Air circulation type liquid collecting pool heat taking method

A technology of air circulation and liquid collection pool, which is applied in heating methods, space heating and ventilation, direct contact heat exchangers, etc., and can solve problems such as strong corrosion, increased operating costs, and low temperature of ground immersion liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

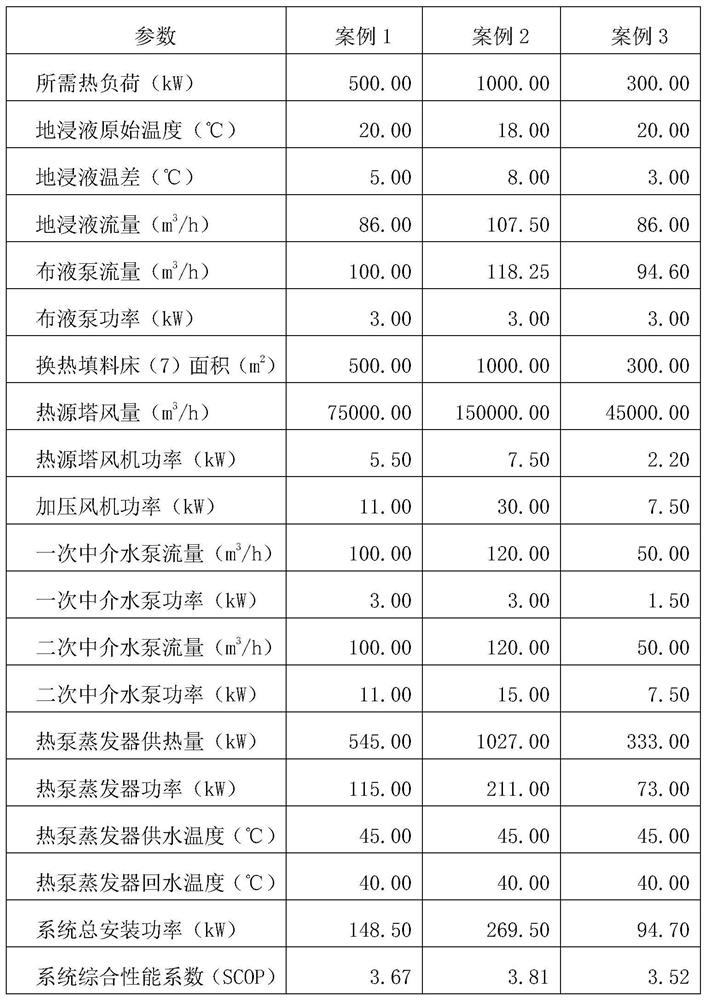

Examples

specific Embodiment approach

[0044] Specific implementation, the steps are:

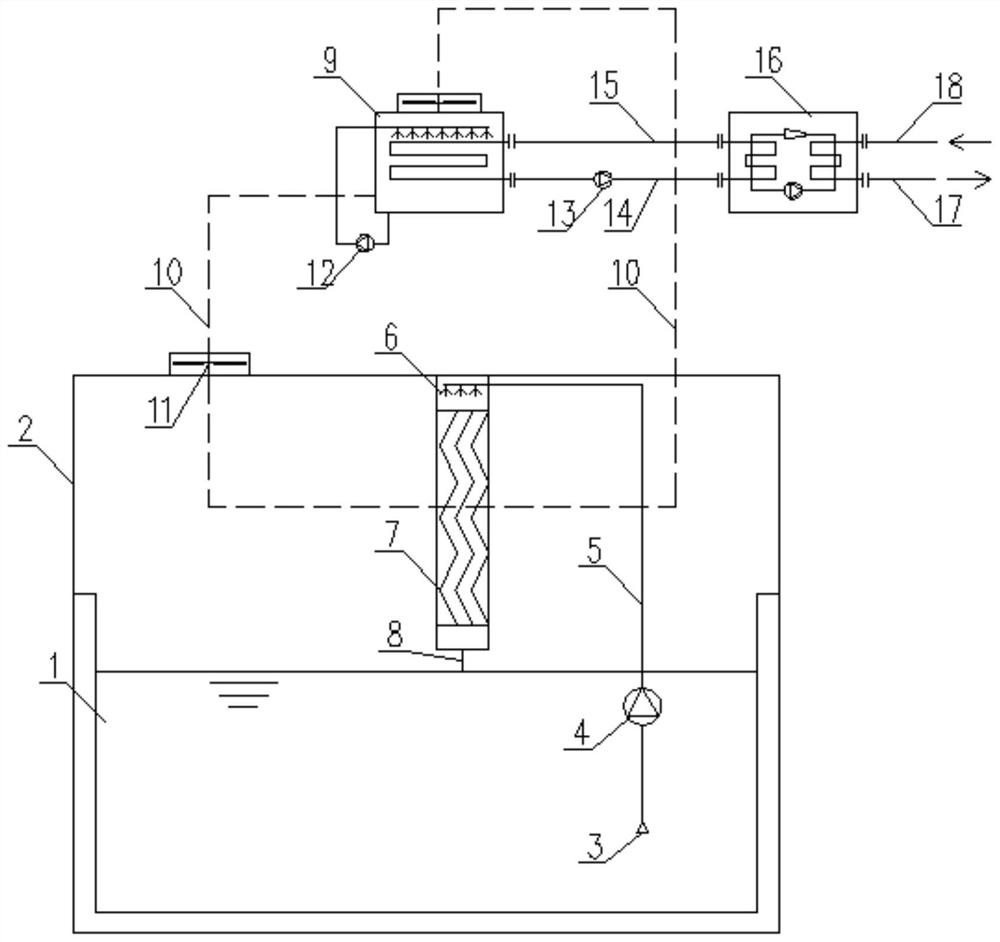

[0045] (1) Arrange the heat exchange packing bed, and arrange a certain number of PVC water-sprinkling packing layers on the ground immersion liquid pool.

[0046] (2) Rinse the packing bed, use the liquid distribution pump and the water distribution plate to evenly rinse the ground soaking liquid on the packing bed.

[0047] (3) The first air-water heat exchange, using the heat source tower as the power, makes the low-temperature air pass through the packing bed, and conducts the shallow ground heat to the circulating air through the packing.

[0048] (4) The second air-water heat exchange, using the pressurized fan as the power, transports the fully heated circulating air to the closed heat source tower for heat exchange between the air and the primary intermediate water.

[0049] (5) Water-water heat exchange, with the primary intermediate water pump as the power, the heat of the primary intermediate water is transferred to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com