Cross-linked polyethylene insulated halogen-free low-smoke fire-resistant control cable

A cross-linked polyethylene, control cable technology, applied in insulated cables, insulated conductors, organic insulators, etc., can solve the problems of lack of cooling process, lack of feeding mechanism, poor overall extrusion quality, etc., to improve stirring efficiency, expand Scope of application, effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

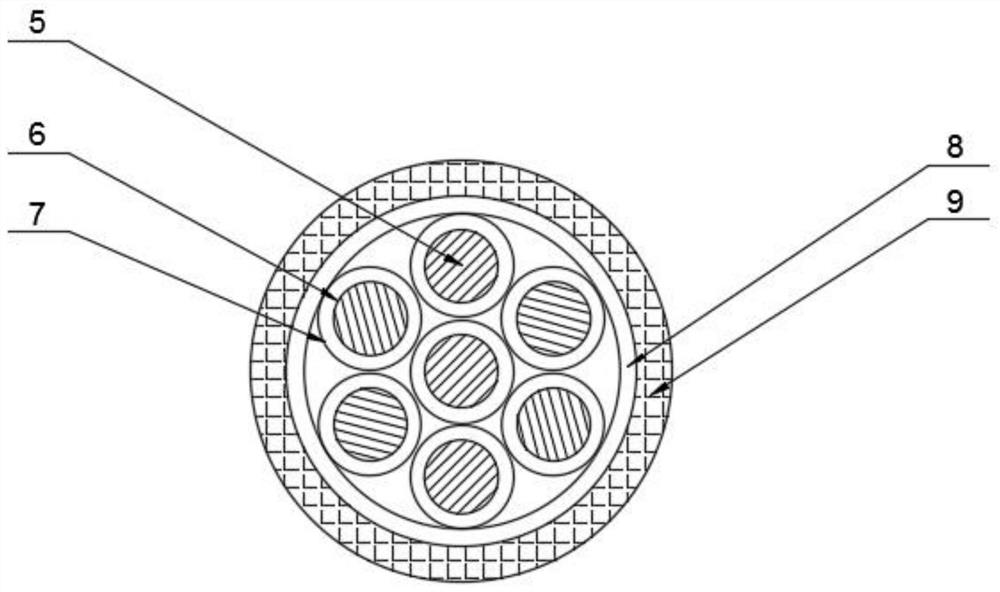

[0049]A cross-linked polyethylene insulated halogen-free low-smoke fire-resistant control cable, comprising a conductor, a fire-resistant mica layer, an insulating layer, a tape layer and a sheath layer. The conductor is wrapped with a fire-resistant mica layer, and the fire-resistant mica layer is wrapped with insulation The conductor, the fire-resistant mica layer and the insulating layer constitute an insulated wire core. Several insulated wire cores are twisted into a bundle to form a cable core. The outside of the cable core is wrapped with a tape layer, and the outside of the tape layer is wrapped with a sheath layer;

[0050]The conductor is composed of annealed copper wire, the refractory mica layer is wrapped by mica tape; the insulating layer is composed of cross-linked polyethylene, the wrapping layer is wrapped by alkali-free glass fiber tape, and the sheath layer is made of halogen-free resistance. Composition of burning polyolefin;

[0051]The cross-linked polyethylene inclu...

Embodiment 2

[0064]A cross-linked polyethylene insulated halogen-free low-smoke fire-resistant control cable, comprising a conductor, a fire-resistant mica layer, an insulating layer, a tape layer and a sheath layer. The conductor is wrapped with a fire-resistant mica layer, and the fire-resistant mica layer is wrapped with insulation The conductor, the fire-resistant mica layer and the insulating layer constitute an insulated wire core. Several insulated wire cores are twisted into a bundle to form a cable core. The outside of the cable core is wrapped with a tape layer, and the outside of the tape layer is wrapped with a sheath layer;

[0065]The conductor is composed of annealed copper wire, the refractory mica layer is wrapped by mica tape; the insulating layer is composed of cross-linked polyethylene, the wrapping layer is wrapped by alkali-free glass fiber tape, and the sheath layer is made of halogen-free resistance. Composition of burning polyolefin;

[0066]The cross-linked polyethylene inclu...

Embodiment 3

[0079]A cross-linked polyethylene insulated halogen-free low-smoke fire-resistant control cable, comprising a conductor, a fire-resistant mica layer, an insulating layer, a tape layer and a sheath layer. The conductor is wrapped with a fire-resistant mica layer, and the fire-resistant mica layer is wrapped with insulation The conductor, the fire-resistant mica layer and the insulating layer constitute an insulated wire core. Several insulated wire cores are twisted into a bundle to form a cable core. The outside of the cable core is wrapped with a tape layer, and the outside of the tape layer is wrapped with a sheath layer;

[0080]The conductor is composed of annealed copper wire, the refractory mica layer is wrapped by mica tape; the insulating layer is composed of cross-linked polyethylene, the wrapping layer is wrapped by alkali-free glass fiber tape, and the sheath layer is made of halogen-free resistance. Composition of burning polyolefin;

[0081]The cross-linked polyethylene inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com