Preparation method and application of g-C3N4 (101)-(001)-TiO2 composite material

A composite material, g-c3n4 technology, applied in the field of preparation of g-C3N4/--TiO2 composite materials, can solve the problems of limited photocatalytic performance, poor electronic conductivity, small specific surface area, etc., and achieve a simple and easy-to-control preparation method, The effect of improving catalytic ability and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1g-C 3 N 4 Powder Preparation Method

[0035] Weigh a certain amount of urea into a porcelain crucible with a cover, place it in a blast drying oven until the urea is completely dry, then move it to a muffle furnace, and raise the temperature to 550°C at a heating rate of 5°C / min. And kept for 3h, finally got the light yellow g-C 3 N 4 powder.

Embodiment 2

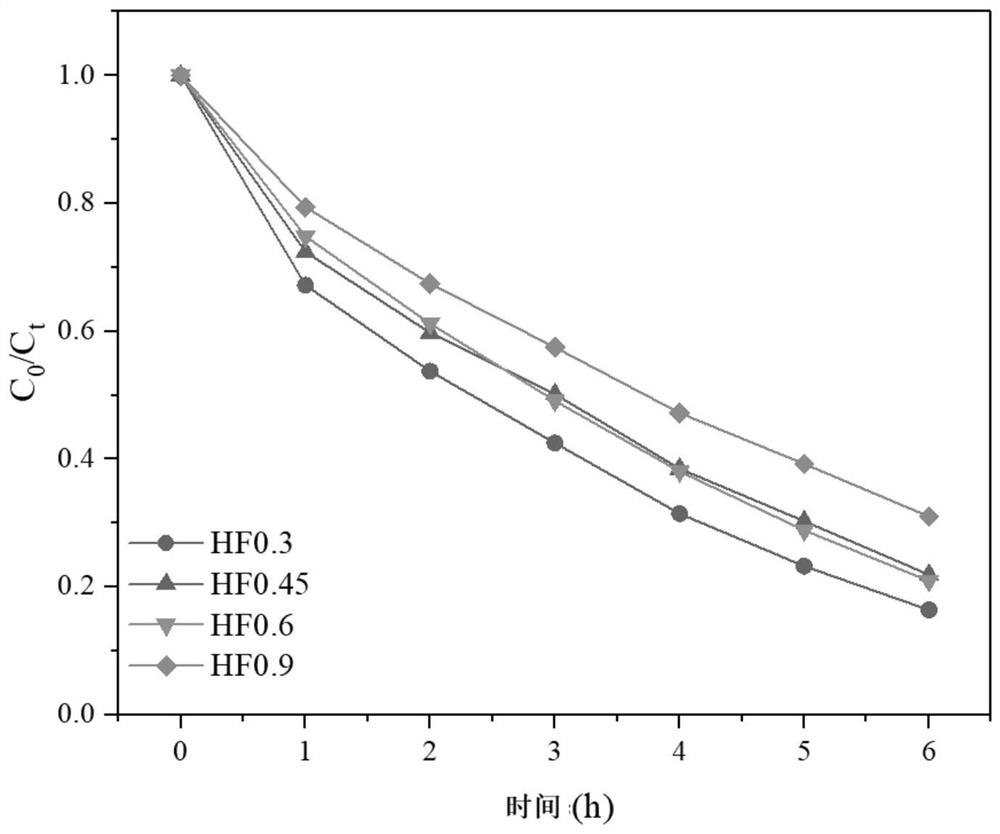

[0036] Example 2(101)-(001)-TiO 2 preparation method

[0037] Under the condition of stirring, measure 2.5mL of tetrabutyl titanate solution and slowly add it into 100mL of polytetrafluoroethylene lined with 30mL of absolute ethanol. After the solution is stirred evenly (30min), measure 0.3mL A hydrofluoric acid solution with a concentration of 40% was slowly added to the above solution, and stirring was continued for 30 min. Then the autoclave was transferred to a blast drying oven, and the heating was continued at 180° C. for 12 h. After the sample was cooled to room temperature, it was centrifuged, washed with absolute ethanol and deionized water, and dried to collect the solid. The solid was then ground into a powder and put into a crucible with a cover and placed in a muffle furnace. At a heating rate of 5°C / min, it was raised to 550°C and kept for 2h for annealing to obtain the final sample (101)-(001)-TiO 2 .

Embodiment 3

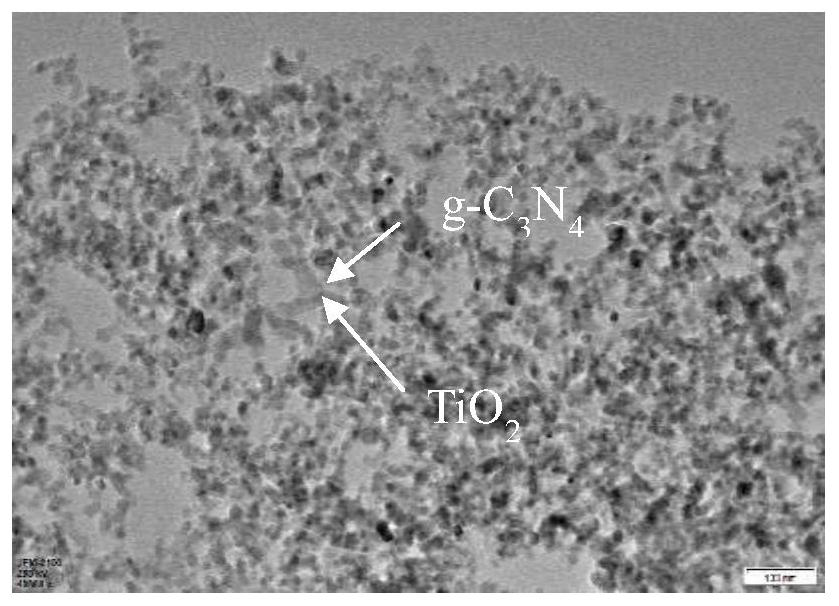

[0038] Example 3g-C 3 N 4 / (101)-(001)-TiO 2 Preparation method of composite material

[0039] The g-C of the embodiment 1 gained of taking 1.15g 3 N 4 Add the powder into a 100mL polytetrafluoroethylene liner containing 30mL of absolute ethanol and continue to stir for 1h. After the solution is evenly mixed, measure 2.5mL of tetrabutyl titanate solution and slowly add it to the solution, and continue to stir for 30min. , and then measure 0.3 mL of hydrofluoric acid (40%) solution and slowly add it into the above mixed solution, and stir for 30 min until a uniform solution is formed. Then the autoclave was transferred to a blast drying oven, and the heating was continued at 180° C. for 12 h. After the sample was cooled to room temperature, it was centrifuged, washed with absolute ethanol and deionized water, and dried to collect the solid. The solid was then ground into a powder and put into a crucible with a cover and placed in a muffle furnace. At a heating rate of 5°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com