A kind of method for removing fluorine from lepidolite roasting leaching solution

A leachate and lepidolite technology, applied in the direction of improving process efficiency, lithium carbonate;/acid carbonate, etc., can solve problems such as non-compliance with use requirements, affecting product quality, etc., to improve quality and reduce operating costs , The effect of high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

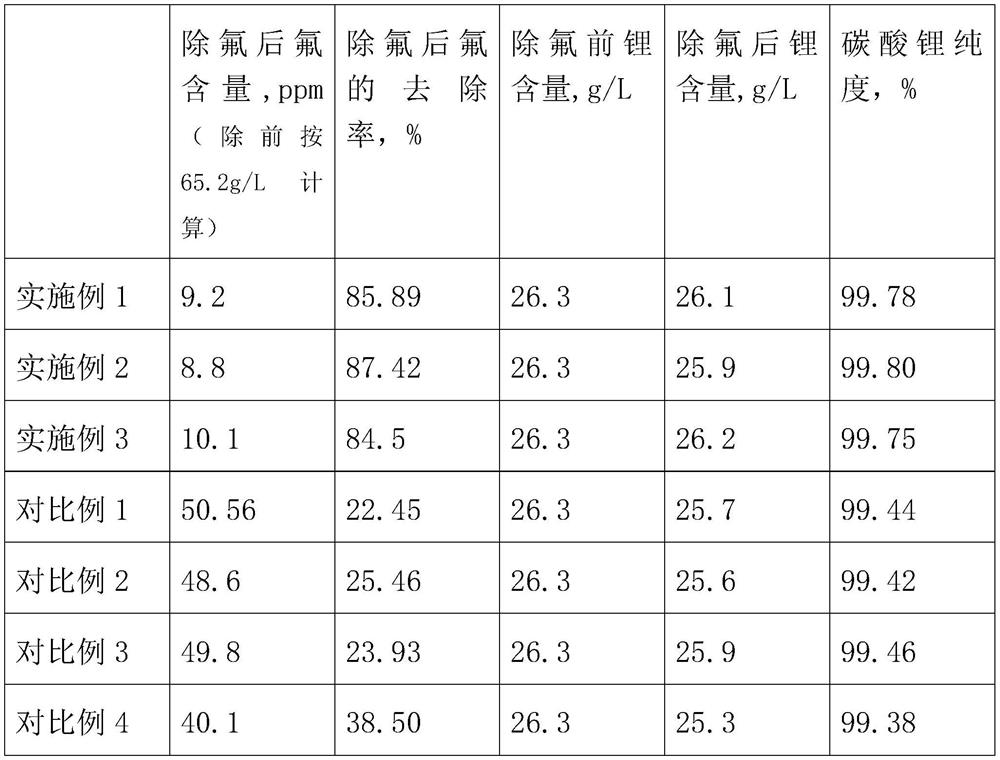

Examples

Embodiment 1

[0017] A method for removing fluorine from lepidolite roasting leaching solution, specifically:

[0018] The leaching solution obtained by leaching the lepidolite after roasting, according to the leaching solution 1m 3 Add 2-6 kg of defluorinating agent, stir evenly, keep at 40-60 °C, adjust pH to 6.5 after sufficient reaction, and filter after sedimentation ≥ 1 h to obtain a filtrate with reduced fluorine content for use in battery grades In the preparation of lithium carbonate, the filter residue can be used as an auxiliary material for roasting.

[0019] Wherein, the fluorine removing agent is a mixture of aluminum sulfate, aluminum oxide and silicon dioxide.

[0020] Wherein, the mass ratio of aluminum sulfate, aluminum oxide, and silicon dioxide in the mixture is 7.8:1.8:0.4.

Embodiment 2

[0022] A method for removing fluorine from lepidolite roasting leaching solution, specifically:

[0023] The leaching solution obtained by leaching the lepidolite after roasting, according to the leaching solution 1m 3 Add 2-6 kg of fluorine-removing agent to the fluorine-removing agent, stir evenly, keep the temperature at 30 °C, adjust the pH to 5.5 after sufficient reaction, settle for 2 hours, and filter to obtain a filtrate with a reduced fluorine content for use in battery-grade lithium carbonate. Preparation, the filter residue can be used as an auxiliary material for roasting.

[0024] Wherein, the fluorine removing agent is a mixture of aluminum sulfate, aluminum oxide and silicon dioxide.

[0025] Wherein, the mass ratio of aluminum sulfate, aluminum oxide, and silicon dioxide in the mixture is 7.8:1.8:0.4.

Embodiment 3

[0027] A method for removing fluorine from lepidolite roasting leaching solution, specifically:

[0028] The leaching solution obtained by leaching the lepidolite after roasting, according to the leaching solution 1m 3 Add 4-5 kg of fluorine-removing agent to the fluorine-removing agent, stir evenly, keep the temperature at 50 °C, adjust the pH to 7.0 after fully reacting, and filter for 4 hours after settling to obtain a filtrate with a reduced fluorine content for use in battery-grade lithium carbonate. Preparation, the filter residue can be used as an auxiliary material for roasting.

[0029] Wherein, the fluorine removing agent is a mixture of aluminum sulfate, aluminum oxide and silicon dioxide.

[0030] Wherein, the mass ratio of aluminum sulfate, alumina, and silicon dioxide in the mixture is 7:2:0.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com