Exterior wall texture thermal insulation coating material and preparation method thereof

A technology of thermal insulation coating and texture, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of unsatisfactory reflective heat insulation effect, high density of coating layer, layered segregation, etc., and achieve effective Good for environmental protection, low thermal conductivity, low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

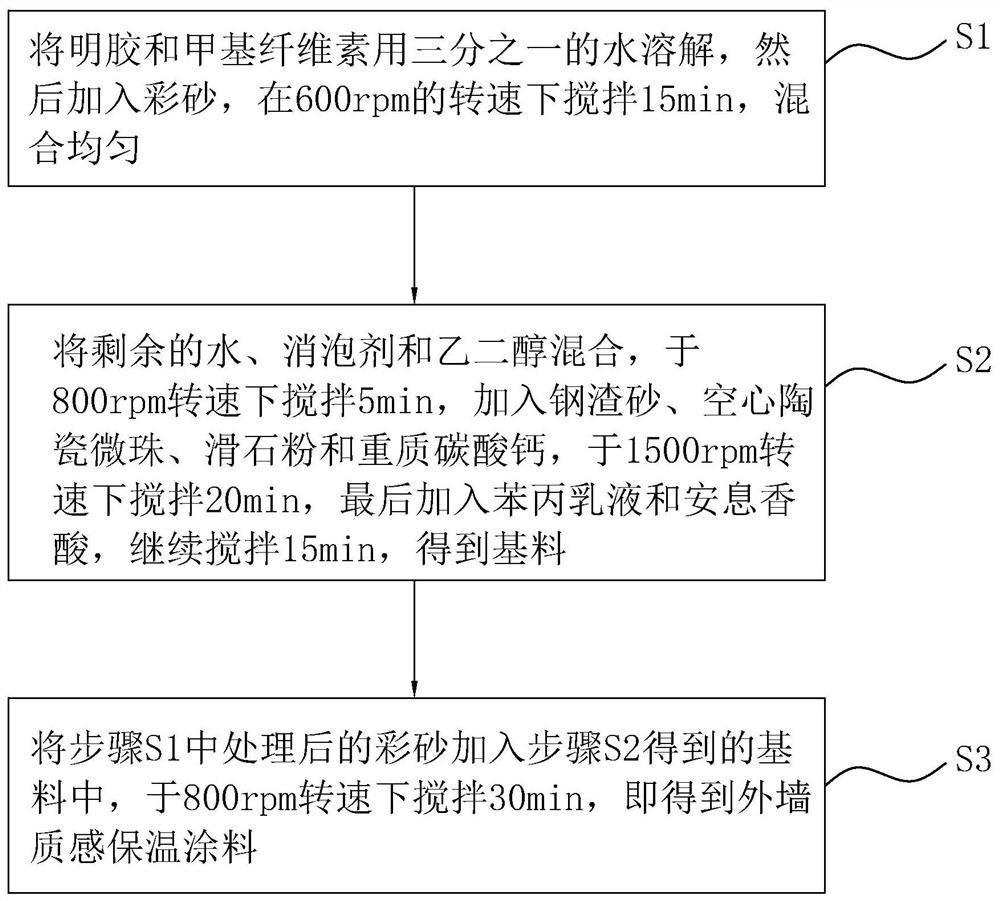

[0049] Embodiment 1: A kind of external wall texture thermal insulation coating, each component and its corresponding parts by weight are as shown in Table 1, refer to figure 1 , and obtained by the following steps:

[0050] S1, dissolve gelatin and methylcellulose with one-third of water, then add colored sand, stir at 600rpm for 15min, and mix well;

[0051] S2, mix the remaining water, defoamer and ethylene glycol, stir at 800rpm for 5min, add steel slag sand, hollow ceramic microspheres, talcum powder and heavy calcium carbonate, stir at 1500rpm for 20min, and finally add benzene Acrylic emulsion and benzoic acid, continue to stir 15min, obtain base material;

[0052] S3, add the colored sand treated in step S1 to the base material obtained in step S2, and stir at 800 rpm for 30 minutes to obtain the thermal insulation coating with exterior wall texture.

Embodiment 2-6

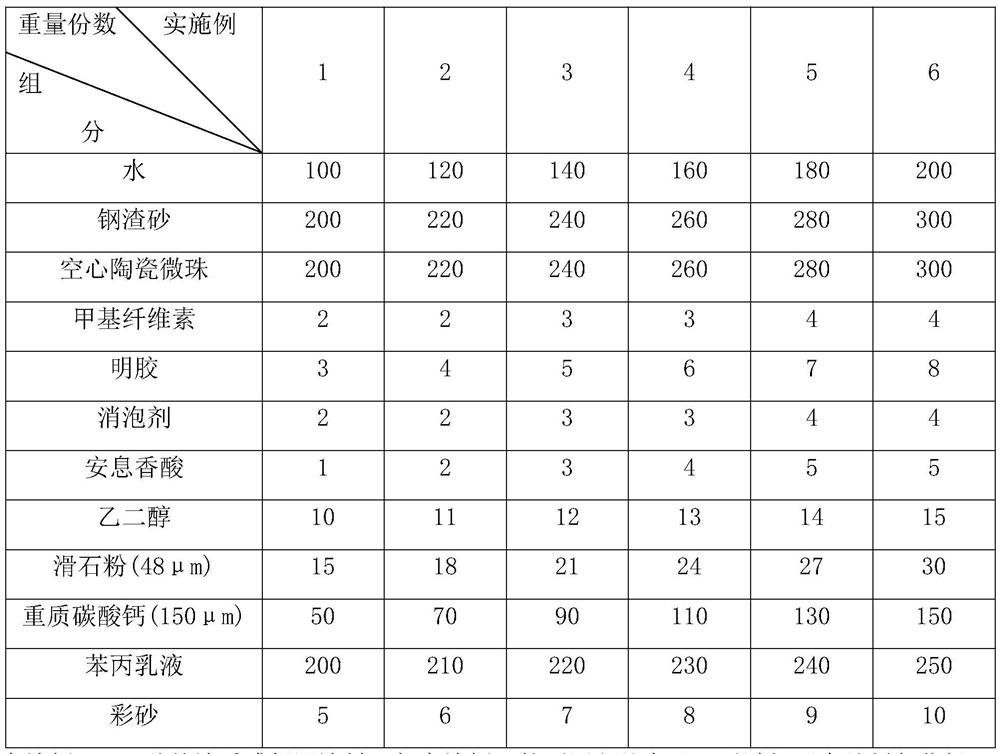

[0053] Example 2-6: A textured thermal insulation coating for exterior walls. The difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0054] Each component and parts by weight thereof in Table 1 Embodiment 1-6

[0055]

Embodiment 7

[0056] Embodiment 7: An exterior wall texture thermal insulation coating, which differs from Embodiment 1 in that it is prepared through the following steps:

[0057] S1, dissolve gelatin and methylcellulose with one-third of water, then add colored sand, stir at 700rpm for 10min, and mix well;

[0058] S2, mix the remaining water, defoamer and ethylene glycol, stir at 1000rpm for 4min, add steel slag sand, hollow ceramic microspheres, talcum powder and heavy calcium carbonate, stir at 1200rpm for 25min, and finally add benzene Acrylic emulsion and benzoic acid, continue to stir 18min, obtain base material;

[0059]S3, add the colored sand treated in step S1 to the base material obtained in step S2, and stir at 1000 rpm for 25 minutes to obtain the exterior wall texture thermal insulation coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com