Multistage sedimentation rake-free concentration device capable of uniformly distributing materials

A technology of uniform distribution and concentration device, applied in the feeding/discharging device of sedimentation tank, sedimentation tank, dehydration/drying/concentrated sludge treatment, etc. The problem of poor sedimentation effect, etc., can improve the deterioration of the washing process, achieve sufficient separation, and facilitate sedimentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

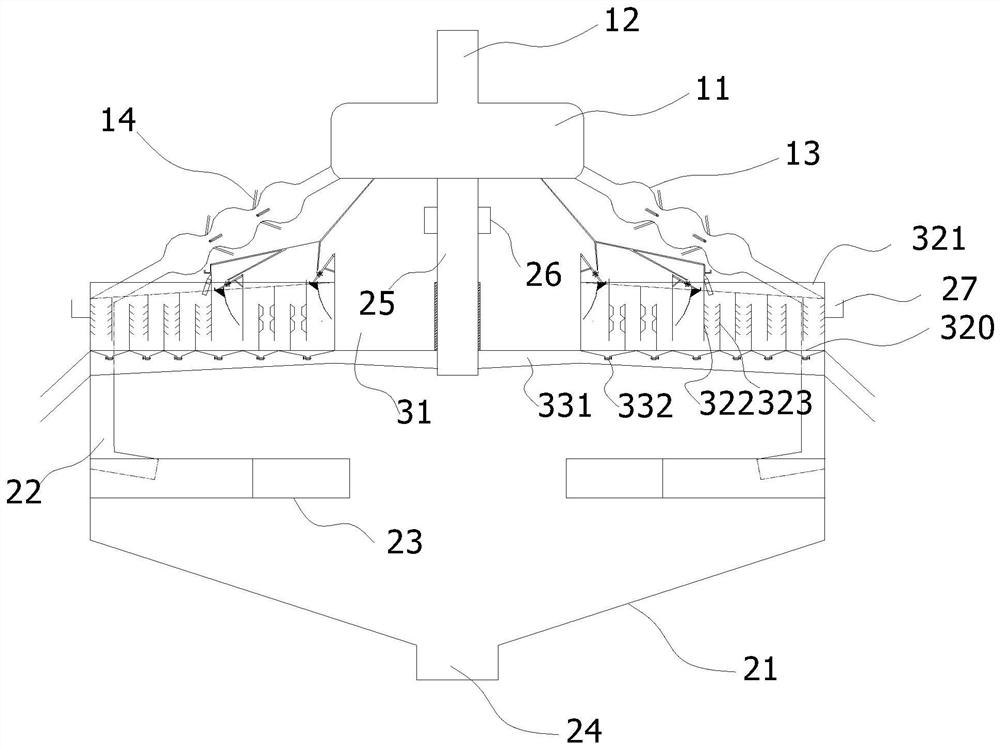

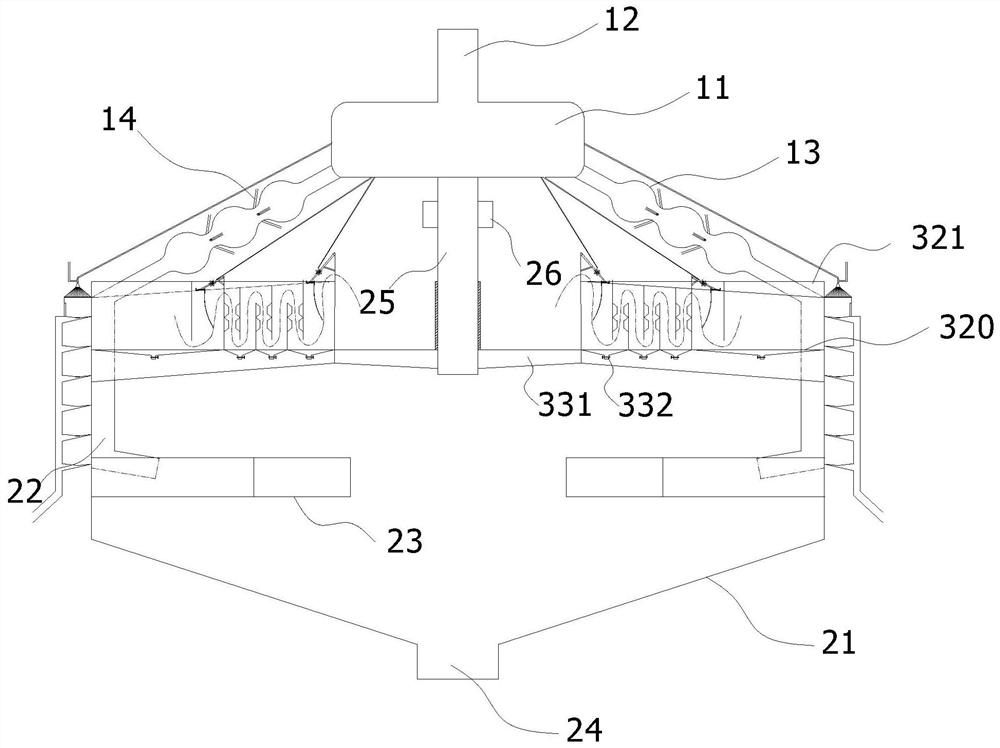

[0047] The utility model relates to a multi-stage subsidence rakeless thickening device with uniform distribution, which includes a material feeding component, a diversion component, and a clean coal collecting component. The guide assembly includes a central tank 21 with a cylindrical portion at the upper end and a funnel at the lower end. The central tank 21 is a cavity structure, and the feeding assembly is arranged above the cavity of the central tank 21. The central tank The lower end of the body 21 is provided with a first discharge port 24 . The coarse coal slime gradually settles to the top of the first discharge port 24 of the central tank 21 and deposits to a certain amount, and is discharged through the first discharge port 24, and the material discharged from the first discharge port 24 is collected , used for medium coal blending or as building materials to increase economic income.

[0048] like figure 1 As shown, the materials and medicaments enter the guide a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com