Preparation method of TiO2/g-C3N4 composite photocatalyst and preparation method of hydrogen

A technology of g-c3n4 and composite light, applied in the field of chemistry, can solve the problems of limiting ZnO and low hydrogen efficiency, and achieve the effect of promoting fast separation, fast separation rate, and enhancing photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

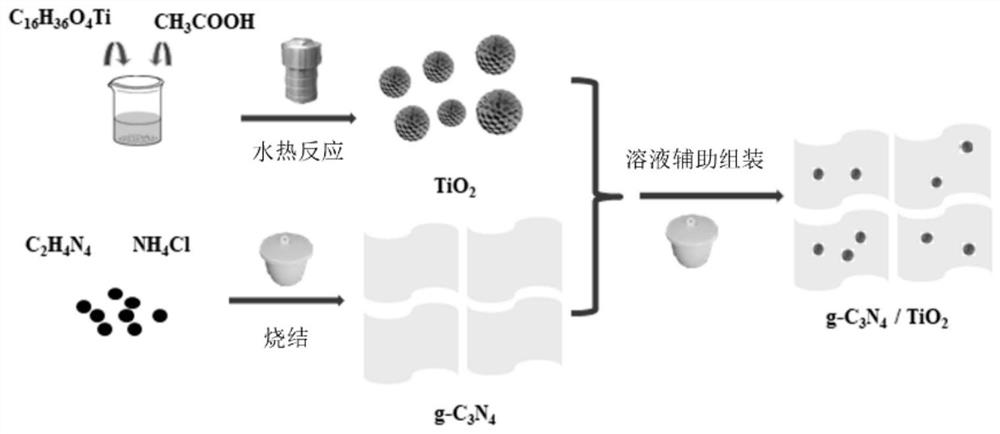

[0038] Specifically, the preparation method of graphite phase carbon nitride comprises the following steps:

[0039] Add tetrabutyl titanate into the acetic acid solution and stir, place the prepared solution in an autoclave and heat it in a high-temperature furnace to 120-160°C for 10-12 hours;

[0040] After the reaction is completed, the autoclave is naturally cooled to room temperature, the reaction product is obtained by centrifugation, the product is cleaned, and dried at 50-80° C. for at least 12 hours to obtain titanium dioxide.

[0041] Specifically, the preparation method of graphite phase carbon nitride comprises the following steps:

[0042] Mix and dissolve ammonium chloride and dicyandiamide according to the mass ratio of 3 to 7:1;

[0043] Heating the obtained solution at 80-120°C until a powdery substance is obtained;

[0044] The powdery material is sintered at 400-700° C. for at least 3 hours to obtain graphite phase carbon nitride.

[0045] Preferably, th...

Embodiment

[0051] 1. Preparation of TiO 2

[0052] Add 1ml of tetrabutyl titanate to 30ml of acetic acid to obtain solution A.

[0053] After the solution A was stirred vigorously for 10 minutes, the solution A was sealed in a Teflon autoclave with a volume of 50 ml, and the Teflon autoclave was placed in a high-temperature furnace, and the solution A was heated at 140° C. for 12 hours.

[0054] After the reaction was completed, the autoclave was naturally cooled to room temperature, and the reaction product B was obtained by centrifugation, and the reaction product B was carefully washed with water and absolute ethanol.

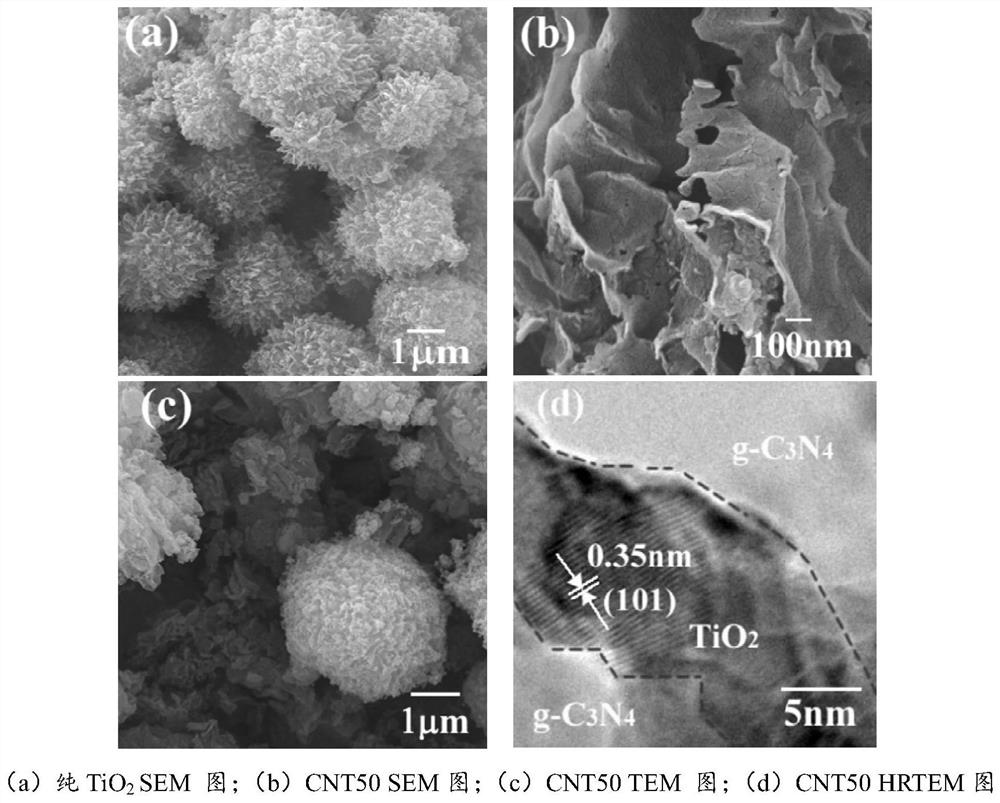

[0055] Dry the cleaned reactant B at 70 °C for 24 hours to obtain layered flower-like TiO 2 .

[0056] 2. Preparation of g-C 3 N 4 :

[0057] 10 g of ammonium chloride and 2 g of dicyandiamide were dissolved in 80 ml of deionized water and vigorously stirred for one hour to obtain solution C.

[0058] Solution C was dried at 100°C until substance D was obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice spacing | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com