Composite coating as well as preparation method and application thereof

A composite coating and coating layer technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of harsh working environment, disappearance, decline, etc., to improve neutral salt spray resistance, good durability The effect of corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

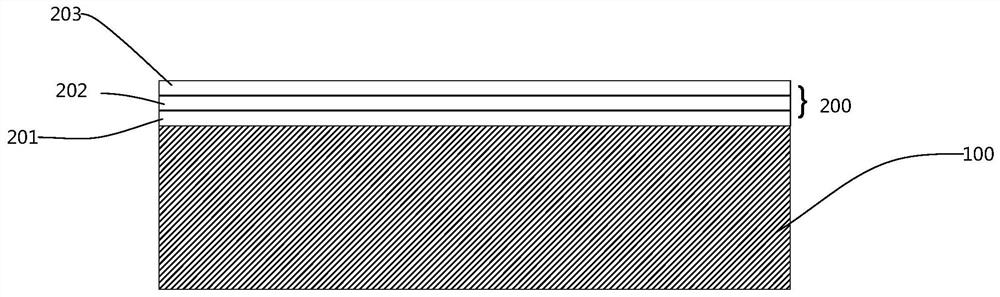

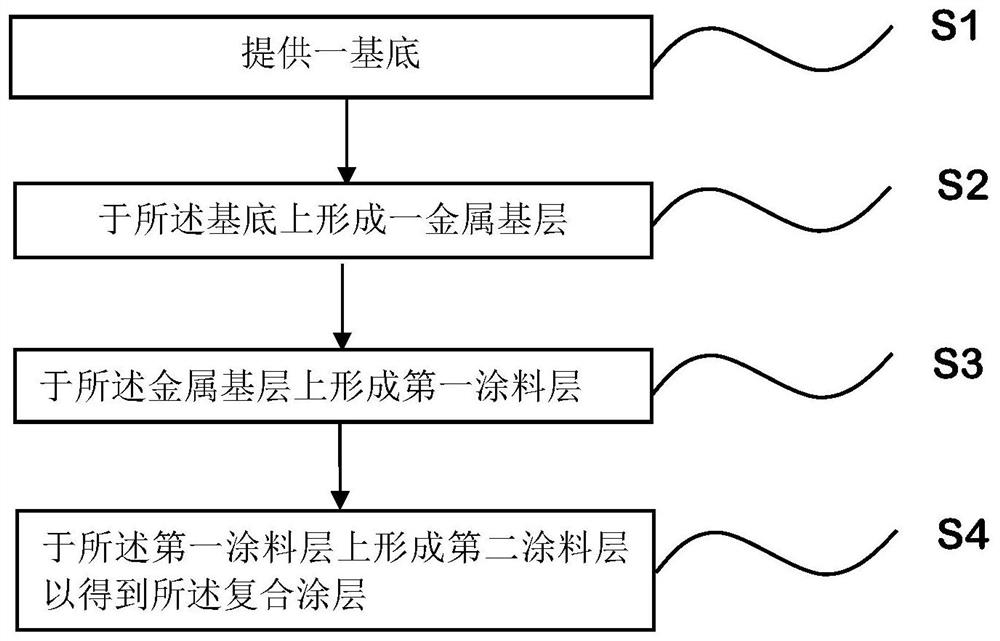

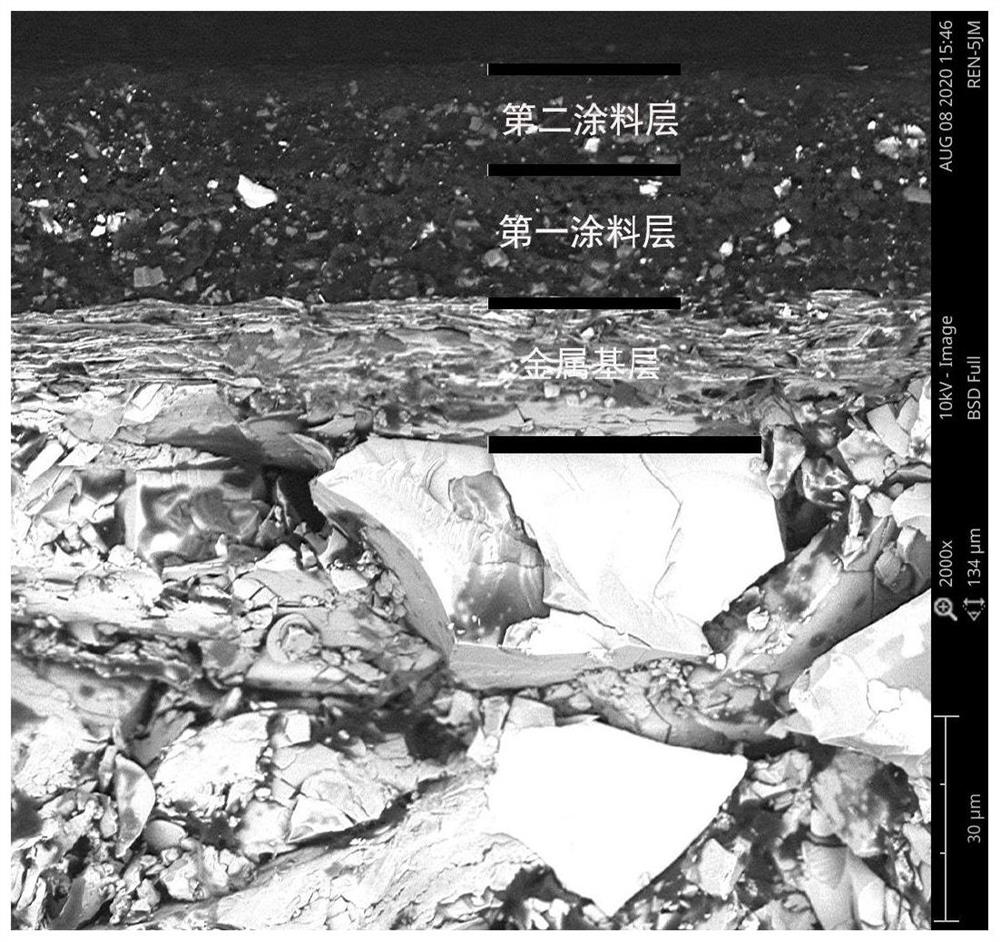

[0030] see Figure 1 to Figure 3 . Another aspect of the present invention also provides a method for preparing the composite coating as described above, the method at least including the steps of S1-S4:

[0031] S1: providing a base;

[0032] S2: forming a metal base layer on the substrate;

[0033] S3: forming a first paint layer on the metal base layer;

[0034] S4: forming a second paint layer on the first paint layer to obtain the composite coating;

[0035] Wherein, the metal base layer includes one or more combinations of zinc, aluminum, and nickel; the first paint layer includes a substance composed of nanoparticles, epoxy resin, and amino resin, and the second paint layer includes a ring Oxygen resins, polyurethane resins, novolak resins or aldehyde and ketone resins are composed of one or more combinations.

[0036] In step S1, the substrate 100 can be metal products such as NdFeB magnets, and the substrate 100 can also be pretreated before forming the composite c...

Embodiment 1

[0045] (1) Chamfer grinding: The surface of the bonded NdFeB magnet is polished by mechanical vibration grinding and rolling chamfering, and the final magnet size is: outer diameter 22mm×inner diameter 19.7mm×thickness 12.3mm.

