Steam constant-temperature curing process for foam core material production process and curing room of steam constant-temperature curing process

A foam core material and a production process technology, applied in the foam core material field, can solve the problems of scalding in a melting furnace, affecting personal safety, and high surface temperature of a melting cylinder, achieving the effects of good quality, personal safety protection, and simple melting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

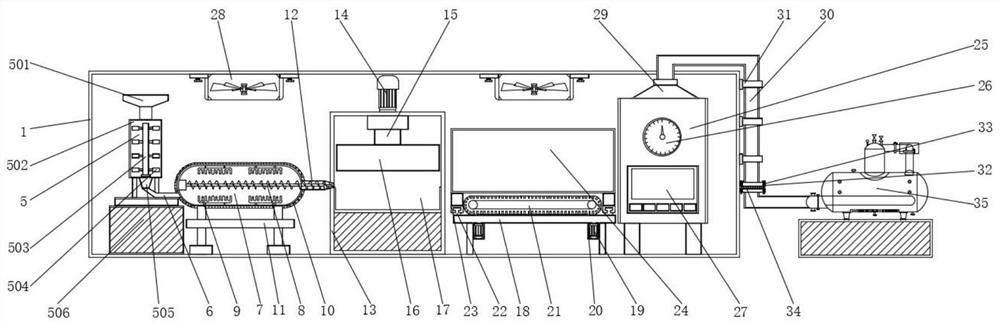

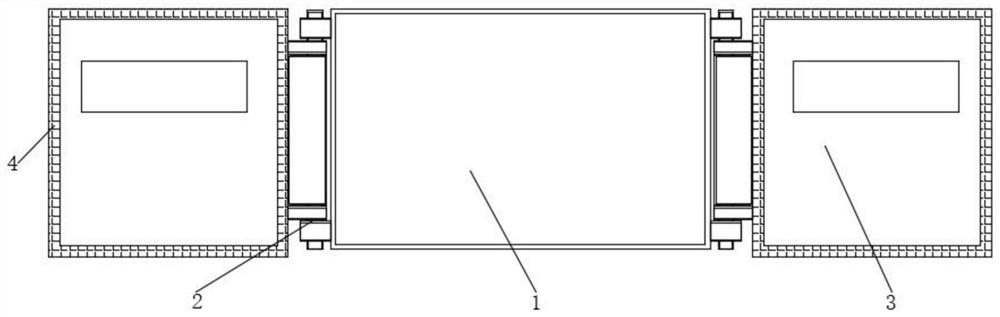

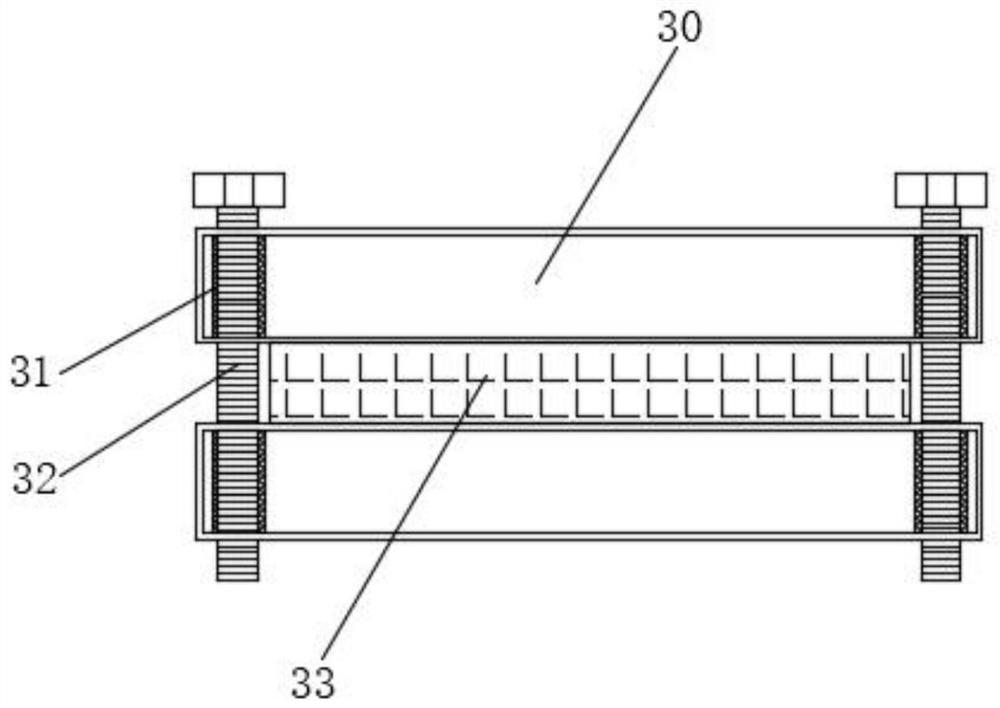

[0041] see Figure 1-6 , in this embodiment: a foam core material production process steam constant temperature curing process and its curing room, including the production bin 1 and the feeding mechanism 5; Warehouse door 3, at the same time the warehouse door 3 is installed with the sealing strip 4, the inner side of the production warehouse 1 is provided with a feeding mechanism 5, and the outer side of the feeding mechanism 5 is provided with a connecting pipe 6, and the connecting pipe 6 is installed with the melting cylinder 7 at the same time, melting The inside of the cylinder 7 is provided with a screw shaft 8, and the inside of the melting cylinder 7 is provided with a heating plate 9. At the same time, the melting cylinder 7 is installed in conjunction with the heat insulation pad 10. The bottom of the melting cylinder 7 is provided with a support frame 11, and the outside of the melting cylinder 7 is provided There is an injection rod 12. At the same time, the inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com