Preparation method of degradable poly-alpha-olefin material with controllable olefin insertion rate

A technology of insertion rate and olefin, applied in the field of polyolefin materials, to achieve the effects of safety and environmental protection in the production process, mild reaction conditions, and high reaction conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

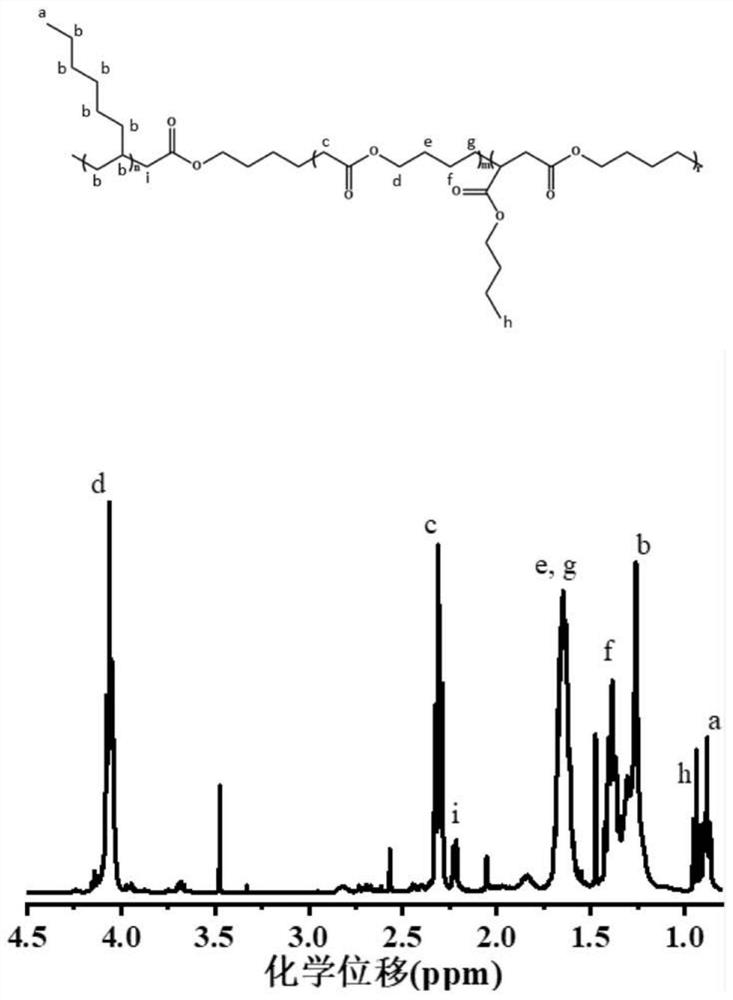

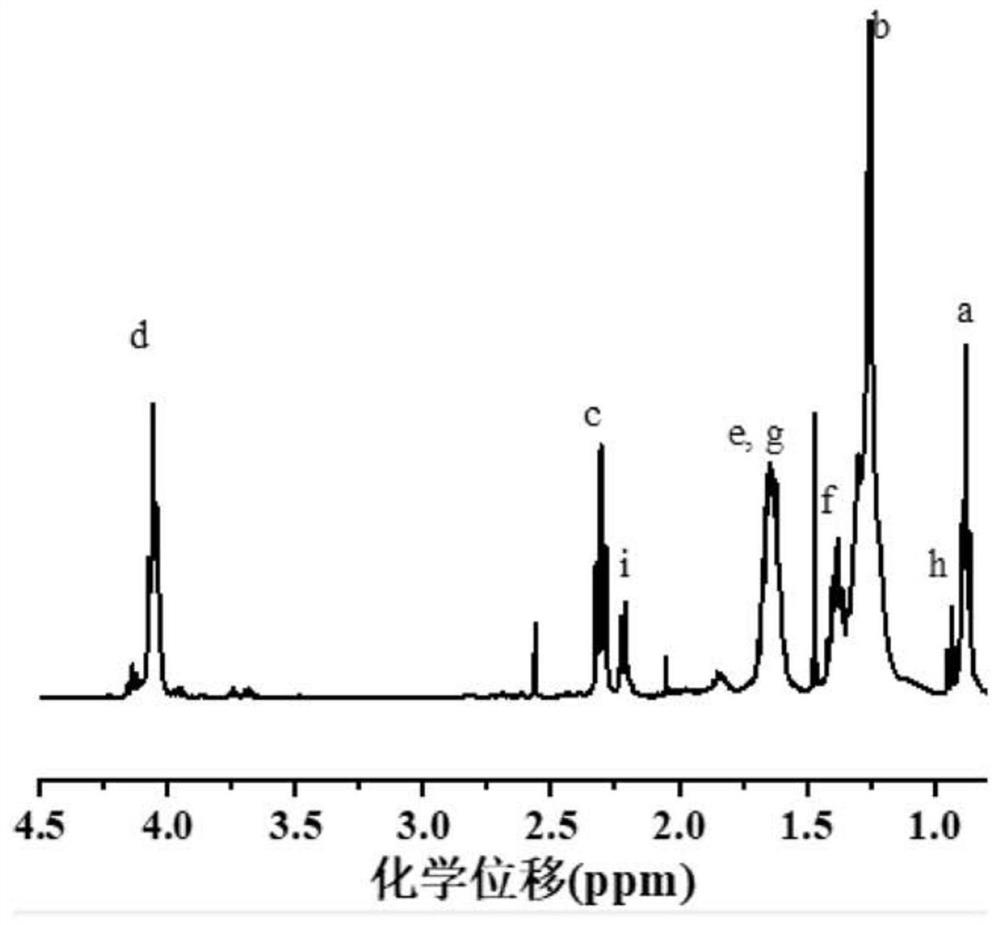

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing degradable polyalphaolefins with mild reaction conditions and adjustable olefin insertion rate, comprising the following steps:

[0026] Under the irradiation of visible light, cyclic ketene acetal, α-diimine palladium catalyst, nucleophile and α-olefin are dissolved in a solvent for reaction to obtain a degradable poly α-olefin material.

