A method for producing fuel oil from biomass

A biomass raw material and biomass technology, which is used in the preparation of liquid hydrocarbon mixtures, petroleum industry, processing of hydrocarbon oil, etc., can solve the problems of increasing the content, increasing the difficulty of product separation and purification, and low yield of liquid products, and achieves heating and absorption. rate increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] First weigh a certain amount of silica sol and add water to dilute to 5% aqueous sol solution, then add а-Al to the silica sol solution 2 o 3 Powder (diameter less than 1μm), ZrO 2 Powder (diameter less than 0.5 μm), then add appropriate amount of ethanol, put it into a ball mill for wet grinding. After wet milling for 24 hours, dry it. The powder passed through a 60-mesh sieve is calcined at 600°C for 2 hours, and then shaped as required. The molded body was sintered at 1200°C for 2 hours in the atmosphere, and then slowly cooled to room temperature with the furnace temperature. Two kinds of microwave additives TC-1 and TC-2 were prepared according to the different proportions of raw materials, and the composition of TC-1 was 65%Al 2 o 3 , 35%SiO2 2 , 5%ZrO 2 , TC-2 composition is 85% Al 2 o 3 , 10%SiO2 2 , 5%ZrO 2 .

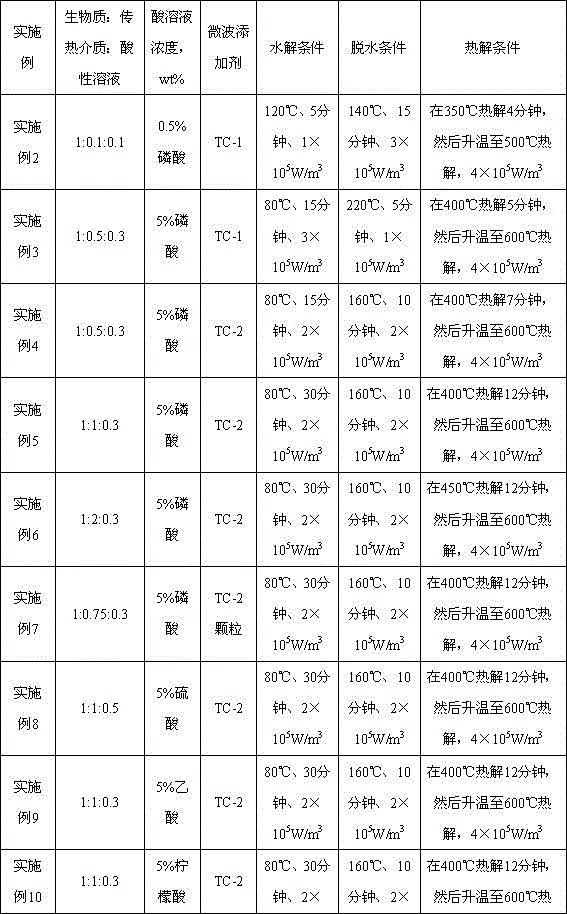

Embodiment 2~12

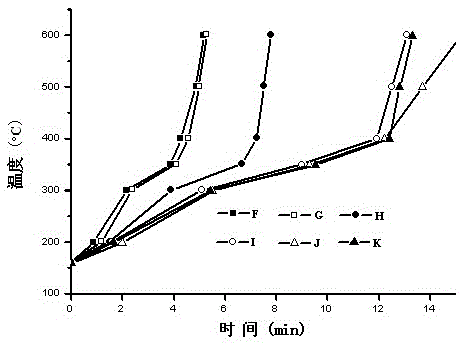

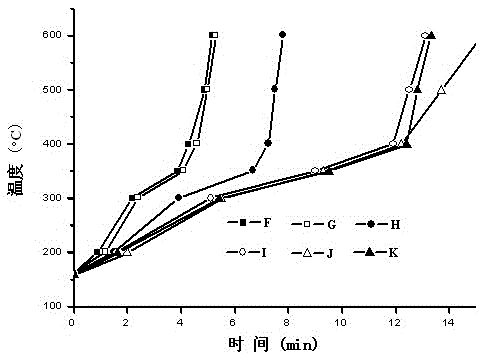

[0036] Mix forest residues (5mm), microwave additives and acidic solution according to a certain ratio and place them in a microwave pyrolysis reactor. Firstly, microwave hydrolysis treatment at 80~120°C for 5~30 minutes, and then heat up to 140~220°C for dehydration , the time is 5~15 minutes, the power density of the whole hydrolysis and dehydration process is 1×10 5 ~3×10 5 W / m 3 . Adjust power to 4×10 5 ~10×10 5 W / m 3 , and pyrolyze the above-mentioned dehydrated biomass at 350-450°C for 4-12 minutes, and then heat up to 500-600°C until no gas is generated. The generated pyrolysis volatiles are recovered by multi-stage condensation and Solid-liquid separation is carried out to obtain biofuel oil. The whole reaction process maintains a negative pressure state, and the reaction pressure is 0.01~0.1MPa. The specific reaction conditions are shown in Table 1, and the liquid composition distribution and yield are shown in Table 2 and Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com