Method for realizing aeroelasticity optimization design of turbomachinery by considering random detuning

An aeroelastic, impeller machinery technology, applied in computer-aided design, design optimization/simulation, multi-objective optimization, etc., can solve problems such as blade fatigue failure, accident, blade stress increase, etc., to reduce forced vibration amplitude, reduce sensitivity sex, life-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

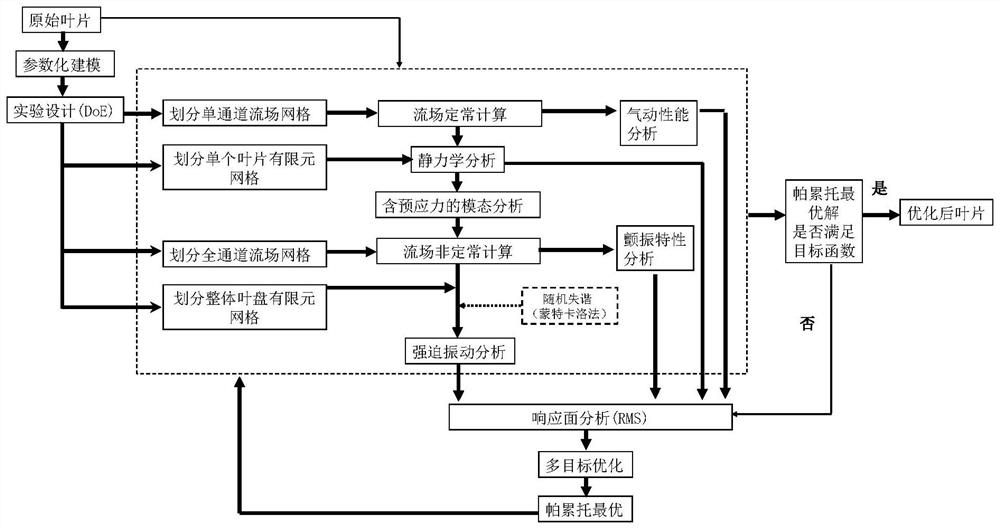

[0047] like figure 1 As shown, this embodiment relates to an optimal design method of turbomachinery aeroelasticity including random detuning, including the following steps:

[0048] Step 1: Select an axial fan blade, and use the function (blade parameter extraction unit) written by Matlab to parameterize the original blade.

[0049] Step 2: Experimental design: According to the number of blade design variables and the upper and lower limits of each variable, use Latin hypercube sampling to generate an appropriate number of experiments.

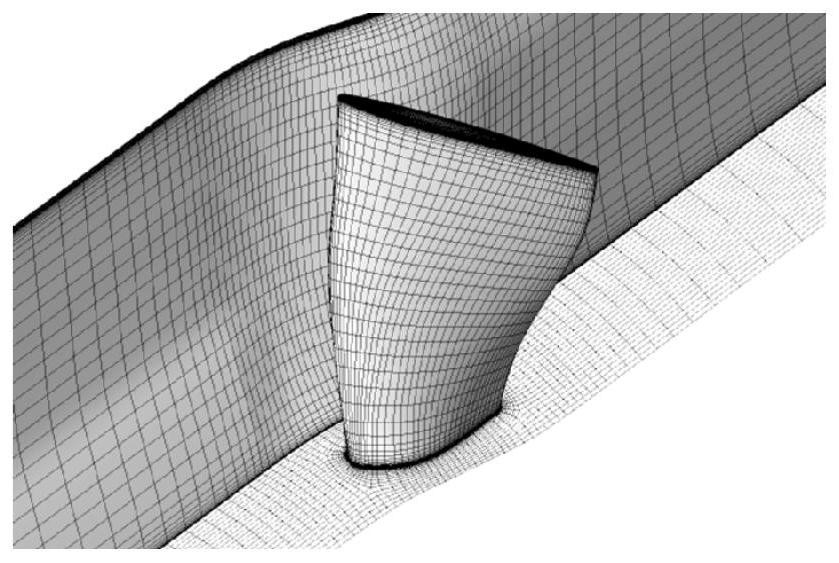

[0050] Step 3: Use the custom Matlab function to drive the Turbogrid module in the computational fluid dynamics software CFX to divide the single-channel grid of the flow field, such as figure 2 shown. The surface of the blade is an O-shaped grid, and the grid scale meets the requirement that Y+ is less than 5. Import the single-channel flow field grid into CFX-Pre, and use Turbo Rotation to copy (N-1) grids with the rotation axis to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com