Internal heating cooking containers and cooking utensils

A technology for cooking utensils and cooking containers, which is applied to steam cooking utensils, cooking utensils, shells/sleeves of cooking utensils, etc., can solve problems such as condensation of condensed water, and achieve the effect of balancing the temperature difference between inside and outside, weakening the condensation effect and reducing the amount of condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

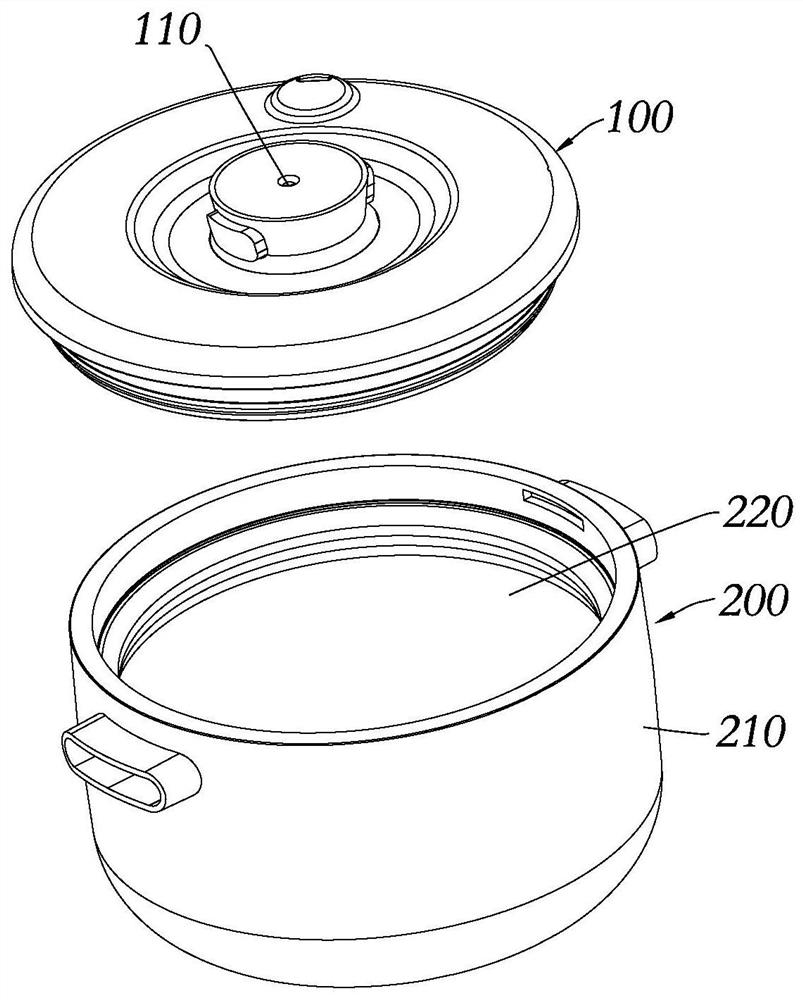

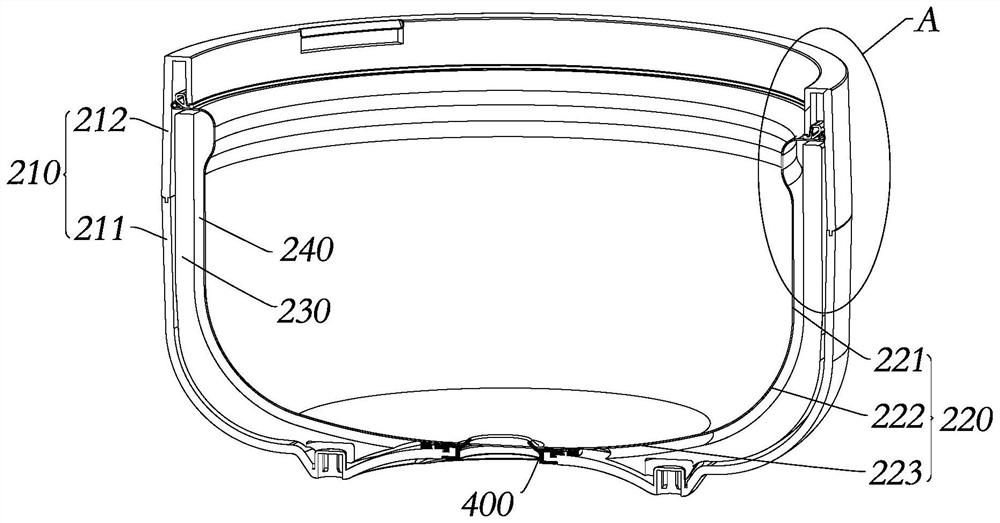

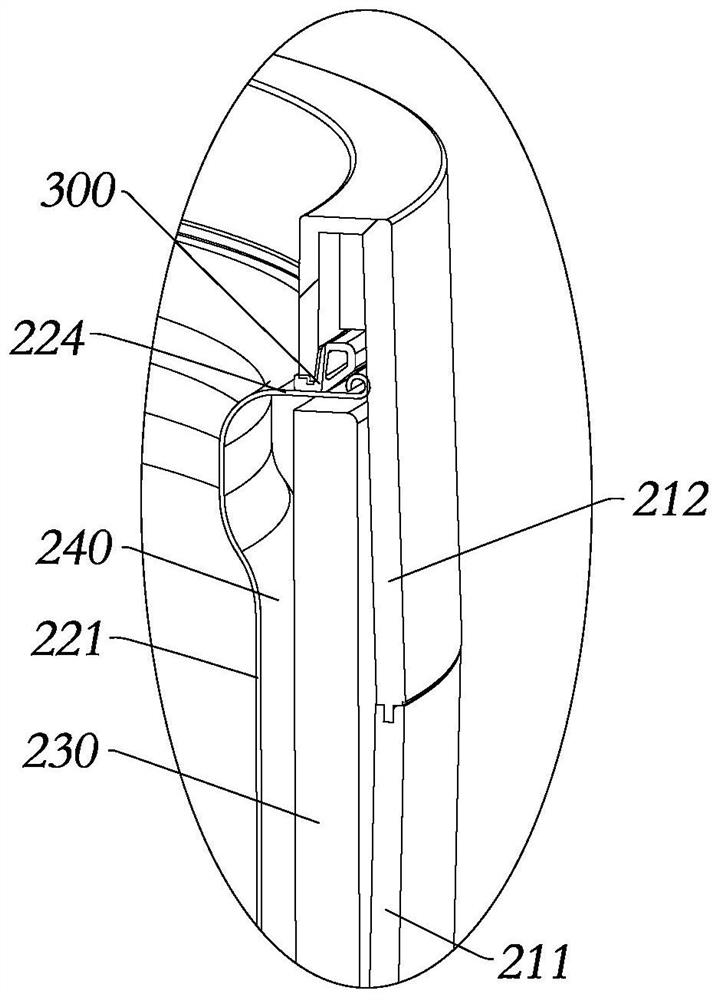

[0034] The internal heating type cooking container proposed by the present invention includes a pot body and a pot cover, the pot body includes an outer body and an inner body, a cavity is formed between the outer body and the inner body, and the cavity The cavity is provided with a heat-locking layer and a heat-insulating layer, the inner tank body and the heat-insulating layer are separated by the heat-locking layer, and the heat-locking layer is an air layer used to balance the temperature difference inside and outside the inner tank . During the cooking process, the temperature of the heat-locking layer can be close to the internal temperature of the inner tank in a short period of time, that is, it can balance the temperature difference between the inner and outer tanks, thus weakening the condensation effect inside the inner tank, that is, reducing the internal temperature of the inner tank. The amount of condensed water on the inner wall of the tank avoids the problem o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com