Method, system and process for preparing powdered activated coke by carbonization and activation of pulverized coal

An activated coke, two-stage technology, used in coke ovens, petroleum industry, special forms of dry distillation, etc., can solve the problems of low calorific value of coke-making pyrolysis gas, high energy consumption of coke-making, and difficulty in utilization, etc. The effect of high content, low consumption of coking coal and high calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0044] The third embodiment of the present invention provides a two-stage process for preparing powdered activated coke by carbonizing and activating pulverized coal, providing the above system, including the following steps:

[0045] The pulverized coal is heated by two heat sources in the shell side of the reactor in the carbonization section, one comes from the waste heat flue gas from the heat exchange tube of the reactor in the activation section, and the waste heat flue gas is indirectly heated through the heat exchange tube, and the other comes from the heat exchange tube in the activation section. Activated gas, activated gas is mixed with coal powder for direct heating, coal powder and activated gas are heated in the carbonization section reactor to undergo pyrolysis carbonization reaction to obtain carbonized material and pyrolysis gas;

[0046] The pyrolysis gas is burned by the gas burner to produce combustion flue gas;

[0047] The carbonized material enters the s...

Embodiment 1

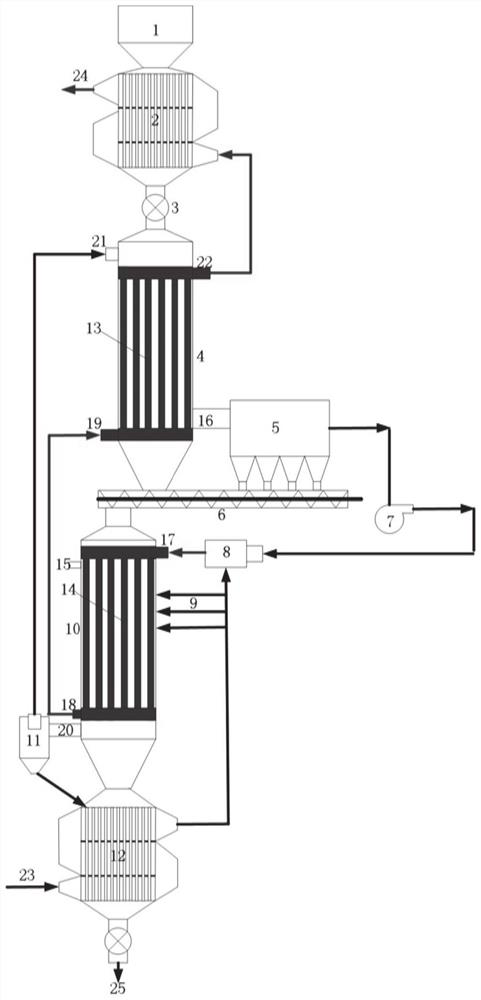

[0057] A two-stage system for preparing powdered activated coke by carbonizing and activating pulverized coal, such as figure 1 As shown, it includes pulverized coal preheater 2, carbonization section reactor 4, pyrolysis gas high temperature dust collector 5, carbonization material screw feeder 6, gas burner 8, activation section reactor 10, powder coke cooler 12, etc. The main components.

[0058] The pulverized coal bin 1 is at the top, the pulverized coal bin 1 is connected to the pulverized coal preheater 2, the outlet of the pulverized coal preheater 2 is connected to the gas lock feeder 3, and the gas lock feeder 3 is connected to the carbonization section reactor 4 inlet Connection, the carbonization material outlet at the bottom of the carbonization section reactor 4 is connected with the carbonization material screw feeder 6, and the carbonization pyrolysis gas outlet 16 is provided on the lower side of the carbonization section reactor 4, which is connected with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com