Bridge deck crack high-strength repairing method

A repair method and high-strength technology, which can be used in bridge repair, road repair, bridge, etc., can solve problems such as secondary cracks, concrete swelling, cracks, etc., and achieve the effect of avoiding secondary cracking and improving repair strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

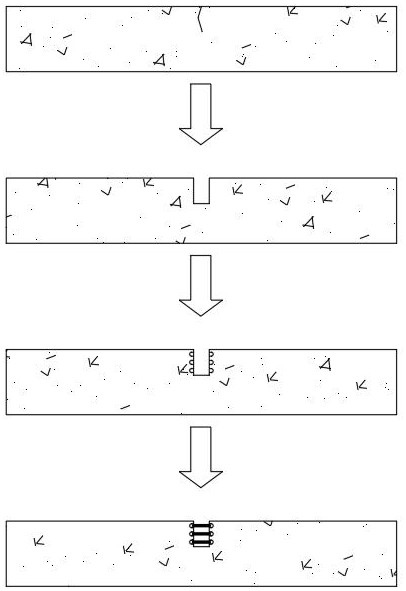

[0046] see figure 1 , a high-strength repair method for bridge deck cracks, comprising the following steps:

[0047] S1. Determine the size of the slot according to the size of the crack, and expand the slot through the slotting machine, and the width is not less than 1.5cm;

[0048] S2. Drill holes evenly on the inner wall of the crack, and then use a high-power blower or hot air gun to purge for 1-2 times, and then purge a small amount of debris and sundries in the groove. The special hook is manually cleaned, and then blown again after cleaning to ensure that the seam is absolutely dry and clean;

[0049] S3. Inject magnetic concrete into the hole, put an appropriate number of self-connectors into the crack after it is initially solidified, and realize the connection between two adjacent holes under the magnetic attraction of the magnetic concrete;

[0050] S4. The self-connector triggers the gap-making action in the hole, and injects repair concrete into the crack until ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com