Powder bonding 3D printing equipment and method for preparing complex geologic model

A powder-bonded, complex geological technology, applied in metal processing equipment, 3D object support structures, additive manufacturing, etc., can solve the problems of slow printing, small coverage, and inability to perform subtractive manufacturing such as cutting cracks, etc. Improve printing efficiency and printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

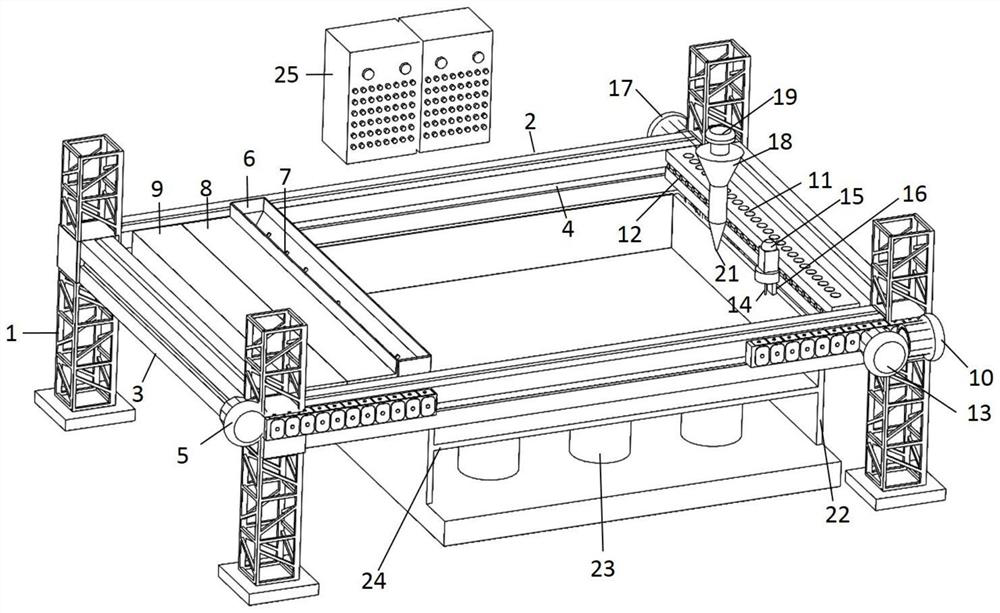

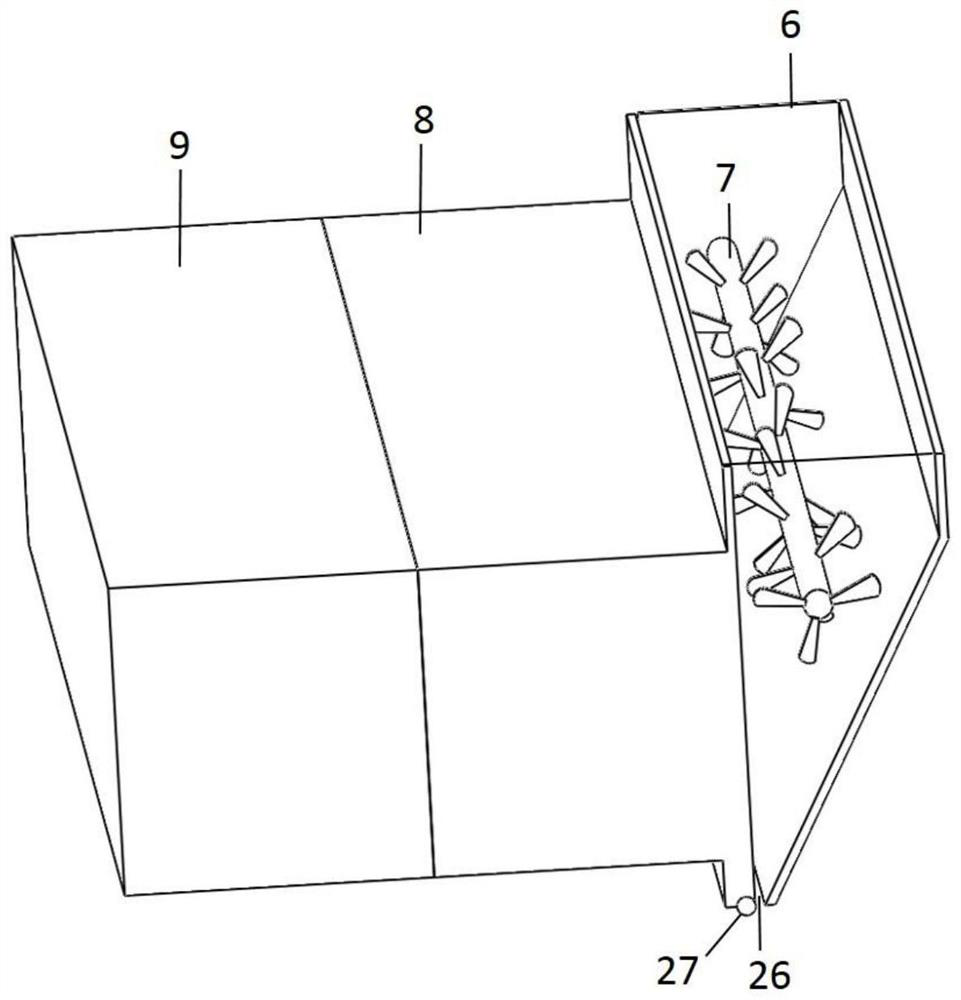

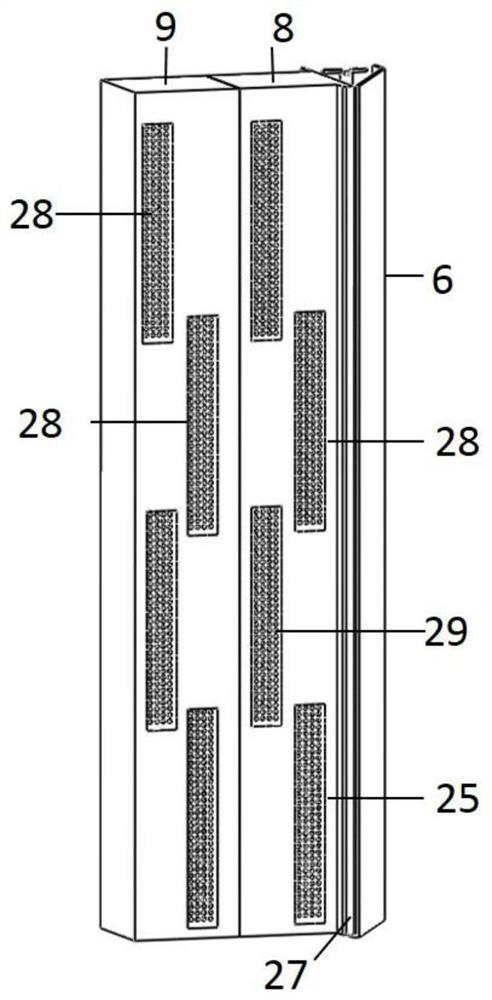

[0031] The present invention provides a powder bonding 3D printing device (equipment for short) for preparing complex geological models, which is characterized in that the device includes a frame, a transverse guide rail 4, a stepping motor 5 of a powder bonding assembly, a powder bonding assembly , Small longitudinal beam stepping motor 10, small longitudinal beam 11, longitudinal guide rail 12, crack cutting device stepping motor 13, crack cutting device, crack filling device stepping motor 17, crack filling device, lifting molding chamber and control system 25;

[0032] The frame is provided with a transverse guide rail 4, a stepping motor 5 for the powder-spreading and bonding assembly, a stepping motor 10 for the small longitudinal bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com