Light aggregate concrete plate with flat and smooth surface and preparation method thereof

A technology of light aggregate concrete and smooth surface, applied in the field of building materials, can solve the problems of unfavorable environmental protection and economy, density increase, etc., and achieve the effect of avoiding light aggregate floating, low density, and reducing manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

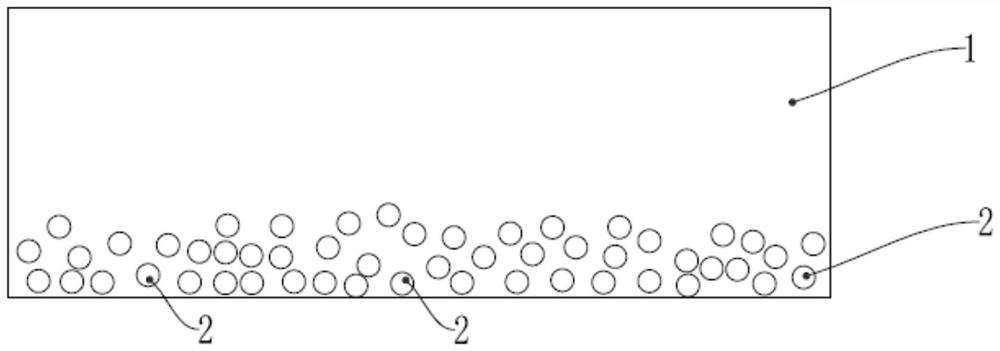

[0045] The lightweight aggregate concrete slab of this embodiment, such as figure 1 As shown, it includes a plate main body 1 and a magnetic light aggregate 2, and the magnetic light aggregate 2 is distributed on the bottom of the plate main body 1 through the guidance of a magnetic device. The preparation process is as follows:

[0046] A. Preparation of the magnetic light aggregate 2

[0047] Step A1, according to the mass percentage, mix and stir 5% hydroxypropyl methylcellulose, 3% sodium tripolyphosphate, 3% thermosetting water-based acrylic resin and 89% water at a stirring speed of 800 rpm, and homogenize into the first solution;

[0048] Step A2, adding nano-ferric iron tetroxide with a particle size of 10nm to the first solution in a small number of times, and then ultrasonically dispersed at 40KHz and 100W, and stirred continuously for 1 hour at a stirring speed of 600rpm to obtain a uniform first solution. Two solutions, the concentration of nano ferric oxide in th...

Embodiment 2

[0056] The lightweight aggregate concrete slab of this embodiment, such as figure 1 As shown, it includes a plate main body 1 and a magnetic light aggregate 2, and the magnetic light aggregate 2 is distributed on the bottom of the plate main body 1 through the guidance of a magnetic device. The preparation process is as follows:

[0057] A. Preparation of the magnetic light aggregate 2

[0058] Step A1, according to the mass percentage, 2% sodium carboxymethylcellulose, 4% sodium hexametaphosphate, 1% thermosetting water-based acrylic resin and 93% water were mixed and stirred at a stirring speed of 700 rpm, and homogenized into the first solution;

[0059] Step A2, adding nano-ferric iron tetroxide with a particle size of 50nm to the first solution in a small number of times, and then ultrasonically dispersed at 30KHz and 150W, and stirred continuously for 24 hours at a stirring speed of 400rpm to obtain a uniform first solution. Second solution, the concentration of nano fe...

Embodiment 3

[0067] The lightweight aggregate concrete slab of this embodiment, such as figure 1 As shown, it includes a plate main body 1 and a magnetic light aggregate 2, and the magnetic light aggregate 2 is distributed on the bottom of the plate main body 1 through the guidance of a magnetic device. The preparation process is as follows:

[0068] A. Preparation of the magnetic light aggregate 2

[0069] Step A1, according to the mass percentage, mix and stir 1% hydroxyethyl methyl fiber, 1% water glass, 2% thermosetting water-based acrylic resin and 96% water at a stirring speed of 400rpm, and homogenize into the first solution;

[0070] Step A2, adding nanometer iron ferric oxide with a particle size of 300nm to the first solution several times in a small amount, then ultrasonically dispersed at 50KHz and 120W, and stirred continuously for 15 hours at a stirring speed of 800rpm to obtain a uniform first solution. Second solution, the concentration of nano ferric oxide in the second s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com