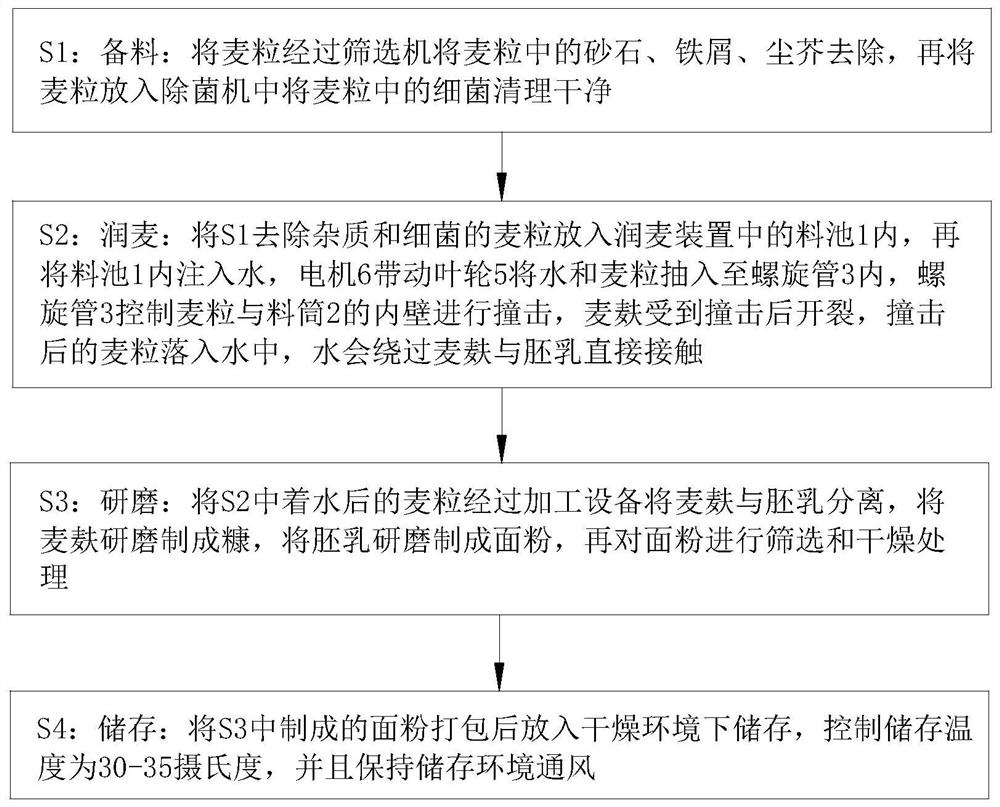

Flour processing method

A processing method and flour technology, which is applied in the directions of grain finishing, grain milling, and grain germ removal, can solve the problems of affecting the flour extraction rate of wheat grains, affecting the separation effect of endosperm and wheat bran, and affecting production efficiency, so as to improve the production efficiency. Endosperm wetting effect, improved separation effect and flour extraction rate, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

