A tbm equipped with microseismic sensor automatic deployment device

A microseismic sensor and automatic deployment technology, applied in mining equipment, mining equipment, tunnels, etc., can solve problems that threaten the personal safety of workers, and achieve the effect of simplifying the installation process, reducing the volume, and shortening the installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the examples. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0039] The embodiment of the present invention discloses an automatic deployment device for microseismic sensors mounted on a TBM to solve the technical problem in the prior art that the advancement of sensor arrays requires manual disassembly and assembly of sensors, which seriously affects personnel safety and full-time monitoring.

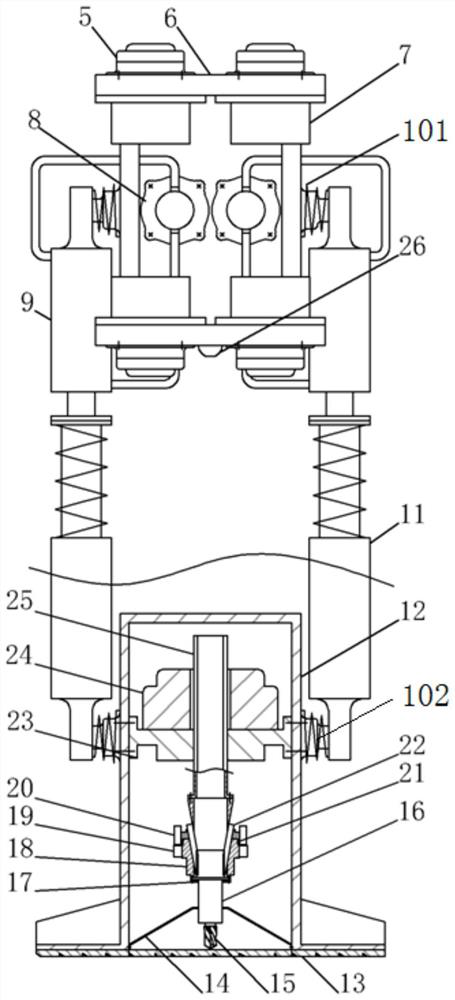

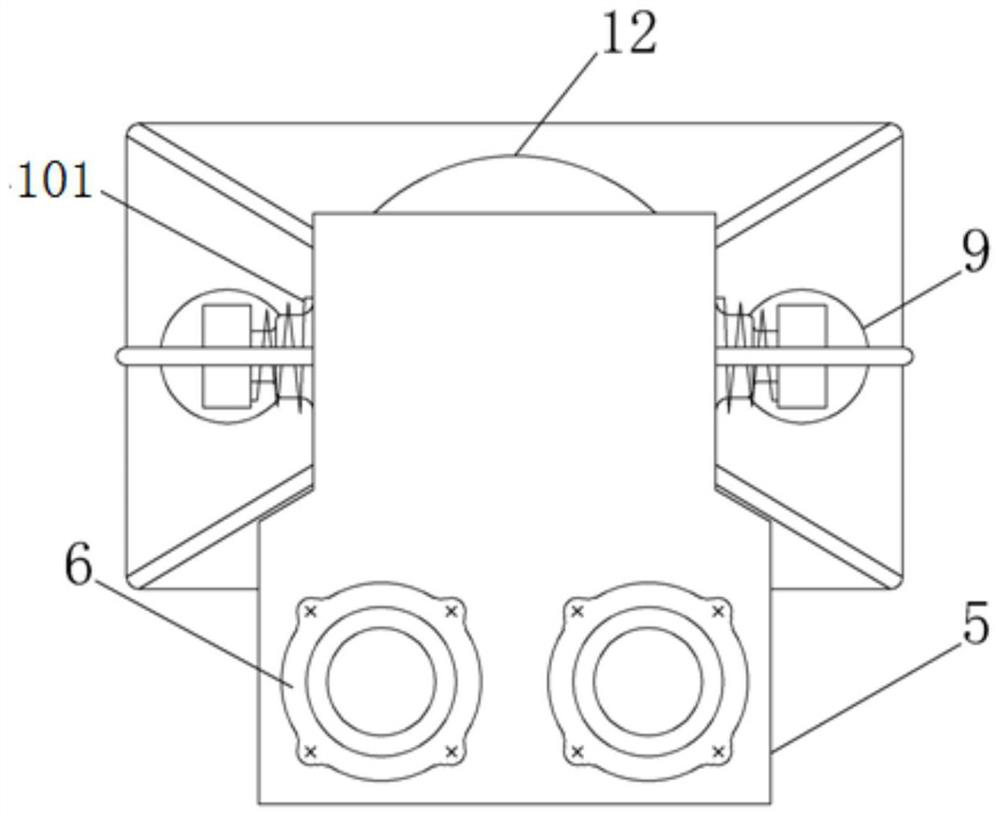

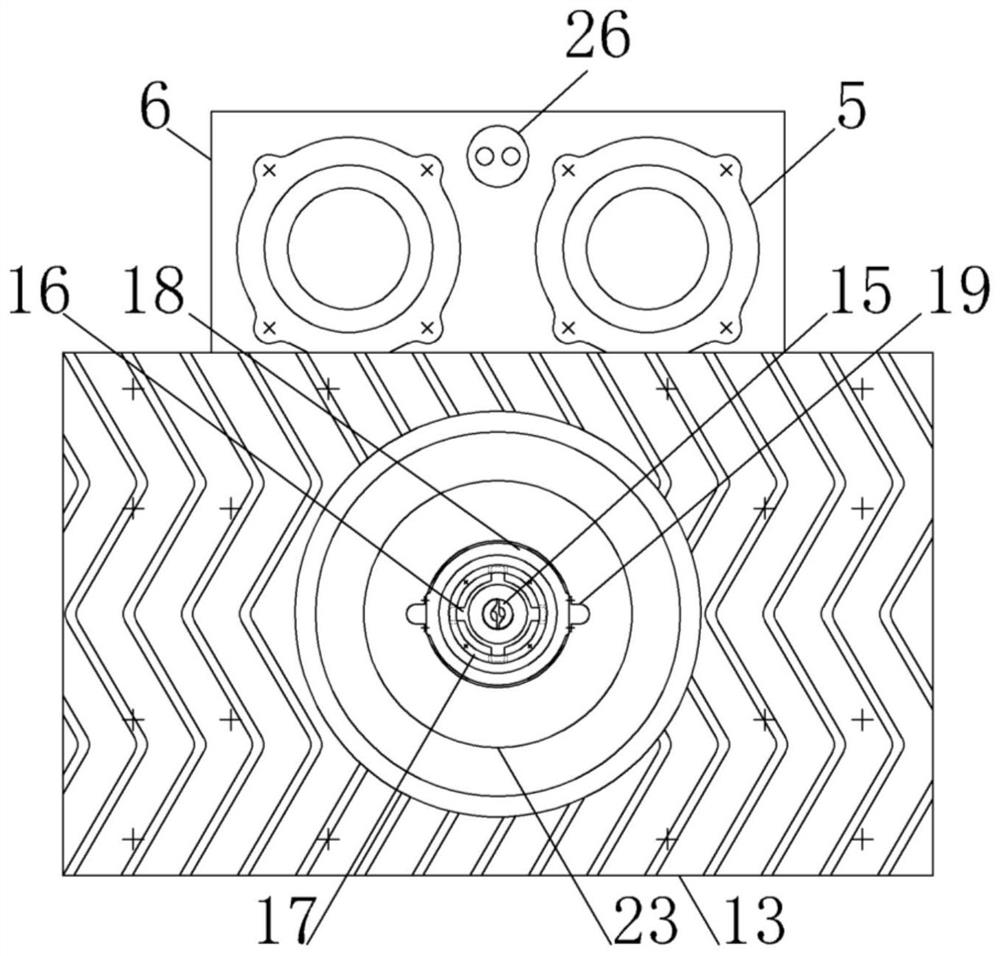

[0040] like Figure 1-Figure 7 As shown, the automatic deployment device 3 of the embodiment of the present invention is installed on the H-shaped steel rail 4, and its anti-skid pad 13 is close to the rock wall 1. The H-shaped steel rail is welded o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com