A method for reducing the viscosity of polycarbosilane to improve the density of carbon/ceramic composites

A technology of ceramic composite materials and polycarbosilane, which is applied in the field of carbon/ceramic composite materials, can solve the problems of high toxicity of external organic solvents, performance defects of carbon/ceramic materials, and slow curing of PCS, so as to improve impregnation effect and impregnation efficiency , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

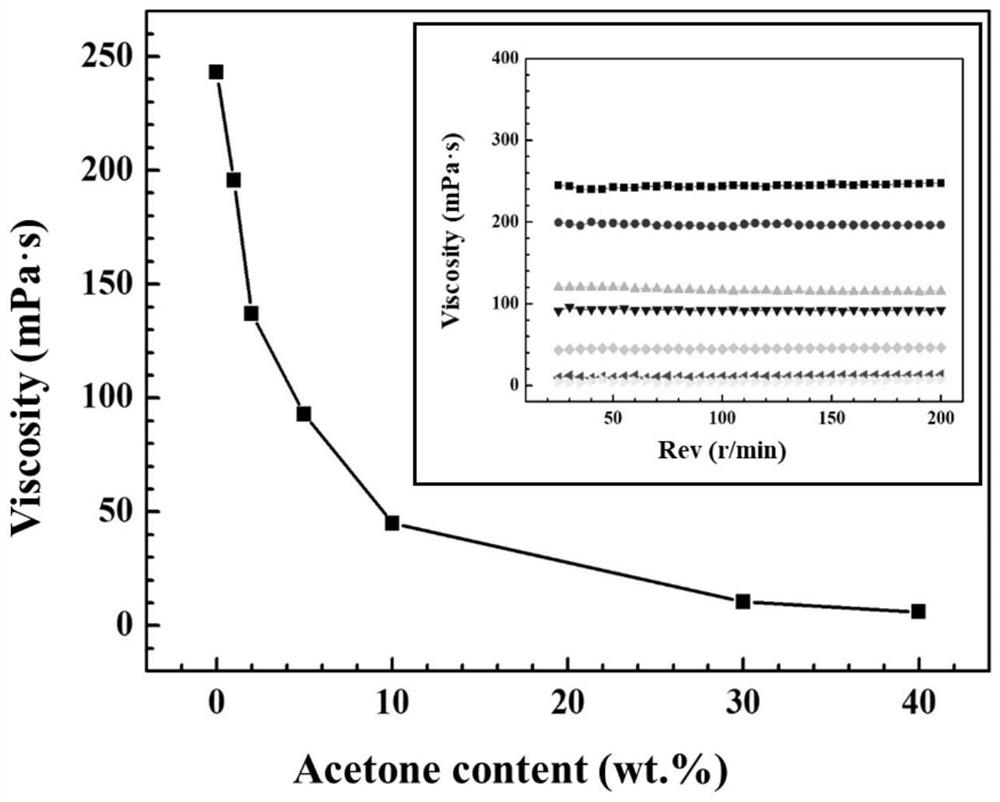

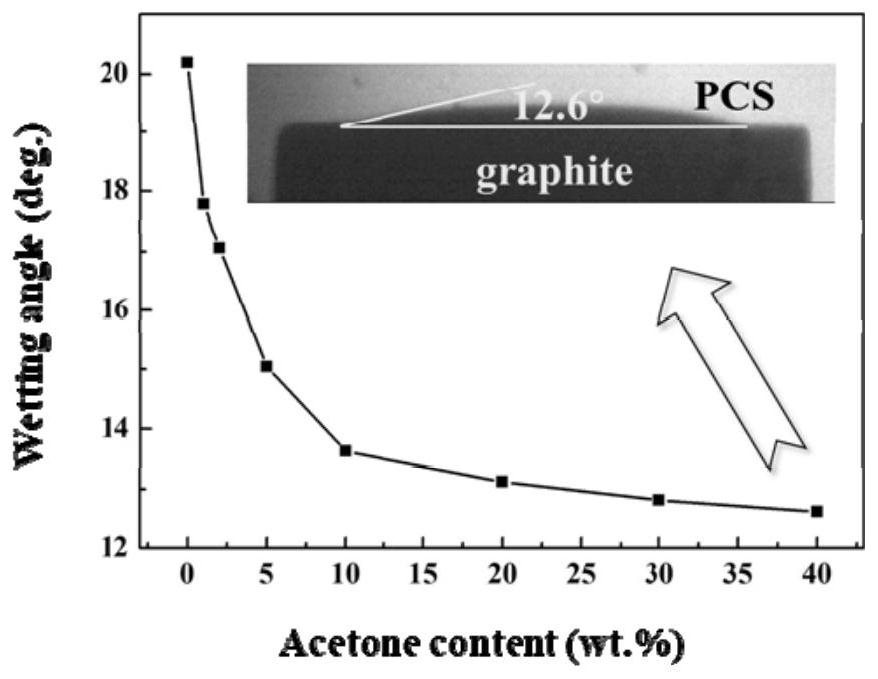

[0033] Embodiment 1: A method of reducing the viscosity of polycarbosilane in this embodiment to increase the density of carbon / ceramic composite materials. The method is specifically completed according to the following steps:

[0034] 1. Weighing: Measure the acetone and curing agent and place them in a beaker;

[0035] 2. Prepare a uniform mixed solution: fully stir the acetone, curing agent and polycarbosilane precursor to obtain a uniformly mixed polycarbosilane-acetone mixed solution;

[0036] 3. Impregnation of polycarbosilane-acetone mixed solution: immerse the mixed solution in the previous step into the block to be soaked;

[0037] 4. Volatile acetone: volatilize the acetone in the block by heating;

[0038] 5. Put the polycarbosilane after the acetone has completely volatilized in a vacuum blast drying oven at 180-200°C for 1-2 hours;

[0039] 6. Place the fully cured sample in a tube furnace, and crack it in an argon atmosphere with a gas flow rate of 10mL / min, a...

specific Embodiment approach 2

[0048] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the content of acetone in step 1 is 1wt.%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0049] Embodiment 3: This embodiment is different from Embodiment 1 in that the content of acetone in step 1 is 2wt.%. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com