Forming and correcting manufacturing method for aluminum alloy vehicle head skin of urban railway vehicle

A manufacturing method and technology of aluminum alloy, applied in railway transportation, railway transportation, climate sustainability, etc., can solve the problems of wrinkles and cracks, difficulty in forming and correction, and inability to meet production needs, so as to reduce the scrap rate and improve the design. The effect of line accuracy and shortening of auxiliary time for scribing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

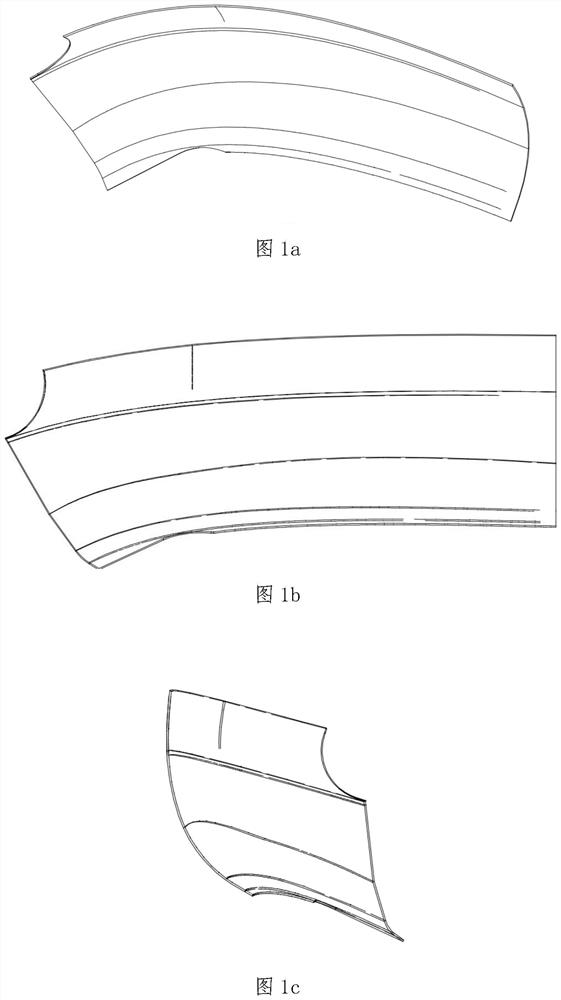

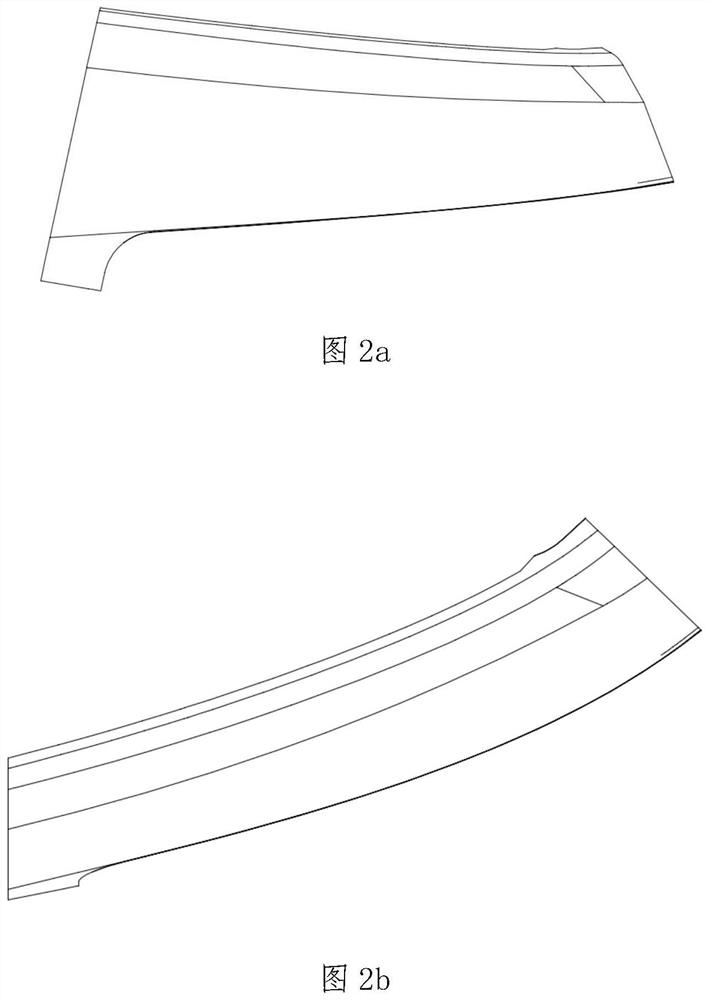

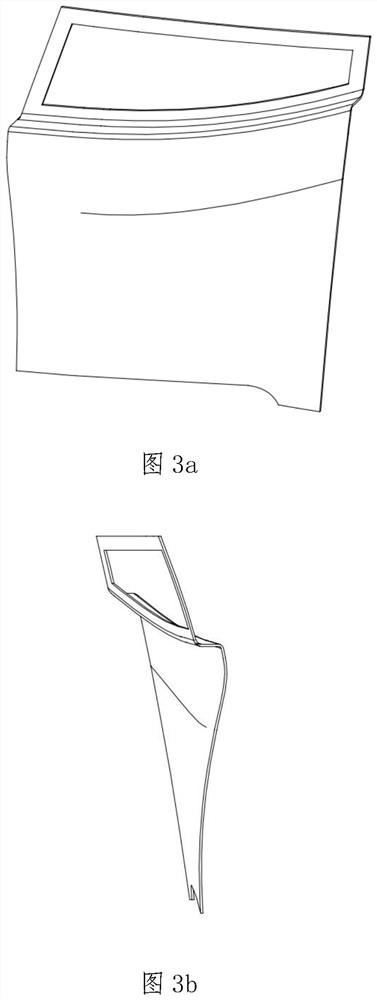

[0026] Specific embodiment two, combine Figure 1 to Figure 6 Describe the implementation mode. This implementation mode is an example of the manufacturing method for forming and correcting the aluminum alloy headboard skin of the city railway vehicle described in the first specific embodiment mode: the method is realized by the following steps:

[0027] The first step: draw

[0028] After calendering, there is a machining allowance on the periphery of the skin. At this time, the skin is larger than the trimmed membrane. The skin is buckled on the trimmed membrane, and the first line is drawn. The skin is in the original shape of the trimmed membrane. There is a machining allowance of 30mm on the line. After using manual plasma to cut off excess auxiliary materials, the skin will spring back and deform.

[0029] Step two: choose

[0030] According to the difference in deformation of each cut edge structure of the skin, select a suitable vibrating hammer forming mold to dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com