Device suitable for flushing surface of spent fuel dry-method storage container

A storage container, surface flushing technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve problems such as the inability to ensure that the container surface is flushed in place, the radiation level of storage containers is increased, and large-scale industrial safety risks. , to achieve the effect of convenient and fast equipment installation, reduction of collective dose, and reduction of exposure dose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A device suitable for flushing the surface of a spent fuel dry storage container provided by the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

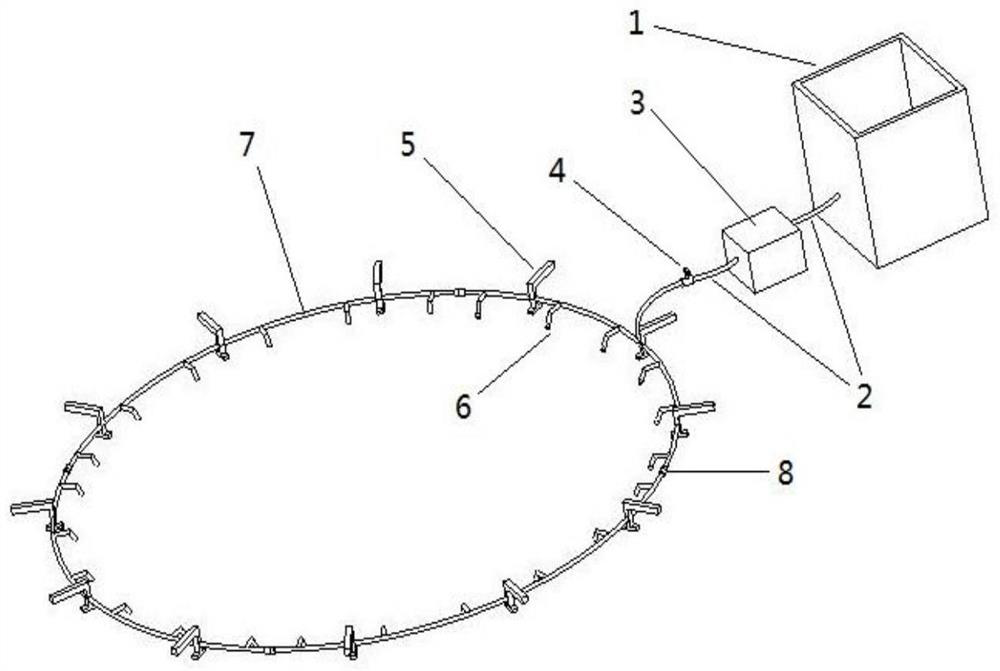

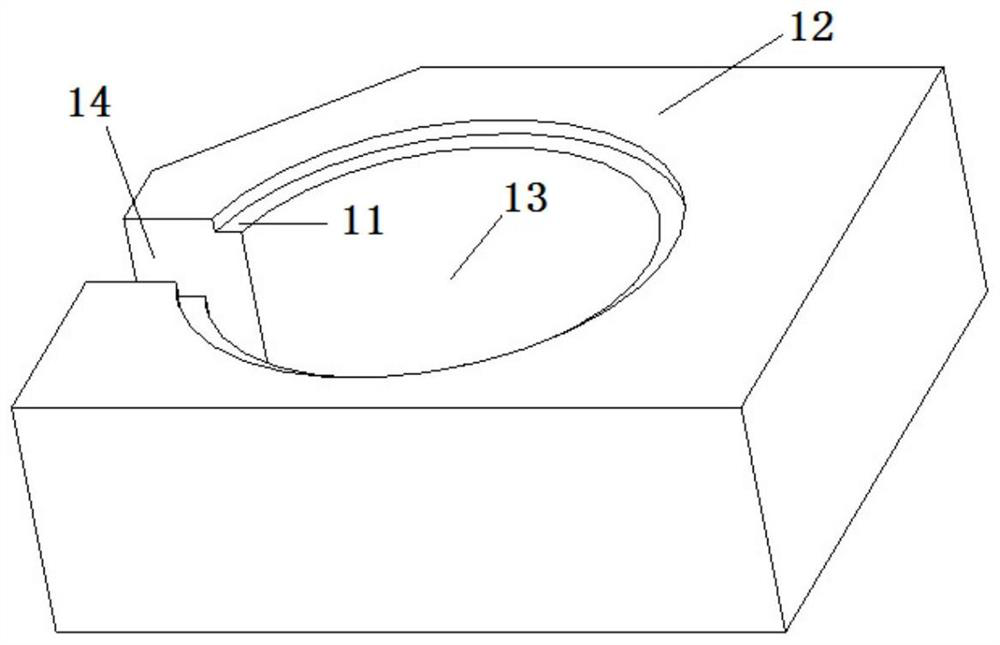

[0024] like figure 1 As shown in the figure, a device suitable for surface washing of spent fuel dry storage containers provided by the present invention has the characteristics of light structure, easy installation, handling and disassembly, etc. image 3 The shown spent fuel pool refueling well includes flushing water tank 1, connecting hose 2, flushing water pump 3, pressure regulating switch 4, flushing bracket 5, flushing nozzle 6, flushing pipe 7, quick connector 8;

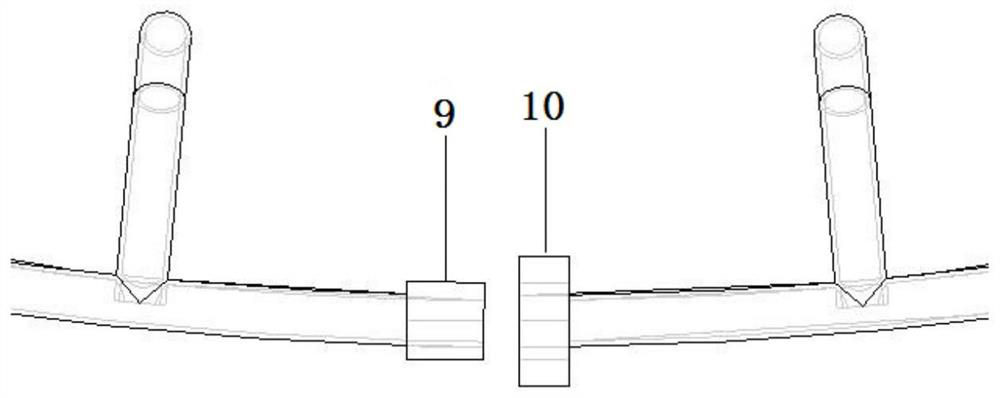

[0025] The flushing pipe 7 is in the shape of 1 / 4 circle, and the four flushing pipes 7 form a circular loop. The flushing pipe 7 is provided with a flushing nozzle 6, and each flushing pipe 7 has three flushing brackets 5, which are used to fix the On the inner edge 11 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com