Preparation method of skin-moistening and anti-wrinkle cosmetic

An anti-wrinkle cosmetic and its mass fraction technology are applied in the field of preparation of emollient and anti-wrinkle cosmetic products to achieve the effects of scavenging free radicals, inhibiting lipoxygenase and lipid peroxidation, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

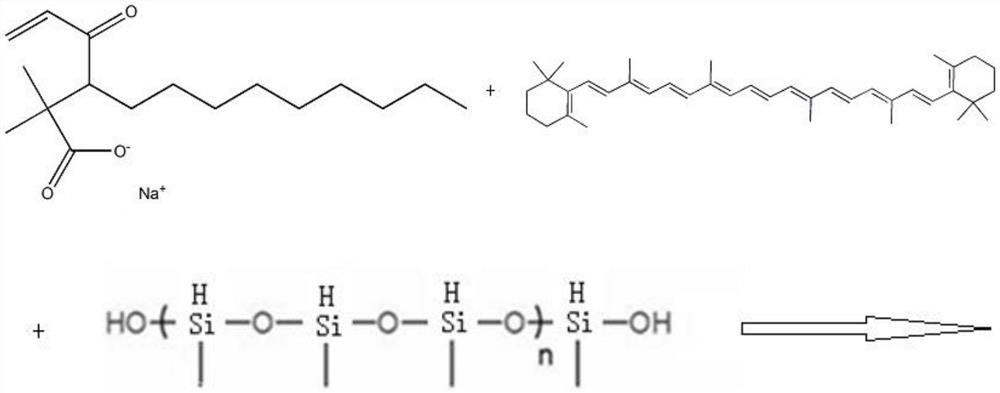

[0037] Step 1: Add 55g of squalane and 10g of silyl carotene into container A, heat to 75°C, stir at 133r / min for 20min, and obtain mixed solution A;

[0038]Step 2: Add 10g glycerin, 2g polyoxyethylene hydrogenated castor oil, 0.5g fumed silica, 0.5g sodium hyaluronate, and 100g deionized water into container B, heat to 85°C, stir at 100r / min for 20min, then cool down to 75°C to obtain the mixed solution B;

[0039] Step 3: Add the mixed solution B into the vacuum homogenization tank, then slowly add the mixed solution A into the mixed solution B stirred at 50r / min, control the temperature at 70°C, and then homogeneously emulsify at a speed of 500r / min for 3min, Stir at a speed of 50r / min, cool down to 35°C, and obtain a pre-emulsion;

[0040] Step 4, add 0.3g collagen, 0.3g dehydroepiandrosterone, 0.3g free radical scavenger, 0.05g paraben, 0.08g lemon flavor to the pre-emulsion, 50r / min, 35°C Stir for 30 minutes to obtain an emulsion, and age for 1 day to obtain a moistur...

Embodiment 2

[0047] Step 1: Add 56.2g of squalane and 11.3g of silyl carotene into container A, heat to 77.4°C, stir at 153r / min for 24.4min, and obtain mixed solution A;

[0048] Step 2: Add 10.5g of allantoin, 2.3g of polyoxyethylene hydrogenated castor oil, 0.5g of fumed silica, 0.5g of sodium hyaluronate, and 104.4g of deionized water into container B, heat to 87.2°C, 120r / min Stir for 22.8min, then lower the temperature to 76°C to obtain the mixed solution B;

[0049] Step 3: Add the mixed solution B into the vacuum homogenization tank, then slowly add the mixed solution A into the mixed solution B stirred at 60r / min, control the temperature at 71.6°C, and then homogeneously emulsify at a speed of 620r / min for 3.9min , stirred at a speed of 60r / min, and cooled to 36°C to obtain a pre-emulsion;

[0050] Step 4: Add 0.4g aloe vera gel, 0.4g dehydroepiandrosterone, 0.3g free radical scavenger, 0.05g phenylethyl alcohol, and 0.09g rose essence to the pre-emulsion, stir at 65r / min, 37.4°C...

Embodiment 3

[0057] Step 1: Add 57.2g of squalane, 12.4g of silyl carotene and 0.5g of dimethylsiloxane into container A, heat to 78.4°C, stir at 167r / min for 26.4min, and obtain mixed solution A;

[0058] Step 2: Add 11.2g of glycerin, 2.6g of polyoxyethylene hydrogenated castor oil, 0.5g of fumed silica, 0.5g of sodium hyaluronate, and 109.6g of deionized water into container B, heat to 88.8°C, and stir at 140r / min for 28min , and then lower the temperature to 78.8°C to obtain the mixed solution B;

[0059] Step 3: Add the mixed solution B into the vacuum homogeneous tank, then slowly add the mixed solution A to the mixed solution B stirred at 77r / min, control the temperature at 74.2°C, and then homogeneously emulsify at a speed of 730r / min for 5.1min , stirred at a speed of 75r / min, and cooled to 37.2°C to obtain a pre-emulsion;

[0060] Step 4: Add 0.5g seabuckthorn oil, 0.4g dehydroepiandrosterone, 0.5g free radical scavenger, 0.05g phenoxyethanol, 0.1g apple flavor to the pre-emulsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com