Simulation lumbar vertebra model for training low-age orthopedist to find optimal screw feeding point of lumbar pedicle screw and manufacturing method

A technology of lumbar pedicle and screw entry point, which is applied in the field of simulated lumbar spine model and production, can solve the problems of reducing the difficulty of simulated surgery and simulation, and achieve the effect of great promotion and application value, low hardware equipment requirements, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

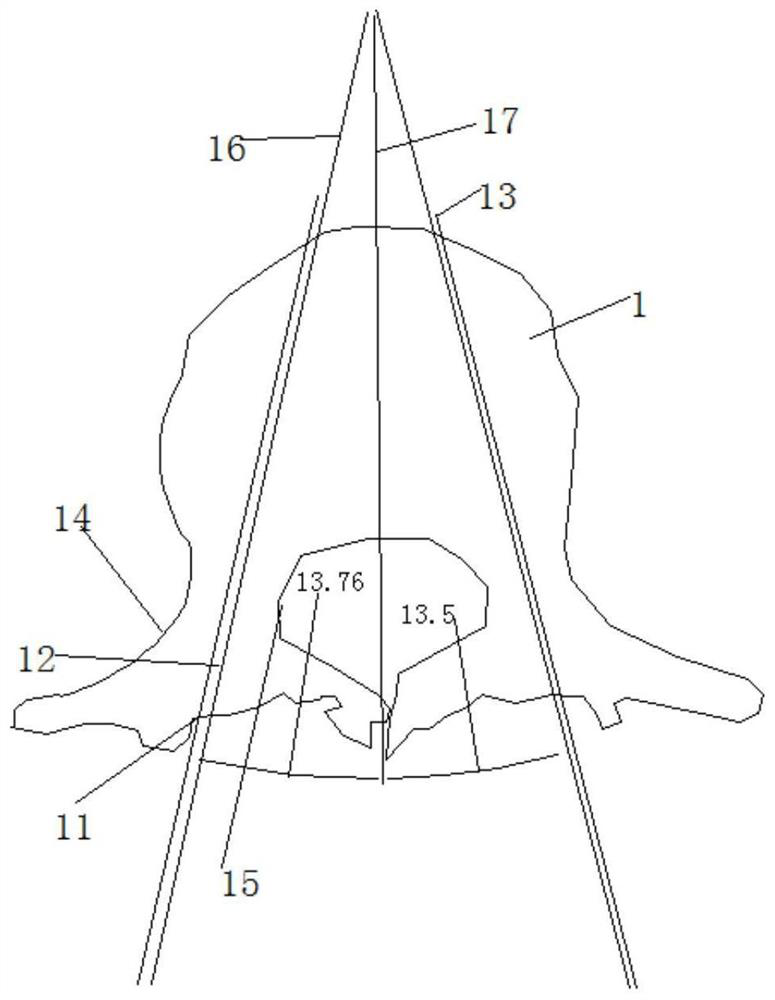

Embodiment 1

[0071] A 3D-printed simulated lumbar spine model for training junior orthopedic surgeons to find the best entry point for lumbar pedicle screws, including skin, muscles and lumbar bones. The lumbar bones are wrapped with vermilion plasticine to simulate human muscles and shaped into adults Finally, it is wrapped with flesh-colored leather to simulate human skin, and a highly simulated human lumbar model is constructed; the lumbar skeleton is equipped with the best channel, the best nail entry point, and alternative channels in the pedicle projection area. Alternative screw entry points, the best entry point is set at the intersection of the best channel and the superior articular process cortex of the vertebral body, connecting with the best channel; the alternative channels are set in parallel around the best channel, covering the pedicle projection area ; The alternative nail entry point is set at the intersection of each alternative channel with the articular process of the ...

Embodiment 2

[0079] The 3D printed simulated lumbar spine model is used to train junior orthopedic surgeons to find the best point for lumbar pedicle screw placement. The specific steps are as follows:

