Velvet ceramic rock plate and preparation method thereof

A velvet and slate technology, applied in the field of ceramics, can solve the problems of uncomfortable brightness, easy to hide dirt, unsanitary, etc., and achieve the effect of ensuring the function of moisture absorption and release, high compactness, anti-fouling, and hard texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

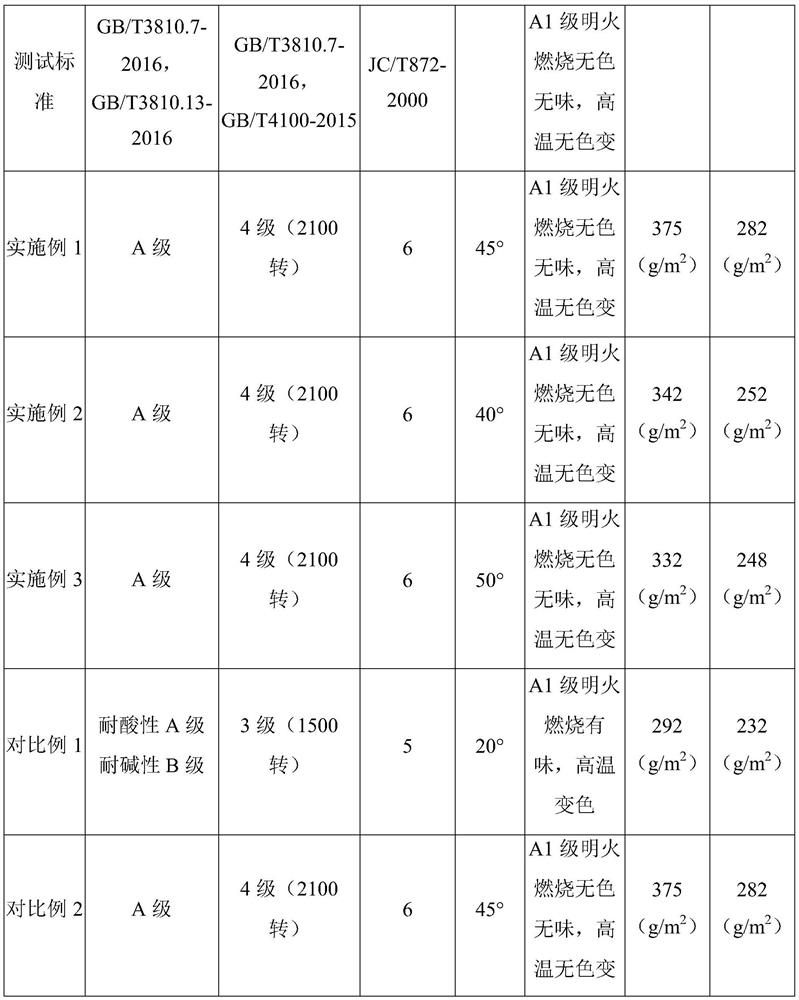

Examples

Embodiment 1

[0042] A velvet glaze, mainly composed of the following raw materials: potassium carbonate, quartz, calcite, feldspar, boric acid, talc, zircon sand, and nano-powders of metal oxides; the nano-powders of metal oxides are CdO, MnO, MgO, CaO, SrO, BaO, Li 2 O, Na 2 O, K 2 O, Rb 2 O, ZrO 2 、TiO 2 , ZnO, Al 2 o 3 .

[0043] In terms of mass percentage, the chemical composition of the above-mentioned velvet glaze includes: 13% Al 2 o 3 , 45% SiO 2 , 0.3% Fe 2 o 3 , 5% CaO, 6% MgO, 4% K 2 O, 2%Na 2 O, 0.3%TiO 2 , 0.05% Zr(Hf)O 2 , 0.05% B 2 o 3 , 2% BaO, 0.03% Li 2 O, 3.64% ZnO, 6% SrO, 0.01% MnO, 0.2% Rb 2 O, 0.01% ZrO 2 , 0.01% CdO, 0.1% P 2 o 5 , 0.1%F, 0.1%SO 3 ; The loss on ignition of the velvet glaze is 12%.

[0044] A preparation method of a velvet glaze, which comprises mixing quartz, calcite, feldspar, talc, and fluorite, ball milling, sieving, adding potassium carbonate and metal oxide nano-powders for mixing, and then adding boric acid to obtain t...

Embodiment 2

[0053] A velvet glaze, mainly composed of the following raw materials: potassium carbonate, quartz, calcite, feldspar, boric acid, talc, zircon sand, fluorite, nano powder of metal oxides; metal oxides are CdO, MnO, MgO , CaO, SrO, BaO, Li 2 O, Na 2 O, K 2 O, Rb 2 O, ZrO 2 、TiO 2 , ZnO, Al 2 o 3 .

[0054] In terms of mass percentage, the chemical composition of the above-mentioned velvet glaze includes: 13% loss on ignition, 15% Al 2 o 3 , 50% SiO 2 , 0.3% Fe 2 o 3 , 6% CaO, 8% MgO, 4% K 2 O, 2%Na 2 O, 0.3%TiO 2 , 0.05% Zr(Hf)O 2 , 0.05% B 2 o 3 , 2% BaO, 0.04% Li 2 O, 3.63% ZnO, 6% SrO, 0.01% MnO, 0.2% Rb 2 O, 0.2% ZrO 2 , 0.08% CdO, 0.1% P 2 o 5 , 0.08%F, 0.08%SO 3 .

[0055] A preparation method of a velvet glaze, which comprises mixing quartz, calcite, feldspar, talc, and fluorite, ball milling, sieving, adding potassium carbonate and metal oxide nano-powders for mixing, and then adding boric acid to obtain the velvet glaze .

[0056] A velvet ce...

Embodiment 3

[0064] A velvet glaze, mainly composed of the following raw materials: potassium carbonate, quartz, calcite, feldspar, boric acid, talc, zircon sand, fluorite, metal oxide nano powder; the metal oxide nano powder is CdO , MnO, MgO, CaO, SrO, BaO, Li 2 O, Na 2 O, K 2 O, Rb 2 O, ZrO 2 、TiO 2 , ZnO, Al 2 o 3 .

[0065] In terms of mass percentage, the chemical composition of the above-mentioned velvet glaze includes: 13% loss on ignition, 13% Al 2 o 3 , 42.27% SiO 2 , 0.3% Fe 2 o 3 , 6% CaO, 6% MgO, 3% K 2 O, 3%Na 2O, 0.5%TiO 2 , 0.08% Zr(Hf)O 2 , 0.08% B 2 o 3 , 3% BaO, 0.16% Li 2 O, 3% ZnO, 6% SrO, 0.08% MnO, 0.2% Rb 2 O, 0.2% ZrO 2 , 0.01% CdO, 0.1% P 2 o 5 , 0.01%F, 0.01%SO 3 .

[0066] A preparation method of a velvet glaze, which comprises mixing quartz, calcite, feldspar, talc, and fluorite, ball milling, sieving, adding potassium carbonate and metal oxide nano-powders for mixing, and then adding boric acid to obtain the velvet glaze .

[0067] A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com