Lifting mechanism in AGV, and conveying AGV capable of achieving double-row independent lifting

A lifting mechanism and independent lifting technology, applied in the field of AGV, can solve problems such as affecting work efficiency, insufficient scalability, and difficulty in adapting AGV to achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

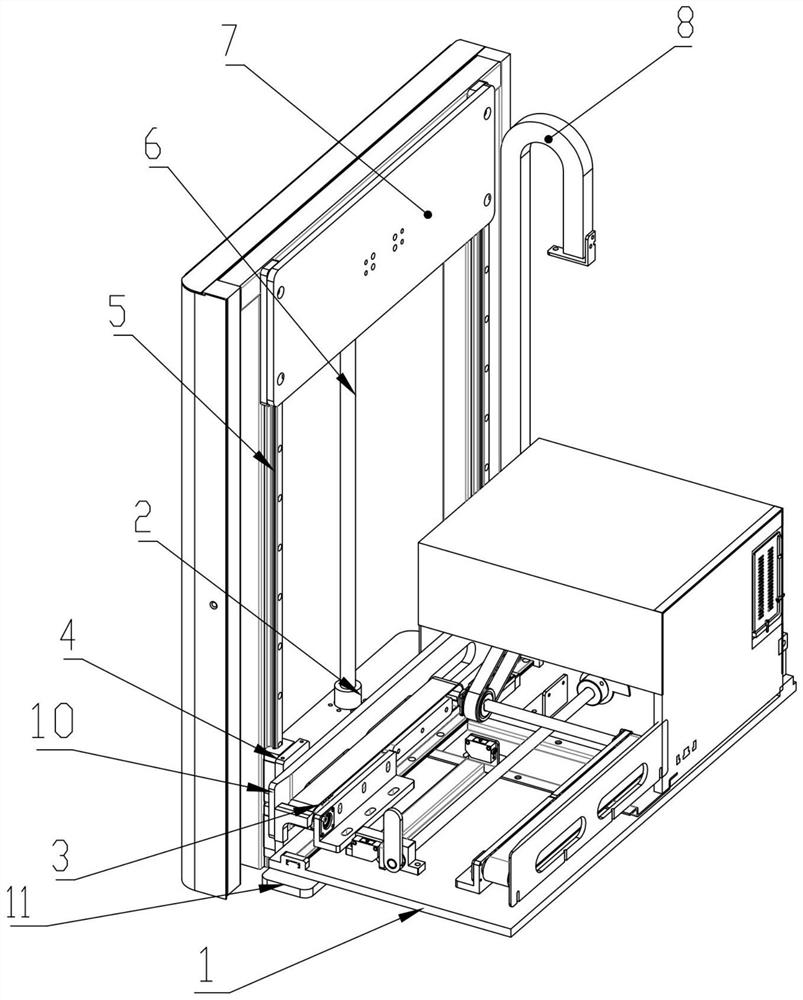

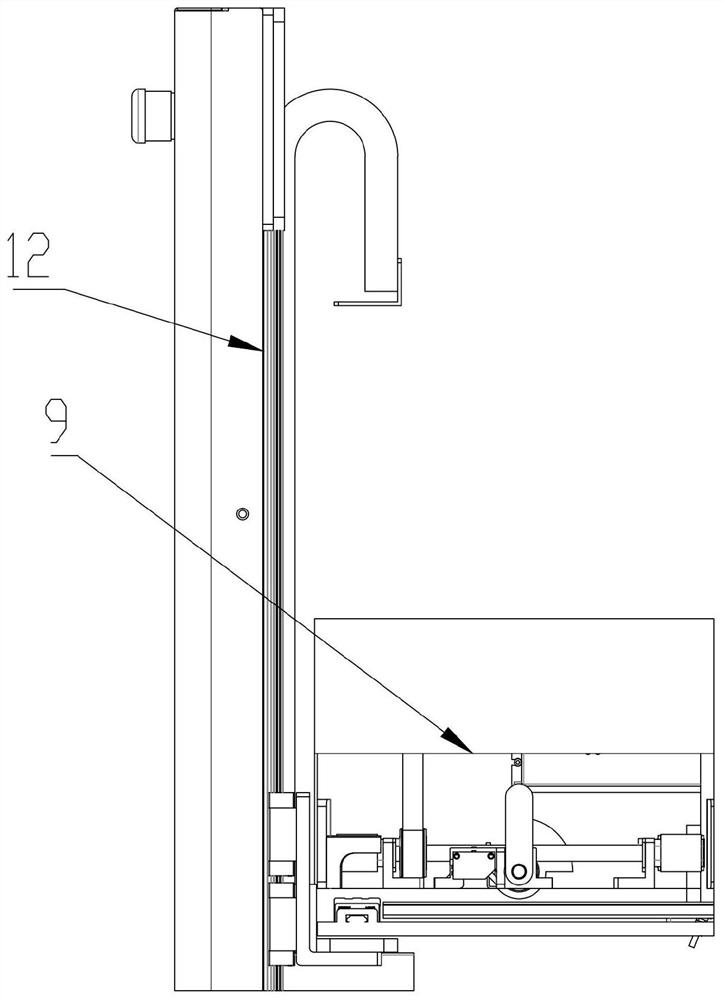

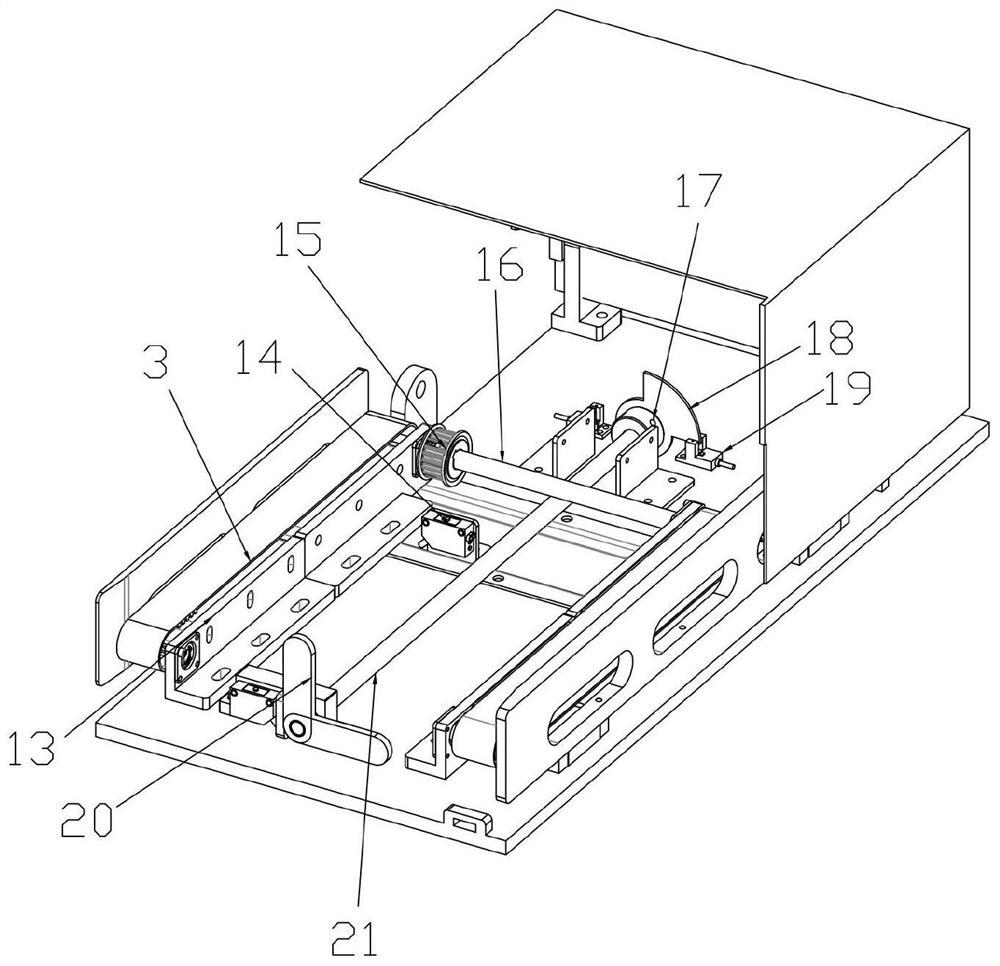

[0048] as attached figure 1 and 2 As shown, a lifting mechanism in an AGV provided by an embodiment of the present invention, the lifting mechanism includes:

[0049] A vertical plate 12 provided with a linear guide rail 5;

[0050] The main assembly of the lifting mechanism; the main assembly of the lifting mechanism has a sliding part, a conveying part and a stopper, and the sliding part can make the main assembly of the lifting mechanism slide along the linear guide rail 5; the conveying part is used for receiving and receiving from the outside sending materials to the outside; the blocking member is used to block the materials on the conveying part, so as to prevent the materials from falling out of the conveying part;

[0051] The power part is used to drive the main assembly of the lifting mechanism to slide along the linear guide rail 5 .

[0052] Specifically, when the lifting mechanism is working, the material is first received from the outside through the conveyin...

Embodiment 2

[0084] as attached Figure 4 and 5 As shown, another purpose of the embodiment of the present invention is to provide a double-row independently lifting conveying AGV, including an AGV body 40, a power mechanism 41 and a differential wheel 42. The AGV body 40 includes two pieces with different installation directions. The lifting mechanism 30 described in any one of Embodiment 1.

[0085] Specifically, the AGV body 40 of the present invention is not different from the existing AGV body 40, and both have a power mechanism 41, a differential wheel 42, and the like. Common mechanisms in AGVs such as other navigation mechanisms and control mechanisms can also be found in the AGV of the present invention. The difference is that the AGV of the present invention has improved the lifting mechanism in the existing AGV, and changed a single row of lifting mechanisms in the existing AGV into two lifting mechanisms 30 in Embodiment 1, making the AGV of the present invention a An AGV wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com