Method for rapidly decreasing water-oxygen content of forming chamber in additive manufacturing process and system

A technology of additive manufacturing and water and oxygen content, applied in the direction of additive manufacturing, additive processing, etc., to achieve the effect of increasing social benefits, improving the degree of automation, and shortening the preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

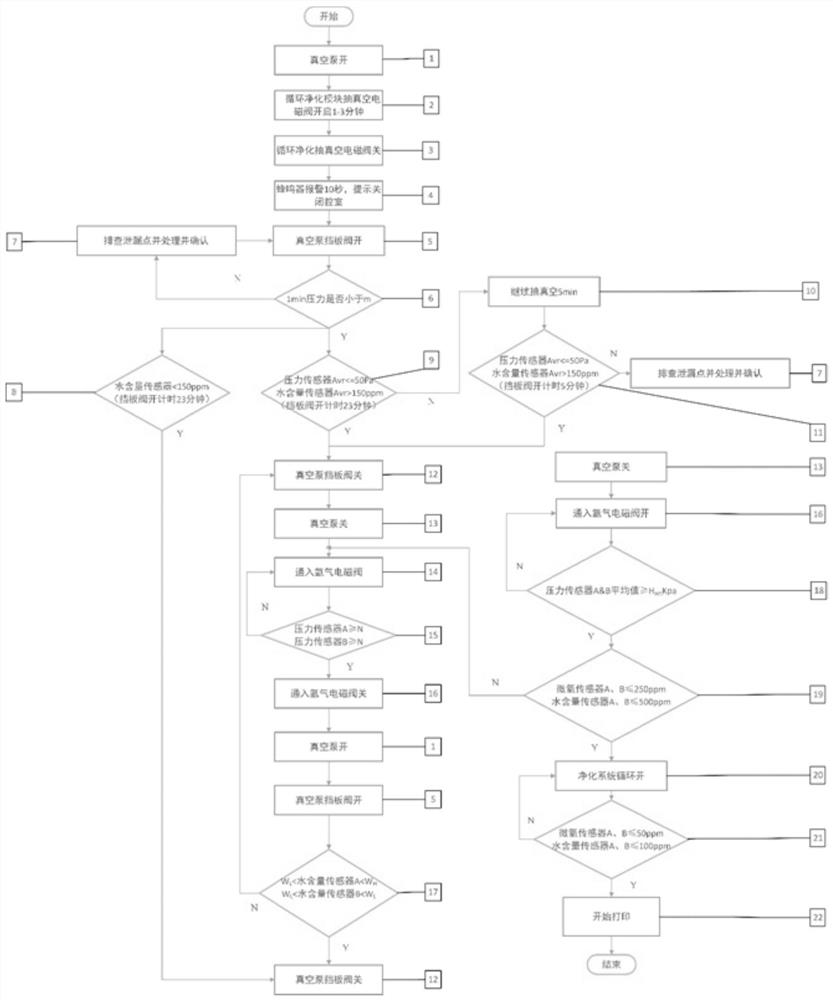

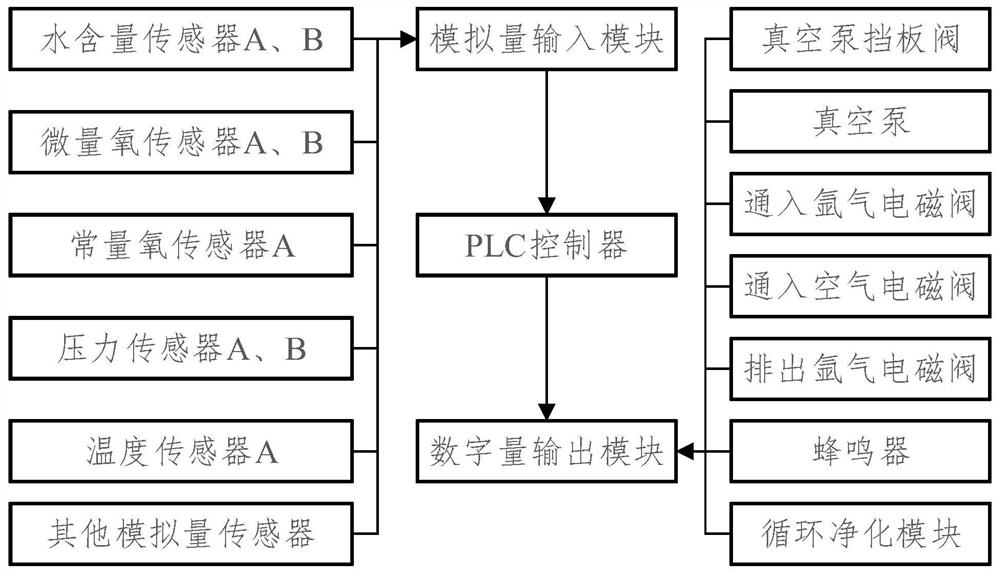

Method used

Image

Examples

Embodiment

[0041] In this embodiment, the internal volume of the sealed cavity is about 9.5m 3 , respectively select the following hardware according to the above system:

[0042] 1. Leybold large vacuum pump (5.5KW), 2. Chengdu Jiuyin constant oxygen sensor (0-25%), 3. Chengdu Jiuyin trace oxygen sensor (0-1000ppm), 4. Finnish Verasa dew point meter (0-25%) 1000ppm), 5. Star instrument pressure sensor (absolute pressure 0-120Kpa), 6. Thermocouple temperature sensor, 7. Siemens S7-1200PLC controller, 8. Analog input and output module, 9. Digital input and output, 10. Solenoid valve for SMC vacuum (1.2Mpa), 11.20Kg copper catalyst purification column, 12. Equipment status warning device (with three-color light and buzzer), 13. Siemens HMI display screen, equipment sealing test before the experiment, pumping Vacuum to 100Pa, keep the pressure for one hour, the internal cavity pressure is ≤200Pa, the test can only be continued if the conditions are met, if the conditions are not met, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com