[0027] In the preparation method of the present disclosure, firstly, the cycloalkene acetal, the α-diimine palladium catalyst, and the nucleophile are dissolved in a solvent to obtain a mixed solution.

[0028] In this disclosure, the term "cycloketene acetal" refers to a class of cyclic compounds containing an exocyclic methylene group connected to two oxygen atoms in the structure, and the number of carbon atoms can range from 6 to 12 Inside. Examples of the cycloalkene acetal may be selected from 2-methylene-1,3-dioxane, 2-methylene-1,3-dioxetane, 4,7-dioxane Methyl-2-methylene-1,3-d...

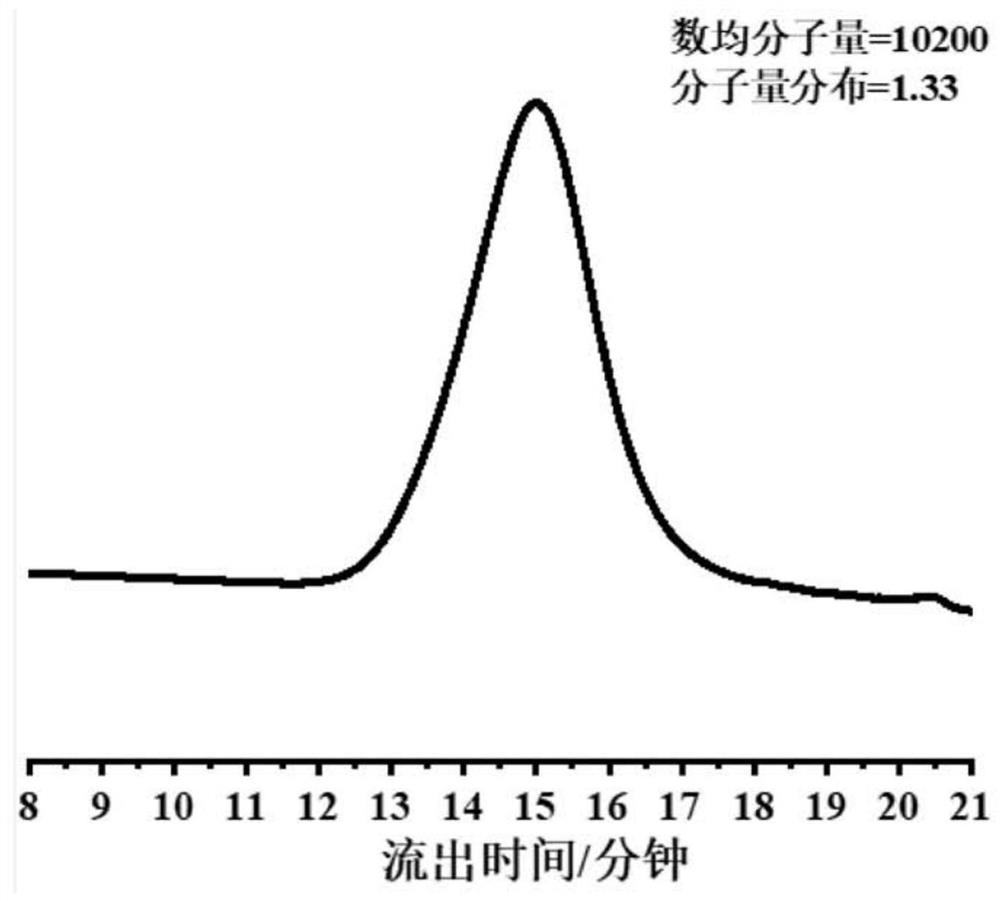

Embodiment 1

[0057] 1.0g 2-methylene-1,3-dioxetane, 0.5g chloroform, 0.005g N,N'-bis(2,6-isopropylphenyl)butyl-2,3 - Diimine-coordinated methylpalladium chloride and 0.005g bis-(triphenylphosphoryl)ammonium chloride were mixed evenly, placed in a 5mL sealed tube, 0.25g of 1-octene was added, and after stirring The mixture was irradiated under 450nm blue light (40W) and reacted for 24 hours.

[0058] Dissolve the crude polymerization mixture in 5 mL of chloroform, add dropwise to 50 mL of methanol to precipitate, then centrifuge to remove methanol, redissolve the resulting precipitate in chloroform, add dropwise to excess methanol, remove methanol and dry under vacuum . The degradable polyalpha-olefin 1 can be obtained.

Embodiment 2

[0060] The experiment was carried out in a method similar to that of Example 1, except that 0.5 g of 1-octene was added to obtain degradable polyα-olefin 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com