Feedback type soil heavy metal real-time monitor

A real-time monitor and real-time monitoring technology, applied in sampling devices and other directions, can solve problems such as inability to accurately reflect the actual effect of soil, complex ground geological conditions, and inability to open the drill tip and blade, so as to improve accuracy and data reliability, improve Monitoring efficiency, effect of reducing rotational torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

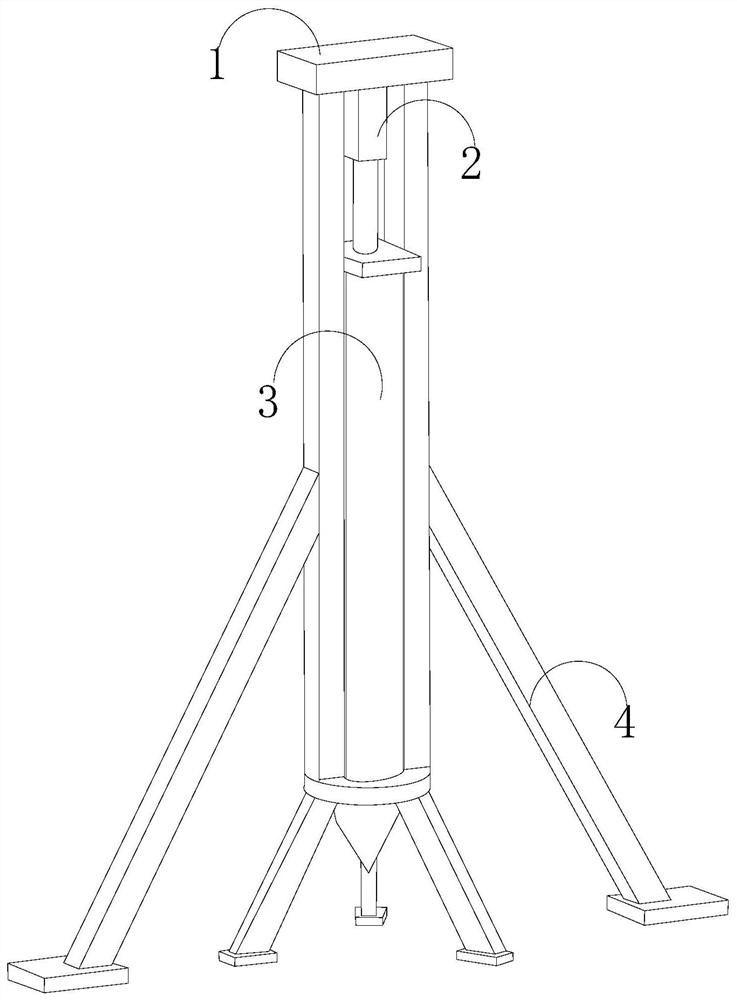

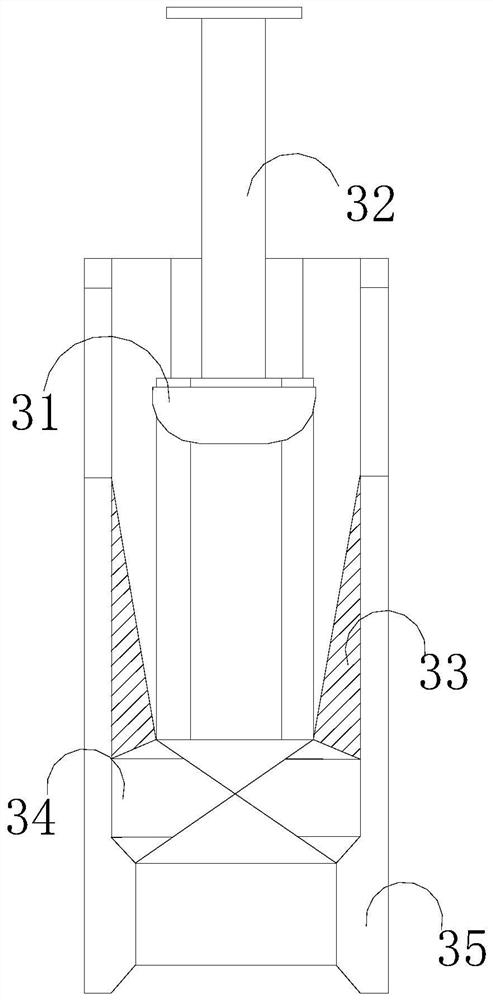

[0030] like Figure 1-Figure 4As shown, the present invention provides a feedback type soil heavy metal real-time monitor, and its structure includes a real-time monitoring board 1, a lifting driver 2, a drilling tool 3, and a support foot 4. The real-time monitoring board 1 and the lifting driver 2 are electrically connected One end of the drilling tool 3 located inside the real-time monitoring board 1 is hingedly connected with the lifting driver 2, and the bottom of the drilling tool 3 is provided with a support foot 4 with the same size and structure. The drilling tool 3 includes a stress block 31, a stress rod 32. Tension net 33, reaming structure 34, track 35, the stress block 31 is fixedly connected to one side of the stress bar 32, the other side of the stress bar 32 is inserted into the interior of the lifting driver 2, and the inner wall of the track 35 is fixed A tension net 33 is installed, and the bottom of the tension net 33 is embedded around the periphery of th...

