7, and the push cylinder 7 is completely accommodated and In the working platform 1, the protruding end of the pushing cylinder 7 is set perpendicular to the supporting surface of the working platform 1 toward the machine head 6, and the protruding end of the pushing cylinder 7 is fixedly connected with a reference gauge block 8, which is set in a cube. The three adjacent edges of any top angle of the gauge block 8 are respectively parallel to the length direction of the X-axis driving part 3, the Y-axis driving part 4 and the Z-axis driving part 5 of the machine tool. The supporting surface of the working platform 1 There is a storage slot 2 for inserting the reference gauge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com