Equipment and method for semi-continuously preparing high-purity magnesium with different purity degrees

A high-purity, semi-continuous technology, applied in the direction of improving process efficiency, can solve the problems of complex preparation process of high-purity magnesium, inability to realize continuous production, unsatisfactory magnesium purity, etc., and achieve simple structure, convenient operation, and avoid complex structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

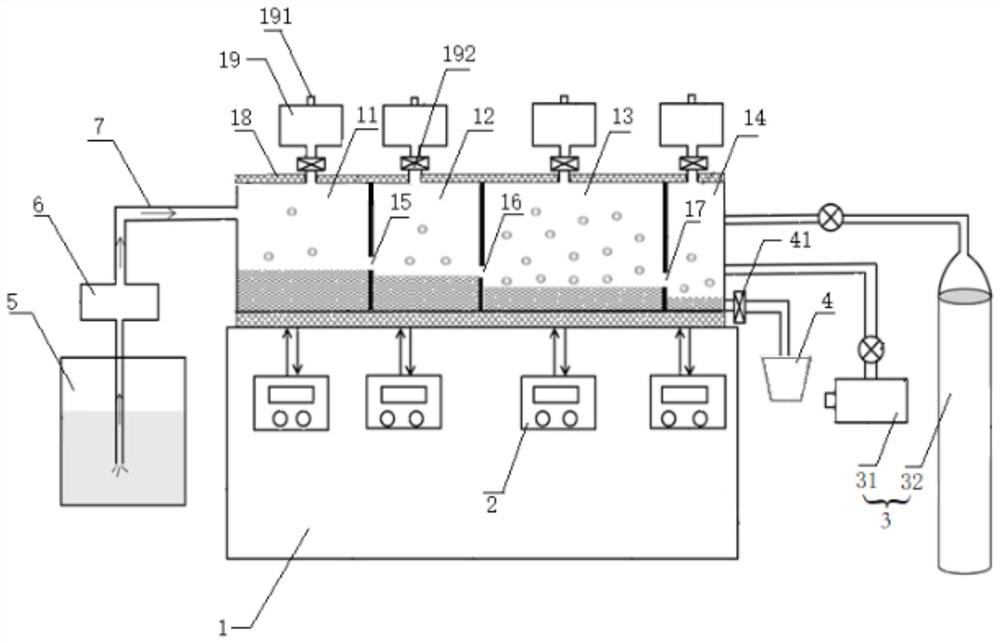

[0055] The pressure values in the four reaction chambers are controlled at 600Pa, and the temperature values in the No. 1 reaction chamber 11, No. 2 reaction chamber 12, No. 3 reaction chamber 13 and No. 4 reaction chamber 14 are controlled at 660°C, 680°C, and 750°C respectively and 770°C;

[0056] Step 2: After the solid magnesium is melted in the melting pot 5, it is transported to the intermediate pot 6, and then the liquid magnesium in the intermediate pot 6 is siphoned into the No. 1 reaction chamber 11 through the feeding pipeline 7;

[0057] Step 3: Liquid magnesium flows from No. 1 reaction chamber 11 into No. 2 reaction chamber 12, No. 3 reaction chamber 13 and No. 4 reaction chamber 14, liquid magnesium and low-boiling impurities in No. 1 reaction chamber 11 and No. 2 reaction chamber 12 Volatilize to the condenser 19 above, the liquid magnesium in the No. 3 storehouse volatilizes to the condenser 19 above, and the liquid magnesium in the No. 4 reaction chamber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap