A single-mode step-type polymer optical fiber and its preparation method

A polymer, step-type technology, used in cladding fibers, optical components, optical waveguides and light guides, etc., can solve problems such as increased propagation loss, unsatisfactory dispersion effect, etc., to achieve superior drawing performance, ensure interface bonding quality, Avoid the effect of increased loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

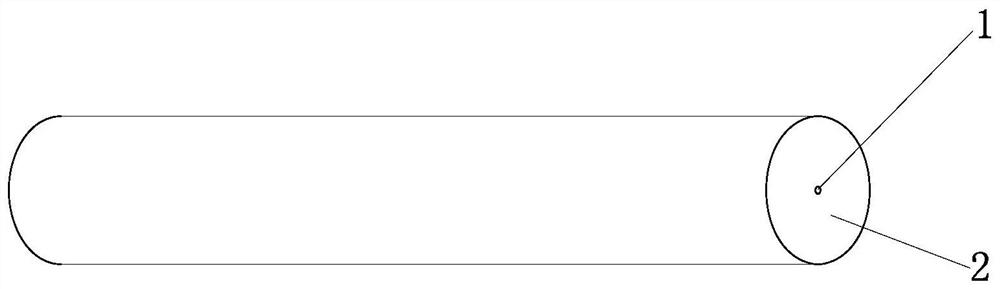

[0031] The invention provides a method for preparing a single-mode step-type polymer optical fiber, which comprises the following steps:

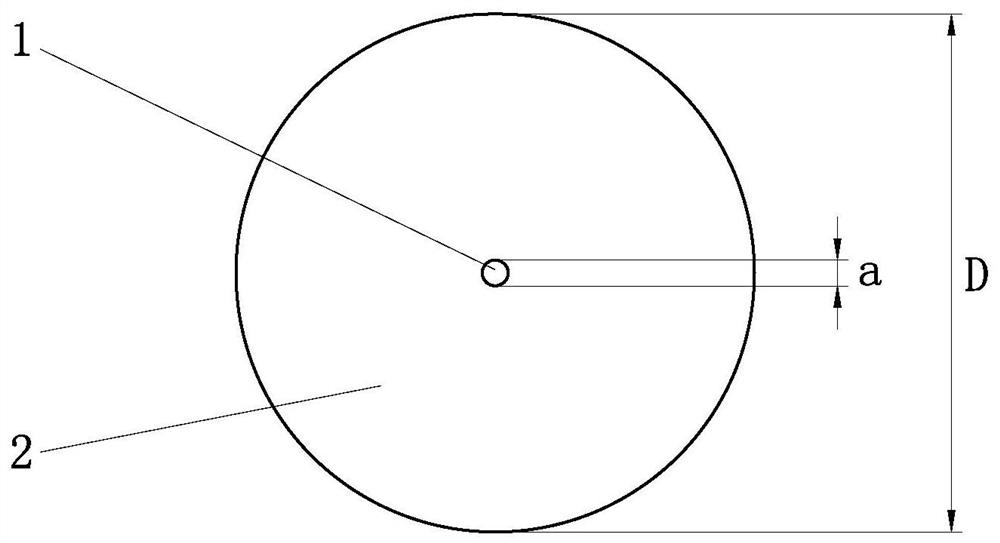

[0032] (1) Melt and extrude Zeonex E48R granules into a round rod through a precision extruder, and cool to room temperature 25°C. The diameter of the made round rod is 4.9mm; the melting temperature is controlled at 140-180°C.

[0033] (2) Melt and extrude Zeonex 480R granules into a cylinder through a precision extruder, and cool it to room temperature 25°C. The outer diameter of the produced cylinder is 125.5mm, and the inner diameter is 4.7mm; the melting temperature is controlled at 140-180 ℃.

[0034] (3) Grinding and polishing the outer surface of the round rod made in step (1) and the inner and outer surfaces of the cylinder made in step (2) respectively, so that the inner surface of the cylinder and the outer surface of the round rod have a size between Interference fit H7 / s6.

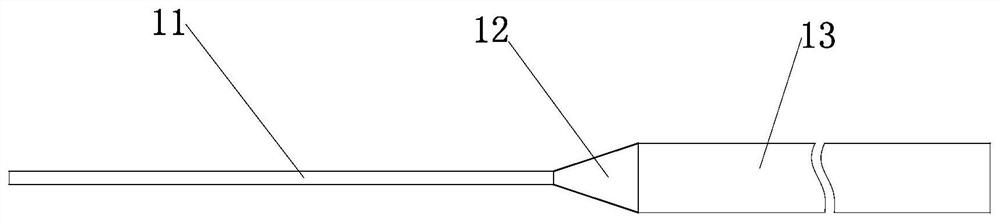

[0035] (4) drawing one end of the round rod obtaine...

Embodiment 2

[0041] The invention provides a method for preparing a single-mode step-type polymer optical fiber, which comprises the following steps:

[0042] (1) Melt and extrude Zeonex E48R granules into a round rod through a precision extruder, and cool to room temperature 25°C. The diameter of the made round rod is 4.5mm; the melting temperature is controlled at 140-180°C.

[0043] (2) Melt and extrude Zeonex 480R granules into a cylinder through a precision extruder, and cool to room temperature 25°C. The outer diameter of the produced cylinder is 125.6mm, and the inner diameter is 4.3mm; the melting temperature is controlled at 140-180 ℃.

[0044] The contents of steps (3) to (7) are the same as the contents of steps (3) to (7) in Embodiment 1, and will not be repeated here.

[0045] (8) The optical fiber preform obtained in step (7) is finally drawn by an optical fiber drawing machine, and finally drawn into a single-mode optical fiber. The outer diameter of the single-mode optical...

Embodiment 3

[0047] The invention provides a method for preparing a single-mode step-type polymer optical fiber, which comprises the following steps:

[0048] (1) Melt and extrude Zeonex E48R granules into a round rod through a precision extruder, and cool to room temperature 25°C. The diameter of the made round rod is 4.6mm; the melting temperature is controlled at 140-180°C.

[0049] (2) Melt and extrude Zeonex 480R particles into a cylinder through a precision extruder, and cool to room temperature 25°C. The outer diameter of the produced cylinder is 125.8mm, and the inner diameter is 4.4mm; the melting temperature is controlled at 140-180 ℃.

[0050] The contents of steps (3) to (7) are the same as the contents of steps (3) to (7) in Embodiment 1, and will not be repeated here.

[0051] (8) The optical fiber preform obtained in step (7) is finally drawn by an optical fiber drawing machine, and finally drawn into a single-mode optical fiber. The outer diameter of the single-mode optica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com