Stamping die for needle-shaped electrode, plasma needle-shaped electrode and preparation method of plasma needle-shaped electrode

A punching die and needle electrode technology, applied in the field of plasma needle electrode and its preparation, and needle electrode punching die field, can solve the problems of environmental pollution, high processing cost, long labor time, etc., reduce production cost, The effect of improving sterilization efficiency and protecting the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

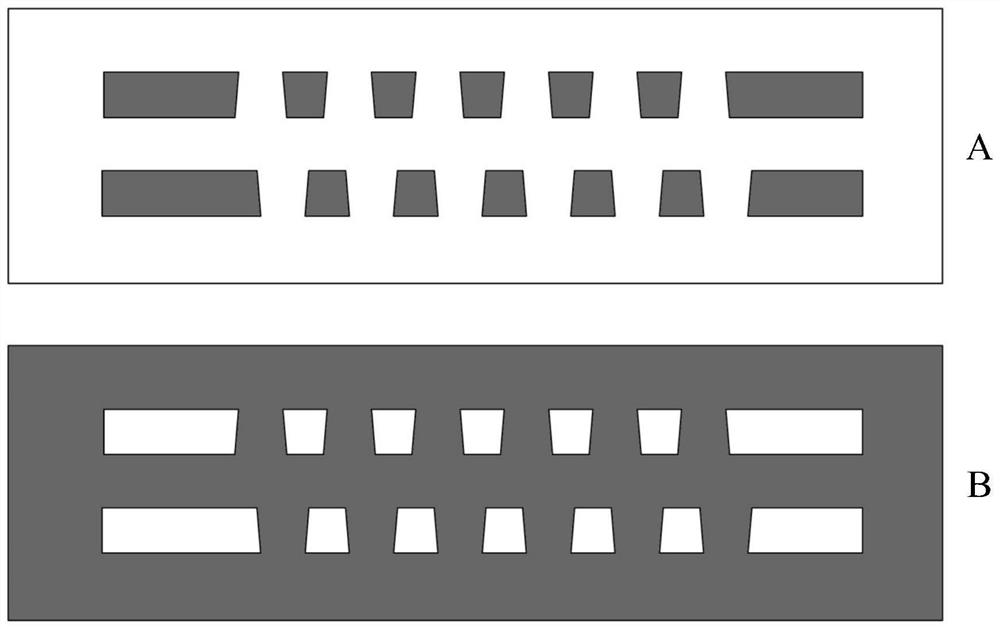

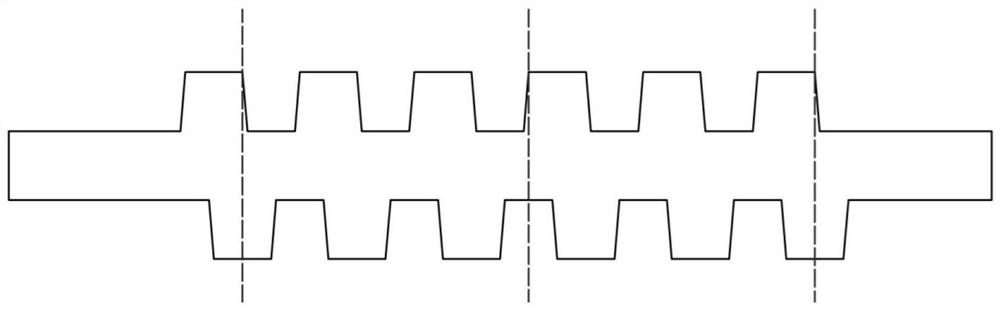

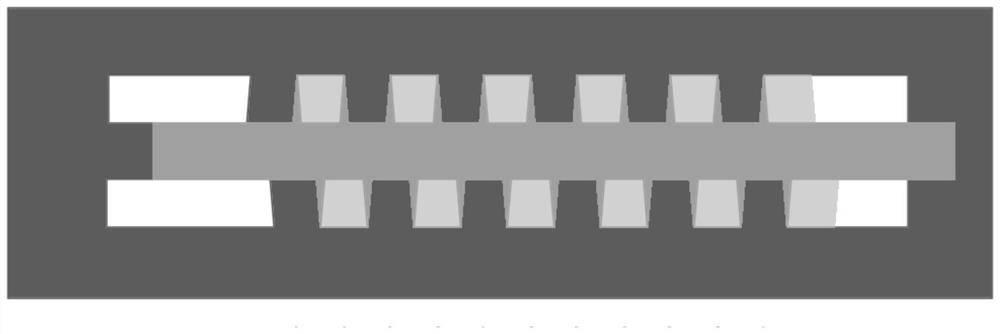

[0031] The stamping die of the needle electrode in this embodiment is as follows: figure 1 shown, including a tightly bonded die and punch ( figure 1 In the middle A is a punch, B is a concave, and the shaded part represents a protrusion, and the blank part represents a depression), and two groups of isosceles trapezoidal protrusions with parallel bases and opposite upper bases are arranged on the punch. The size and shape of the lumbar trapezoidal protrusions are consistent, and the spacing between adjacent isosceles trapezoidal protrusions is consistent; the corresponding positions on the concave mold are provided with depressions that have the same shape as the convex molds.

[0032] In this embodiment, the distance between the upper bases of adjacent isosceles trapezoidal protrusions on the punch is equal to the length of the upper bases of the isosceles trapezoidal protrusions.

[0033] In this embodiment, the length of the upper base of the isosceles trapezoidal protrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com