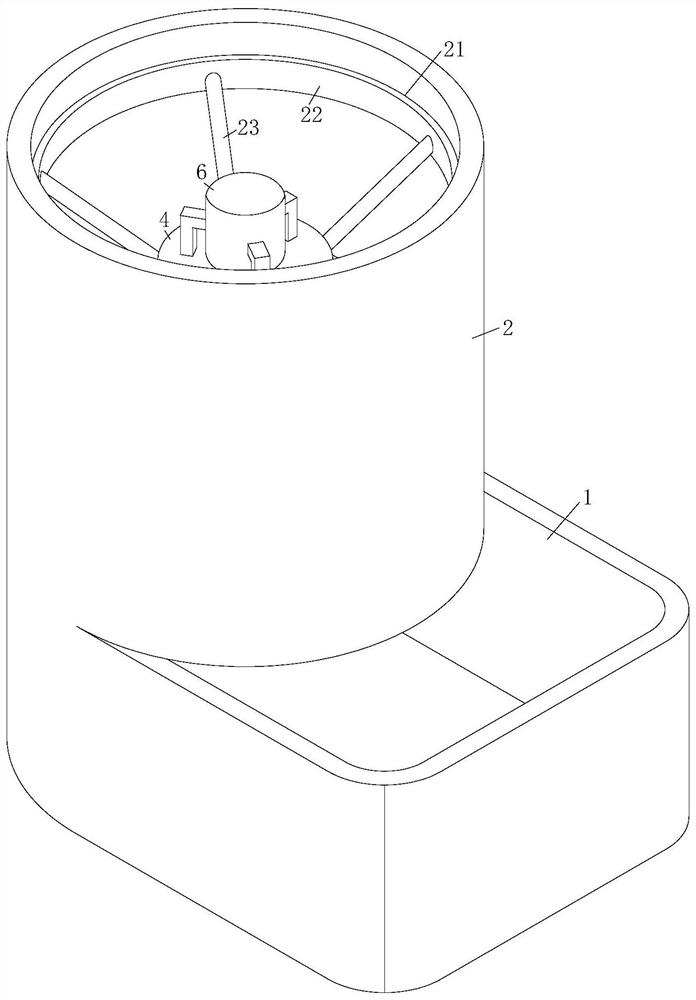

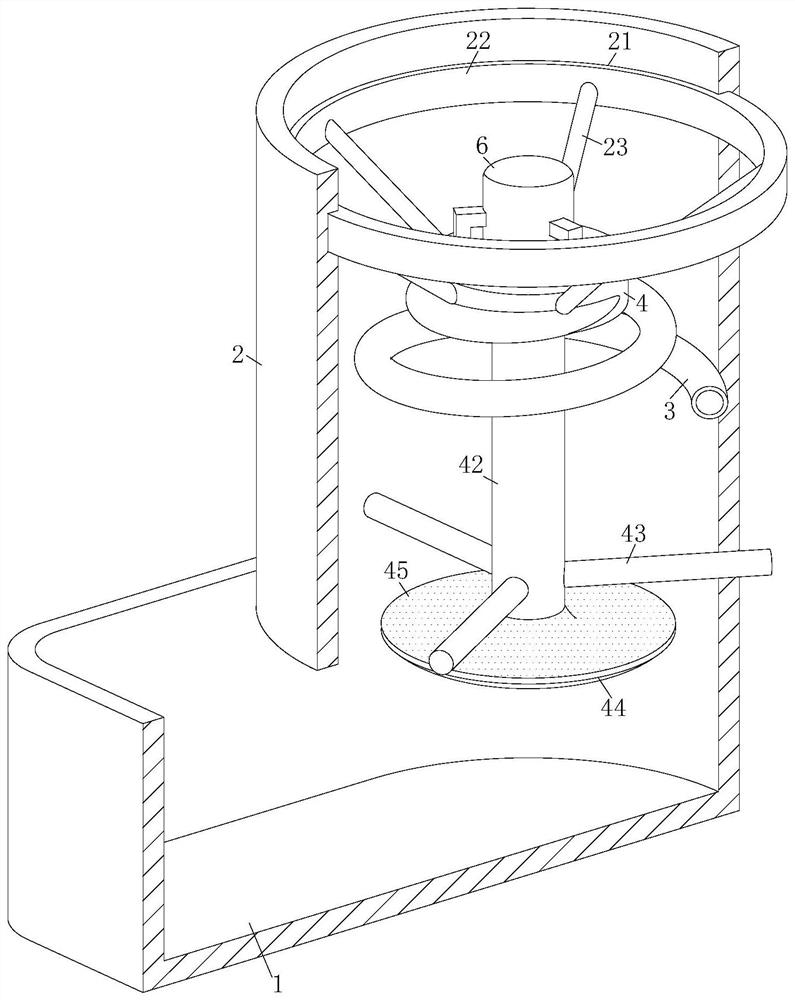

[0040] As an embodiment of the present invention, a group of stoppers 71 are fixedly connected to the inner surface of the spiral plate 7; the number of the stoppers 71 is at least three, and the cross-sectional shape of the stoppers 71 is a right triangle, and the adjacent stoppers 71 The distance between them increases as they get closer to the bottom of the barrel 2; when in use, the time for the wheat grains to stay along the spiral plate 7 is limited, so that the time for oxygen and endosperm fermentation is limited; therefore, in the present invention, the wheat grains fall on the spiral plate 7, because the inner surface of the spiral plate 7 is fixedly connected with a stopper 71, thereby increasing the friction force between the wheat grain and the inner surface of the spiral plate 7 by the stopper 71, and then increasing the friction of the wheat grain on the spiral plate 7. The residence time allows oxygen to fully enter the endosperm, and the distance between adjace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com