Fuel injection and atomization combustion test device suitable for large-gradient shear flow

A technology of combustion test and shear flow, which is applied in the field of aviation, can solve the problems of difficult complete combustion of fuel, unstable flame, and difficult ignition, and achieve the effects of preventing coking, improving atomization effect, and solving ignition difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to clearly illustrate the technical characteristics of this patent, the following describes this patent in detail through specific implementation methods and in conjunction with the accompanying drawings.

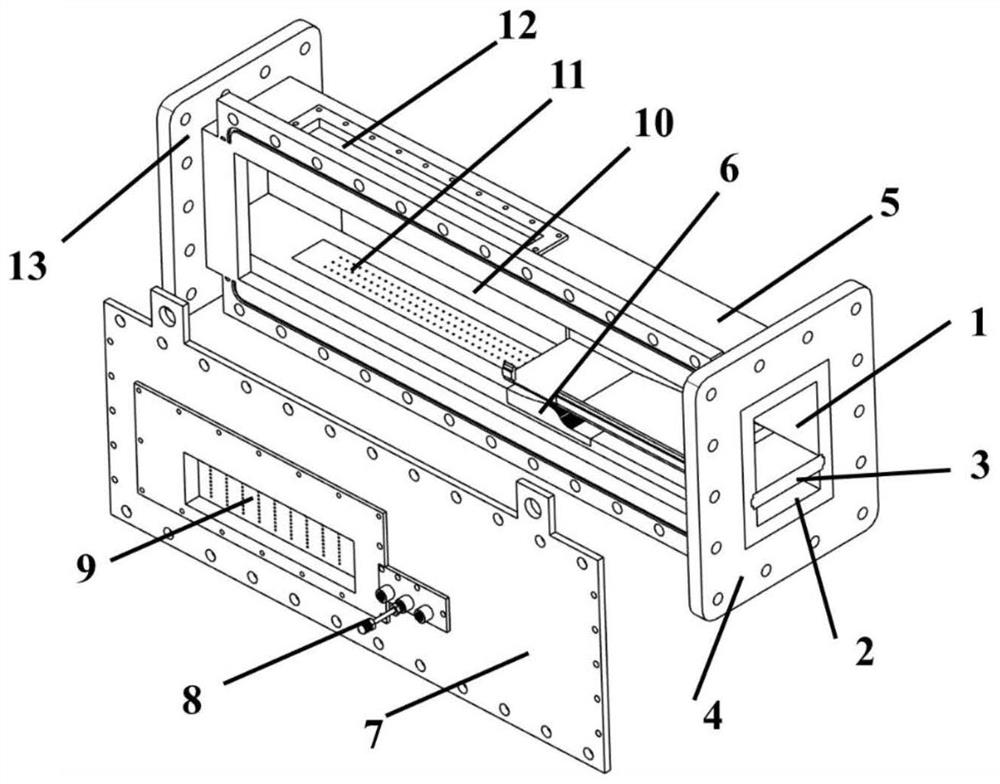

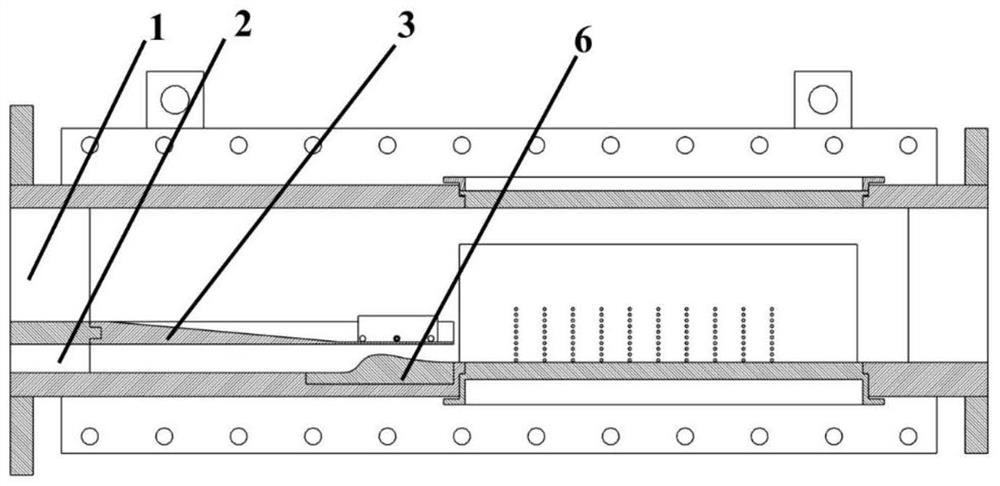

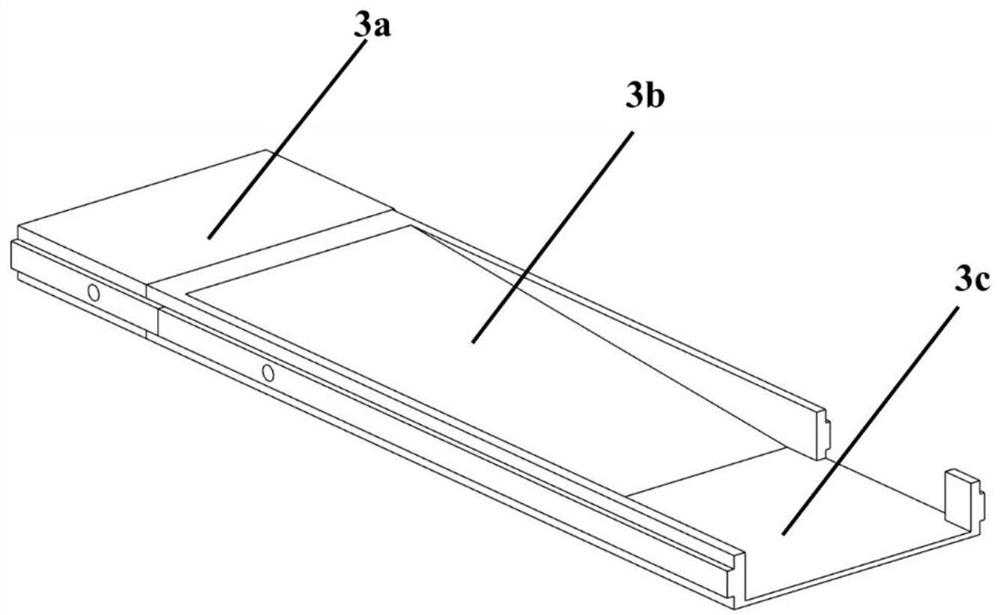

[0026] The present invention as Figure 1-5 As shown, it includes a mixing chamber main body 5, a subsonic flow channel 1, a supersonic flow channel 2, a support plate 3, a Laval nozzle 6, a direct injection fuel injection rod 8 and a cover plate 7;

[0027] There is a rectangular channel in the mixing chamber main body 5, the head port of the rectangular channel is connected to the air inlet channel through the welding flange 4, and the tail port of the rectangular channel is connected to the subsequent channel through the mixing chamber end flange 13; The rectangular channel includes a mixing chamber and an observation chamber that communicate with each other, and the mixing chamber is divided into a subsonic flow channel 1 in the upper layer and a superso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com