Stamping equipment

A technology of stamping equipment and equipment, used in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of insufficient stamping, inability to judge stamping parts in place, and difficult to judge materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

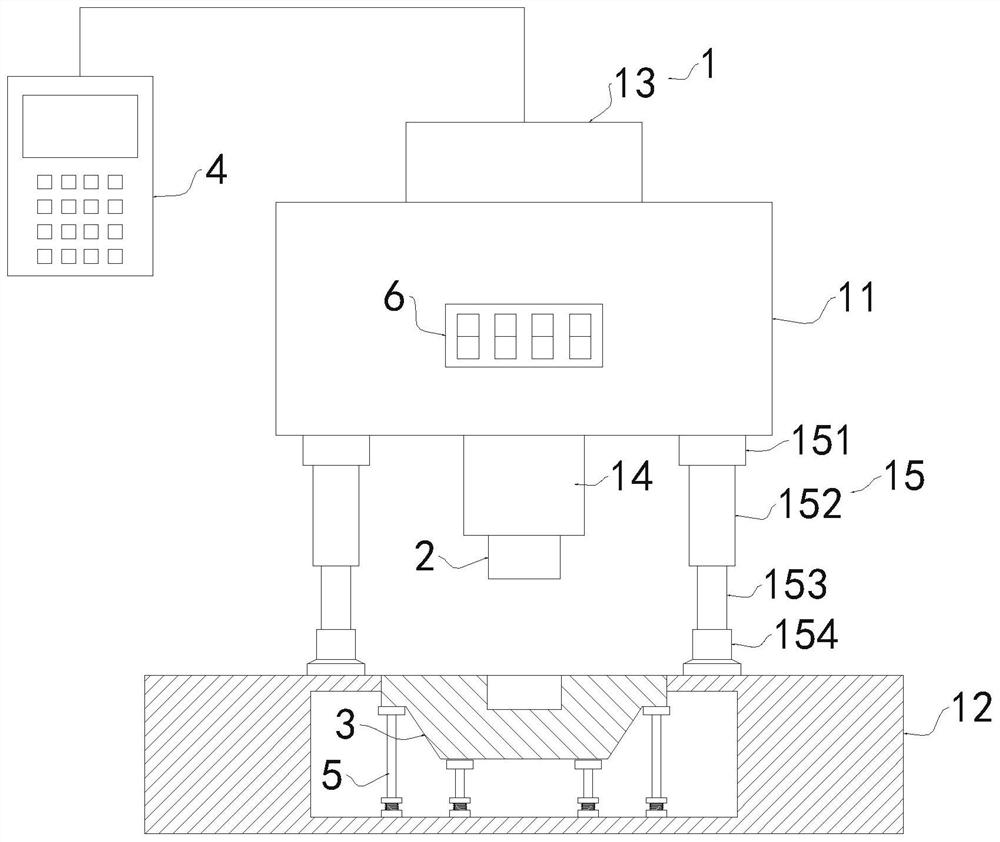

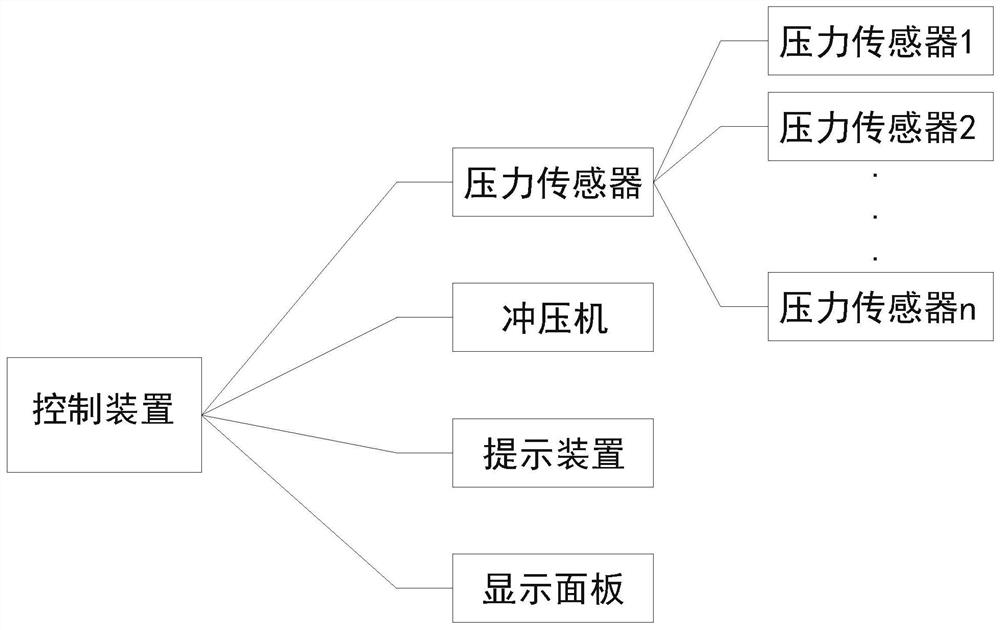

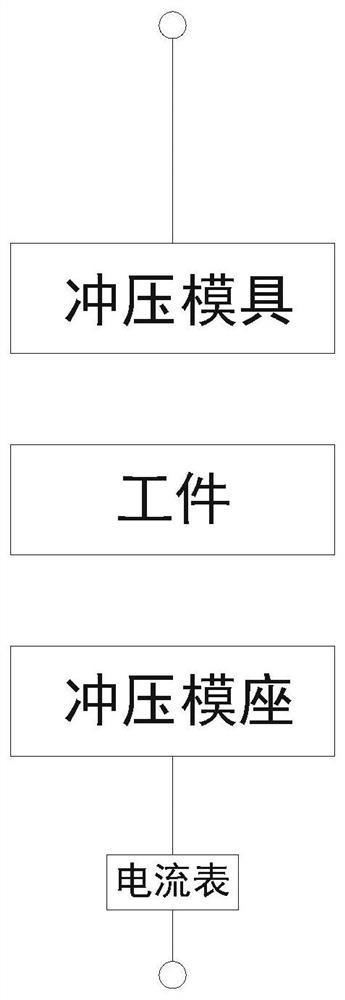

[0037] see Figure 1-4 , a stamping equipment, including equipment body 1, stamping die 2, stamping die base 3 and computer control device 4; stamping die 2 and stamping die base 3 are installed on the equipment body 1, and distributed up and down; computer control device 4 and The device body 1 is connected to control the stamping die 2 to move down and stamp the workpiece placed on the stamping die base 3; more than one pressure sensor 5 is arranged at the bottom of the stamping die base 3, and the number of more than one pressure sensor 5 forms a shape that matches the mold , the upper end surface of the pressure sensor 5 is in contact with the outer surface of the stamping die base 3; the pressure sensor 5 is connected with the computer control device 4, and the computer control device 4 is preset with a pressure qualified range; when the stamping die 2 is controlled by the computer control device 4 to punch When the workpiece in the die base 3 is stamped, the pressure sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com