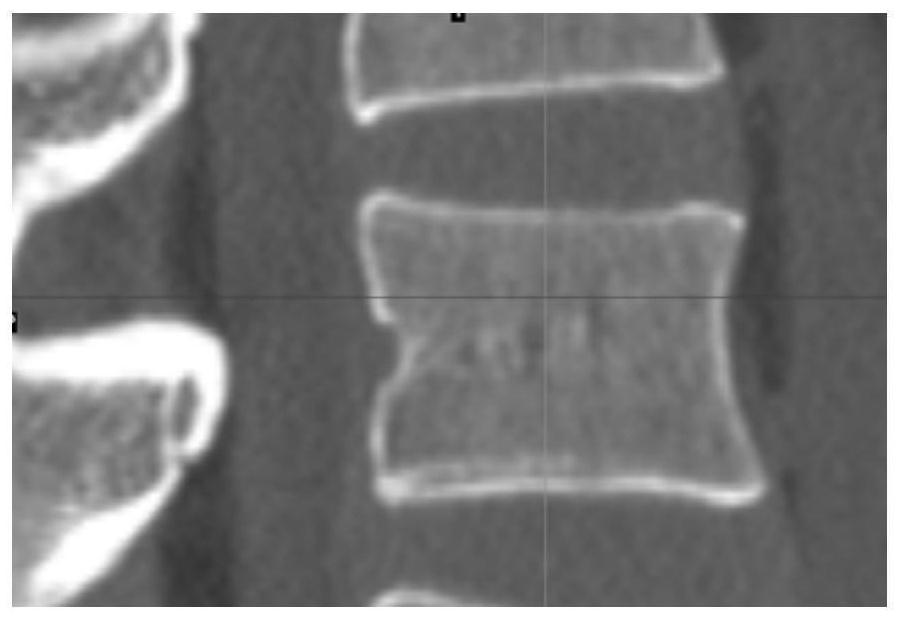

[0080] (1) Collect normal lumbar CT DICOM data, CT scanning conditions: 128-slice spiral CT (Siemens, Germany), voltage 120kV, current 182.25mAs, slice thickness 0.625mm, matrix 512×512 pixels, scan slice thickness 0.625mm.

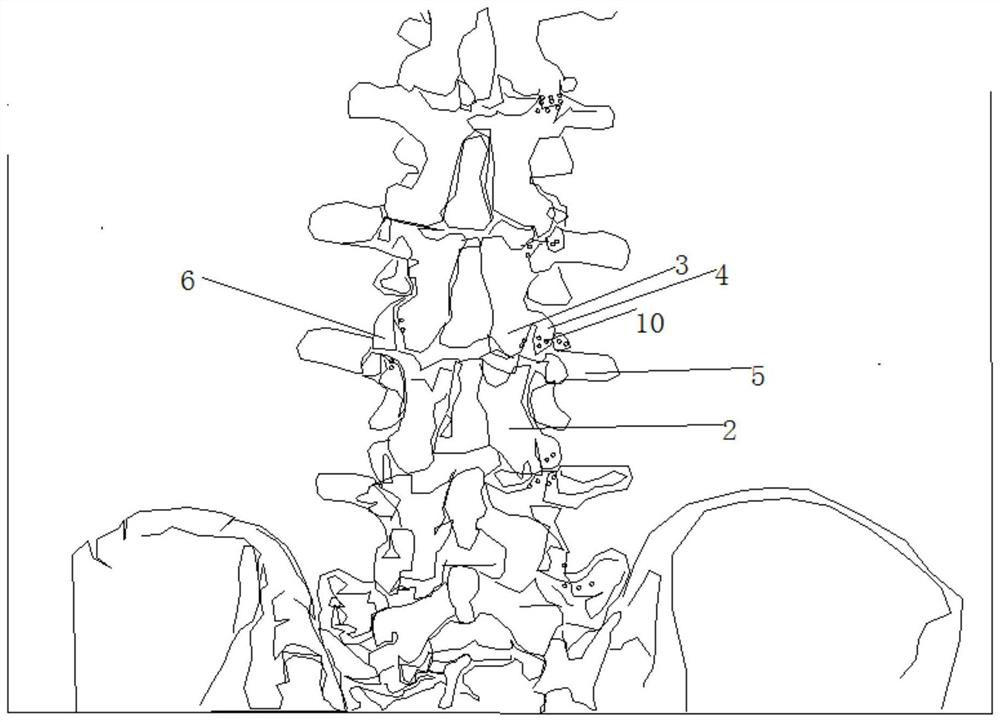

[0081] (2) Establish a 3D lumbar spine three-dimensional model in the three-dimensional reconstruction software: in order to import the normal lumbar spine DICOM data into Mimics19.0 (Materialise Company, Belgium) software, select the minimum threshold value of 150 through the "threshold selection tool" to obtain the lumbar spine Raw mask. Separate the lumbar spine mask to generate a new mask by "segmenting the mask", select the software's default best quality for 3D reconstruction, and obtain a 3D lumbar spine 3D model, such as figure 1 shown.

[0082] (3) The bes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com