Manufacturing method of photovoltaic module

A manufacturing method and technology of photovoltaic modules, applied in photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of difficult rework, high stress, high cost of conductive adhesive materials, etc. The effect of implementing and reducing the risk of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present application will be described in detail below in conjunction with the implementations shown in the accompanying drawings. However, this embodiment does not limit the present application, and any structural, method, or functional changes made by those skilled in the art according to this embodiment are included in the protection scope of the present application. Wherein, "first" and "second" do not represent any sequence relationship, but are only distinguished for convenience of description. Those of ordinary skill in the art can understand the specific meanings of the above terms in this application in specific situations.

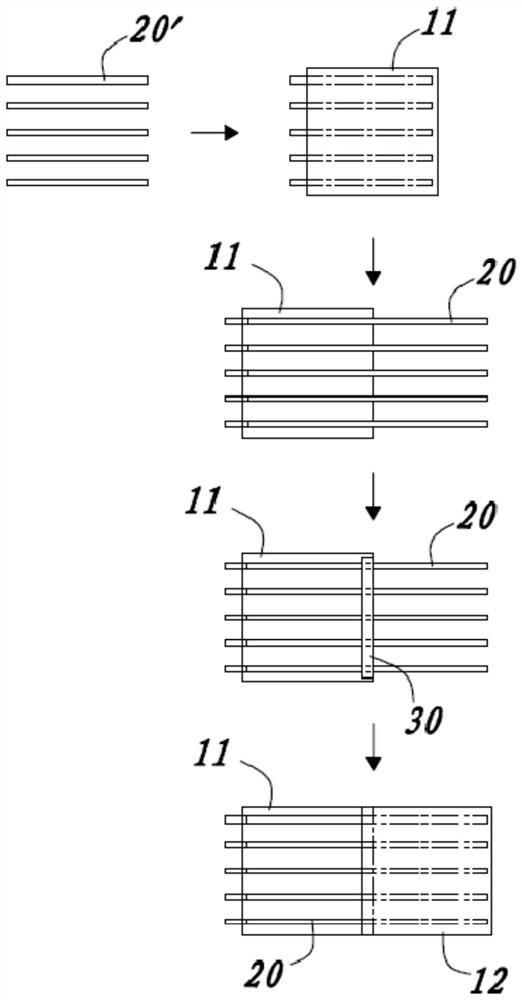

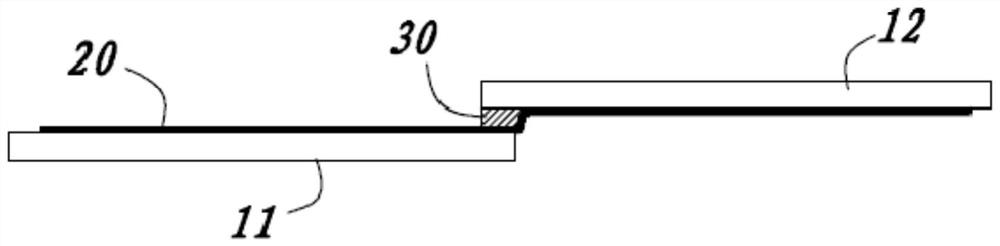

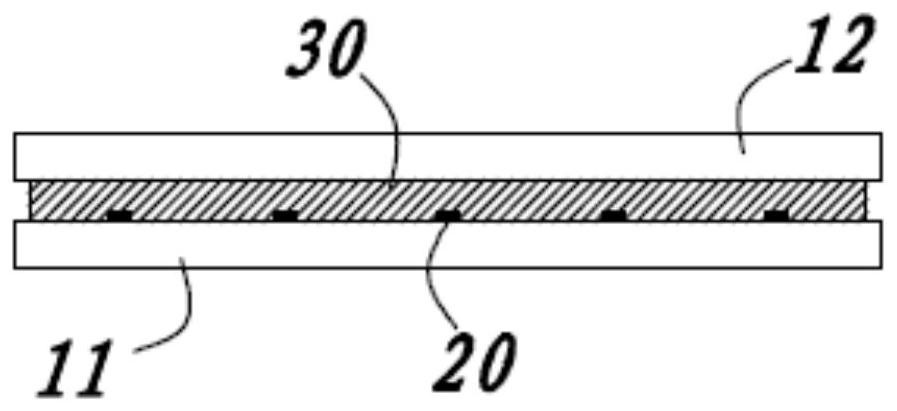

[0035] The manufacture of photovoltaic modules generally includes steps such as cell string preparation, lamination, installation of junction boxes, and testing. The method for manufacturing photovoltaic modules provided in the embodiments of this application aims to optimize the design of the cell string preparation steps and reduce th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com