[0046] (2) Ultrasonic cleaning: Put the chamfered and polished magnet into an ultrasonic cleaning machine for cleaning.

[0047] (3) Surface phosphating: put the cleaned magnet into the phosphating solution for surface phosphating treatment, the phosphating adopts medium temperature phosphating, the temperature is 50-75°C, and the treatment time is 5-30 minutes.

[0048] (4), metal base layer: adopt spraying process to prepare ZnAl metal base layer on the surface of the magnet after treatment, the specific process is: first spray the front of the magnet, the spray amount is 26g / 30s, the atomization pressure is 0.3-0.5Mpa, dry after spraying, The drying temperature is 120°C, and the drying time is 15 minutes. After the cooled product is turned over, th...

Embodiment 2

[0053] (1) Chamfering and polishing: The surface of the bonded NdFeB magnet is polished by mechanical vibration grinding and rolling chamfering. The final magnetic ring size is: outer diameter 18.8mm×inner diameter 15.8mm×thickness 2.5mm.

[0054] (2) Ultrasonic cleaning: Put the chamfered and polished magnet into an ultrasonic cleaning machine for cleaning.

[0055] (3) Surface phosphating: put the cleaned permanent magnet into the phosphating solution for surface phosphating treatment, the phosphating adopts medium temperature phosphating, the temperature is 50-75°C, and the treatment time is 5-30min.

[0056] (4), metal base layer: adopt spraying process to prepare ZnAl metal base layer on the surface of the magnet after treatment; the specific process is: first spray the front of the magnet, spraying amount 26g / 30s, atomization pressure 0.3-0.5Mpa, drying after spraying, The drying temperature is 120°C, and the drying time is 15 minutes. After the cooled product is turned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com