Paper machine runner foam-free optimization system

A flow channel and foam technology, applied in the field of paper machine flow channel foam-free optimization system, can solve the problems of uneven paper scraps in the pulp, easy to affect the thickness of the paper, and affect the quality of the paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

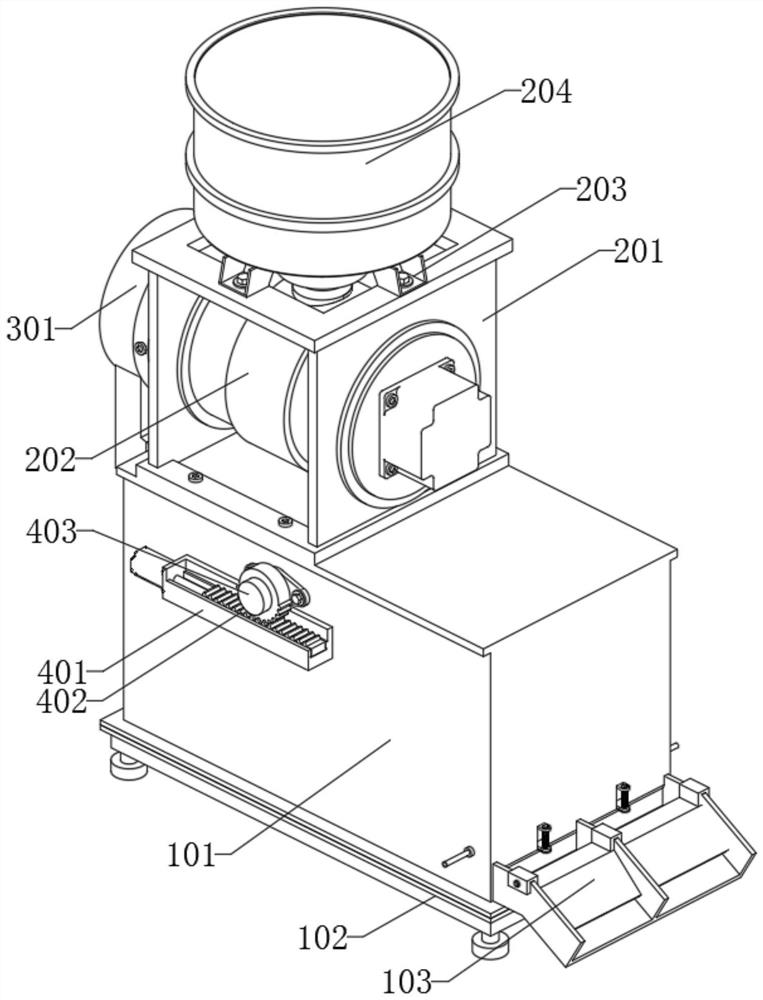

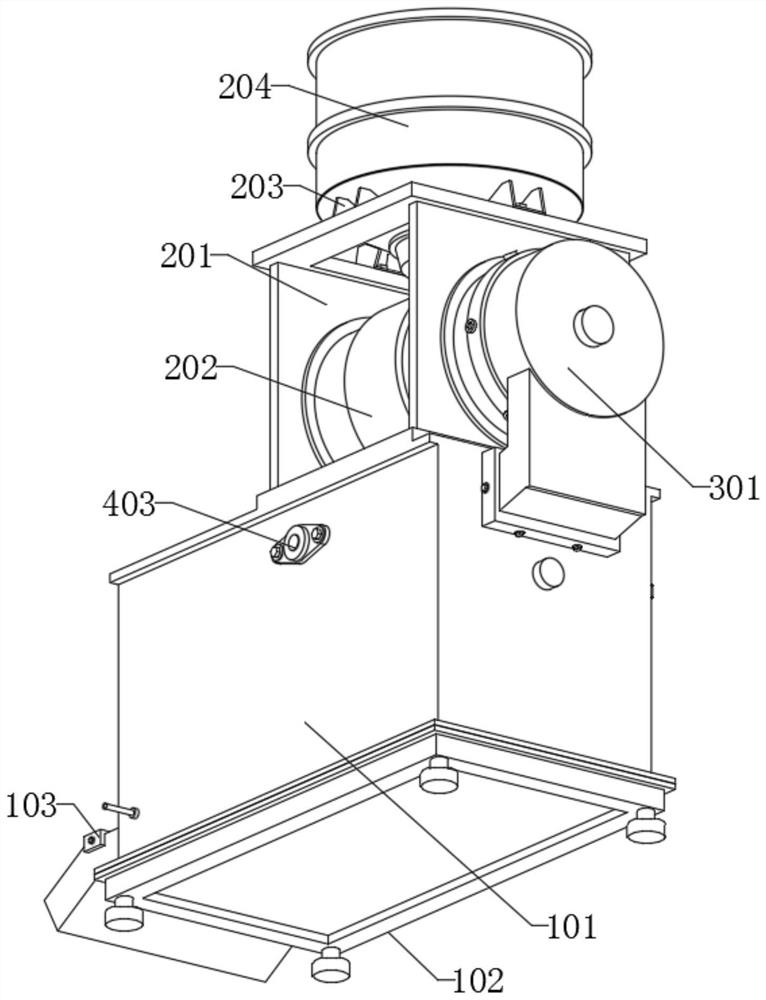

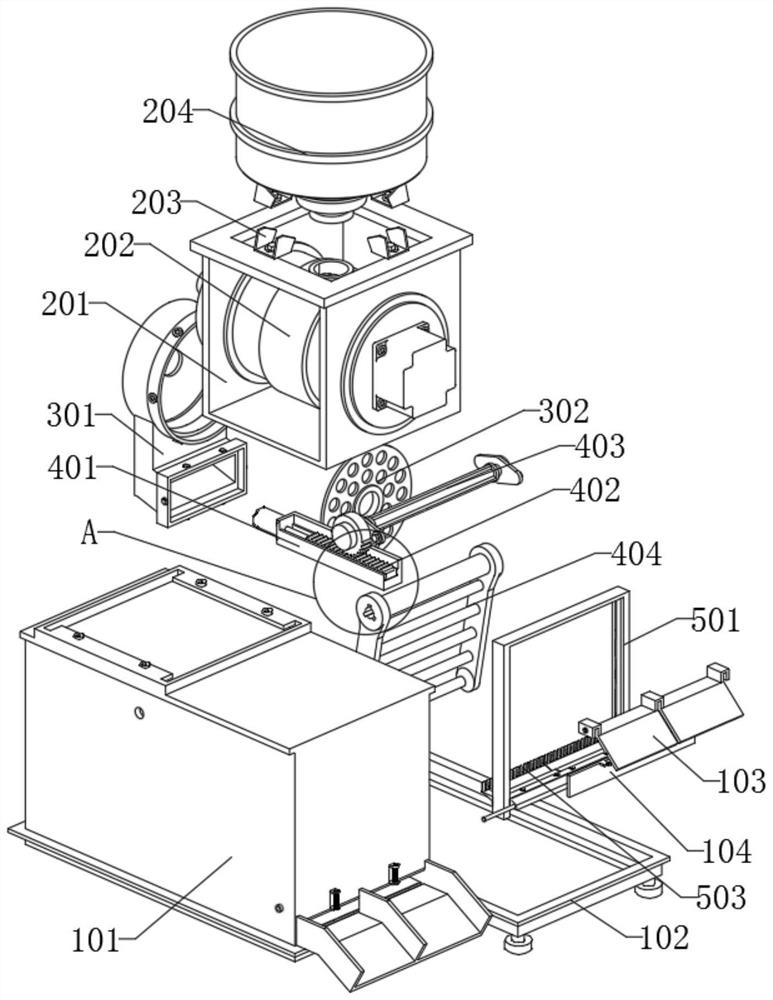

[0048] Example: please refer to Figure 1 to Figure 12 :

[0049] The present invention proposes a foam-free optimization system for a paper machine flow channel, including: a rinsing part 1, a conveying part 2, a drainage part 3, a swing part 4, and a de-foaming part 5; the rinsing part 1 includes: a main body 101, the main body 101 being the middle The hollow cuboid structure, the front side bottom of the main body 101 is provided with a rectangular through hole, the rear side of the main body 101 is provided with a rectangular through hole, the front side of the main body 101 is rotatably connected with a threaded rod, and the front side of the main body 101 is provided with an L-shaped drainage plate , the left and right sides of the main body 101 are provided with shaft holes; the main body 101 is used to install and fix other structures of the device, so as to facilitate the use of the device; the conveying part 2 is arranged on the top of the rinsing part 1, and the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com