Compressor oil return device, air conditioning system and oil return control method

An air-conditioning system and compressor technology, which is applied in compressors, refrigerators, refrigeration components, etc., can solve the problems of difficult oil return of lubricating oil and high oil discharge rate of compression cylinders, so as to meet the requirements of oil return, prevent gas leakage, and improve service life. The effect of longevity and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

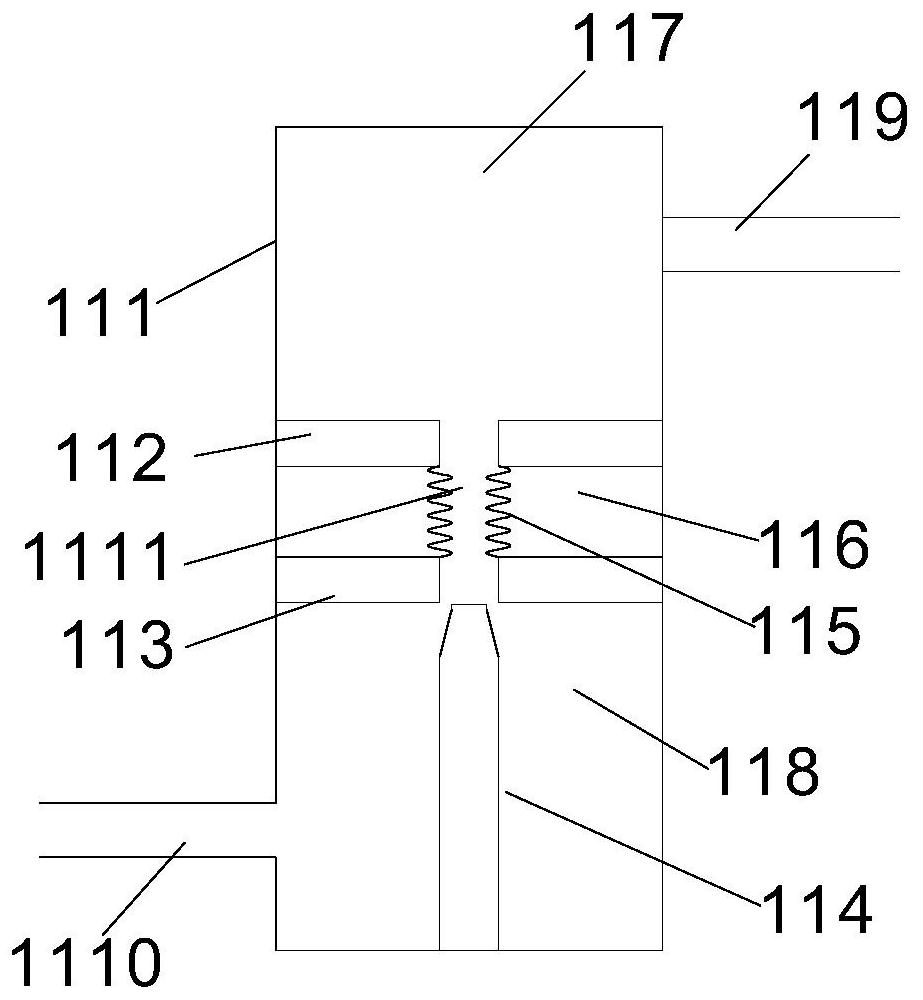

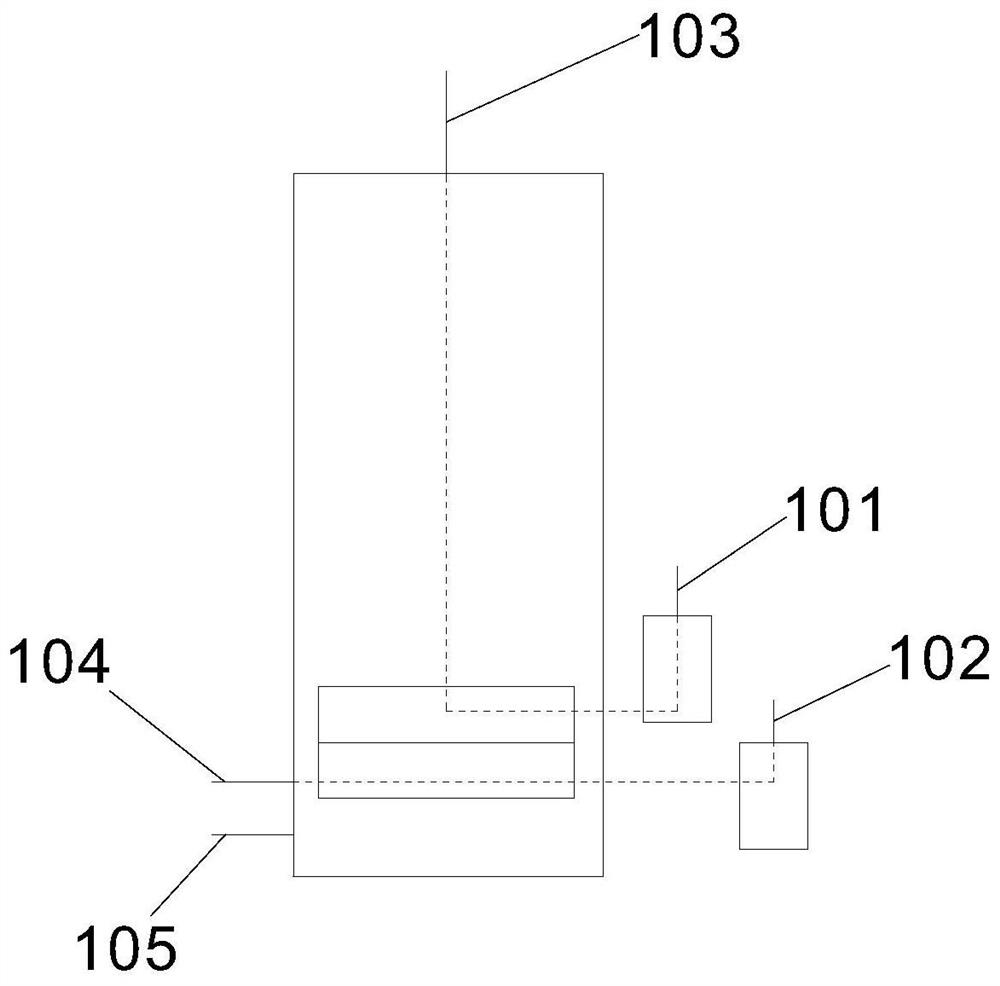

[0041] Such as Figure 1-2 As shown, in this embodiment, the present invention provides a compressor oil return device, including: a double-suction double-row compressor 1, an oil separator 12 connected to the double-suction double-row compressor 1, and an oil return assembly, wherein , the oil return assembly includes an oil return valve 11 and a connecting pipe. The oil return valve 11 has open conduction (the diameter is the same as the connecting pipe, and the resistance is small, and is suitable for the cooling operation mode of the dual-temperature system) and closed throttling (the diameter is smaller than The connecting pipe has a large resistance and is suitable for two states of the dual-temperature system (heating operation mode). The determination of the diameter of the oil return valve 11 when it is closed needs to meet the normal oil return under different exhaust pressure differences, and also to prevent cross-gas between the two exhaust gases.

[0042] In this...

Embodiment 2

[0047] Such as Figure 3-5 As shown, in this embodiment, the present invention provides an air conditioning system, including a compressor oil return device, an outdoor heat exchanger 4, a first indoor heat exchanger 8 and a second indoor heat exchanger 9, double suction and double row The compressor 1 is respectively connected with the first four-way valve 2 and the second four-way valve 3 through pipelines, the oil separator 12 is connected with the second four-way valve 3, and the first four-way valve 2 is connected with the first indoor heat exchange valve respectively. 8 and the outdoor heat exchanger 4, the second four-way valve 3 is connected with the outdoor heat exchanger 4 and the second indoor heat exchanger 9 respectively, and the outdoor heat exchanger 4 is respectively connected with the first indoor heat exchanger 8 and the second indoor heat exchanger 9 through pipelines. The second indoor heat exchanger 9 is connected; the first indoor heat exchanger 8 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com