Embodiment 2

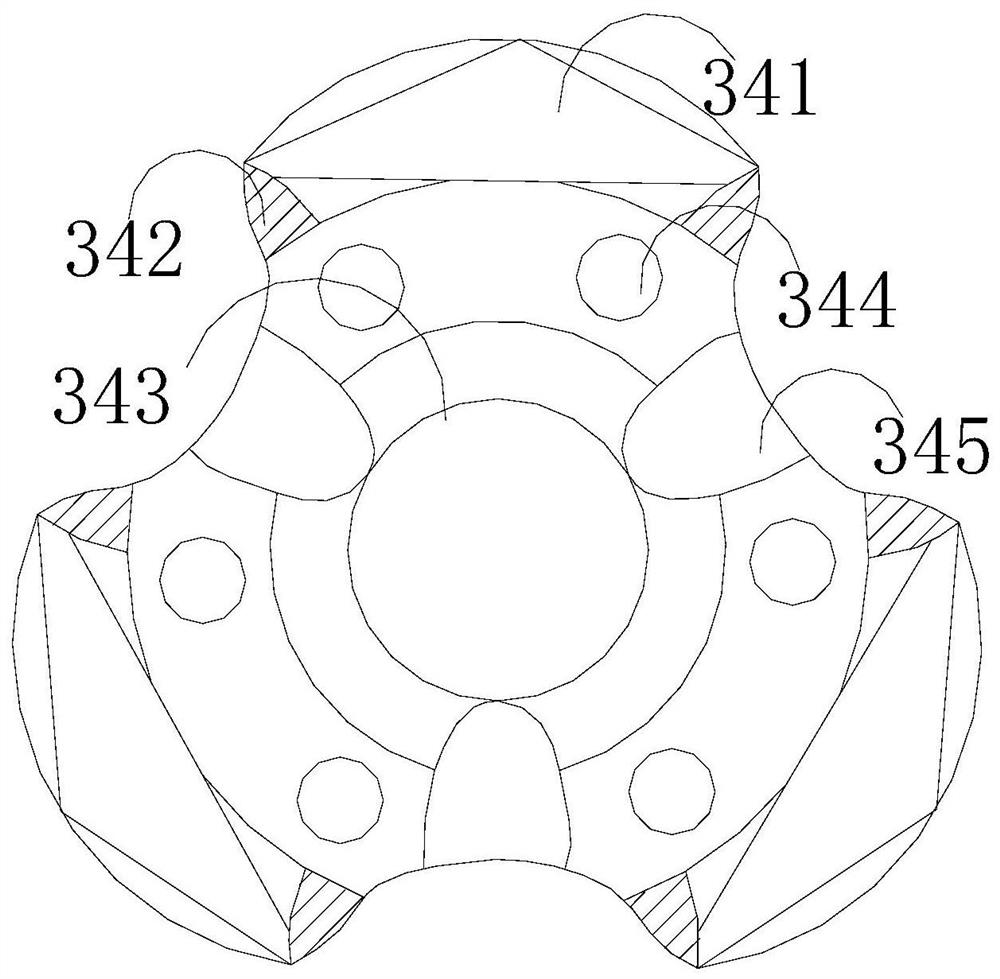

[0032] like Figure 5-Figure 7 As shown, on the basis of Embodiment 1, the present invention combines the mutual cooperation of the following structural components. The advancing structure 342 includes a support ring 421, a fixed point groove 422, a roller part 423, a fitting rolling ball 424, a pressing plate 425, The anti-deflection device 426, the fixed-point grooves 422 are distributed symmetrically along the outer circumference of the support ring 421, and the roller part 423 is embedded in the groove-shaped position, and the through hole on the arc-shaped surface of the roller part 423 is equidistantly movable. A fitting rolling ball 424, the pressing plate 425 and the anti-deflection device 426 are an integrated structure, the anti-deflection device 426 is against the surface of the inclined plate of the auxiliary expansion block 412, and the anti-deflection device 426 includes a clamping device 261 , buckle the capsule body 262, connect the top block 263, and the butt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com