Production process for preparing stable cement raw material

A cement raw material and production process technology, applied in the field of cement processing, can solve problems such as incomplete dust removal by dust collectors, poor dust collection effects, and health effects on workers, so as to ensure filtration and ventilation effects, a good working environment, and guaranteed work environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A production process for making stable cement raw meal, comprising the following steps:

[0039] a. Crushing the raw materials through the crusher;

[0040] b. Collect the dust generated by the crusher through the dust collector;

[0041] c. Add lime with 2% cement raw meal content and 5% pure cement with cement raw meal raw material obtained by pulverizing with a crusher;

[0042] d. Add water and mix in a pre-humidifier;

[0043] e. Feed the water-added raw materials into the disc-type ball forming machine to make raw meal balls. The ball forming time is 100 seconds, and the particle size of the raw meal balls is 3mm;

[0044] f. Naturally preserve the raw material balls at room temperature for more than two days.

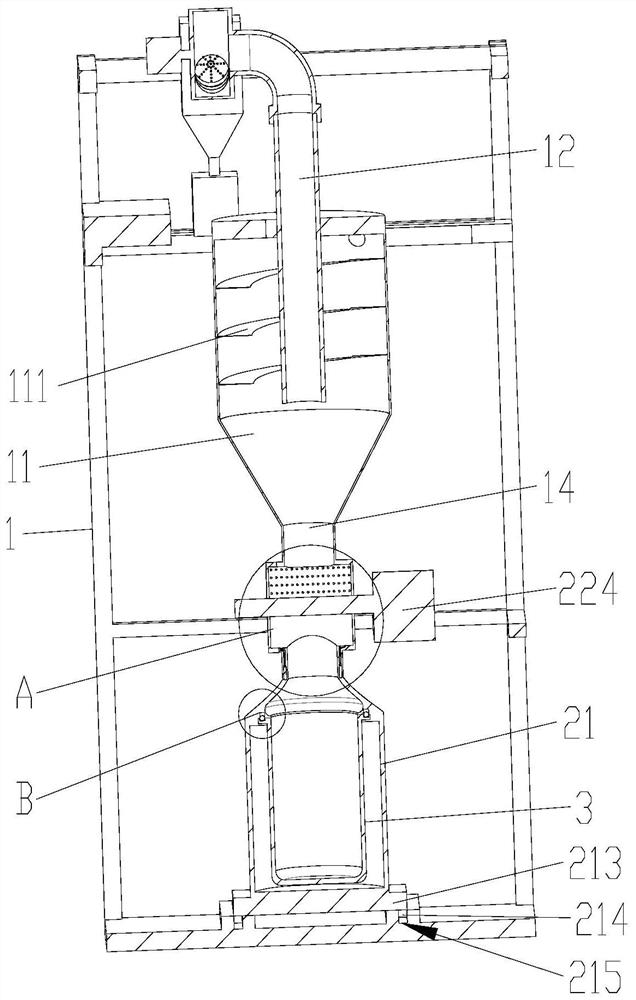

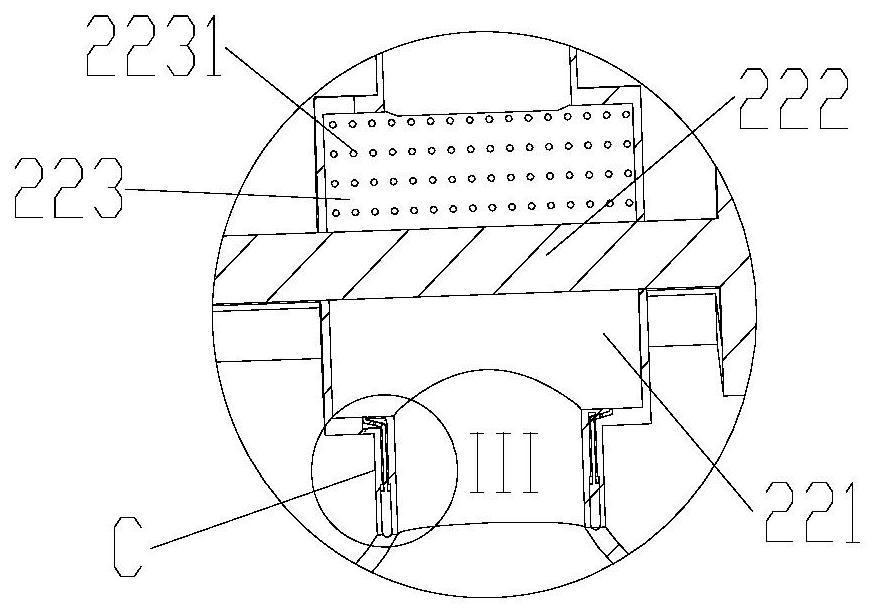

[0045] Such as Figure 1-7 As shown, the dust collector includes a frame 1, a main cylinder body 11, an air outlet pipe 12, an air inlet pipe 13, a dust outlet 14 and a dust collecting device. The main cylinder body 11 is welded on the frame 1, and the...

Embodiment 2

[0056] A production process for making stable cement raw meal, comprising the following steps:

[0057] a. Crushing the raw materials through the crusher;

[0058] b. Collect the dust generated by the crusher through the dust collector;

[0059] c. The raw materials obtained by pulverizing with a crusher plus lime with 3% cement raw meal and pure cement with 8% cement raw meal;

[0060] d. Add water and mix in a pre-humidifier;

[0061] e. Send the water-added raw materials into the disc-type ball forming machine to make raw meal balls. The ball forming time is 100 seconds, and the particle size of the raw meal balls is 5mm;

[0062] f. Naturally preserve the raw material balls at room temperature for more than two days.

Embodiment 3

[0064] A production process for making stable cement raw meal, comprising the following steps:

[0065] a. Crushing the raw materials through the crusher;

[0066] b. Collect the dust generated by the crusher through the dust collector;

[0067] c. Add lime with 4% cement raw meal amount and pure cement with 10% cement raw meal amount to the raw material obtained by pulverizing with a crusher;

[0068] d. Add water and mix in a pre-humidifier;

[0069] e. Send the water-added raw materials into the disc-type ball forming machine to make raw meal balls. The ball forming time is 100 seconds, and the particle size of the raw meal balls is 7mm;

[0070] f. Naturally preserve the raw material balls at room temperature for more than two days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com