Functional degradable material with controllable degradation period and preparation method thereof

A technology for degrading materials and degradation cycles, applied in the field of functional degradable materials and their preparation, can solve the problems of difficult to control degradation time, deviation of material mechanical properties, and insufficient degradation, achieve good stiffness and mechanical properties, and improve friction. Condition, easy demoulding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

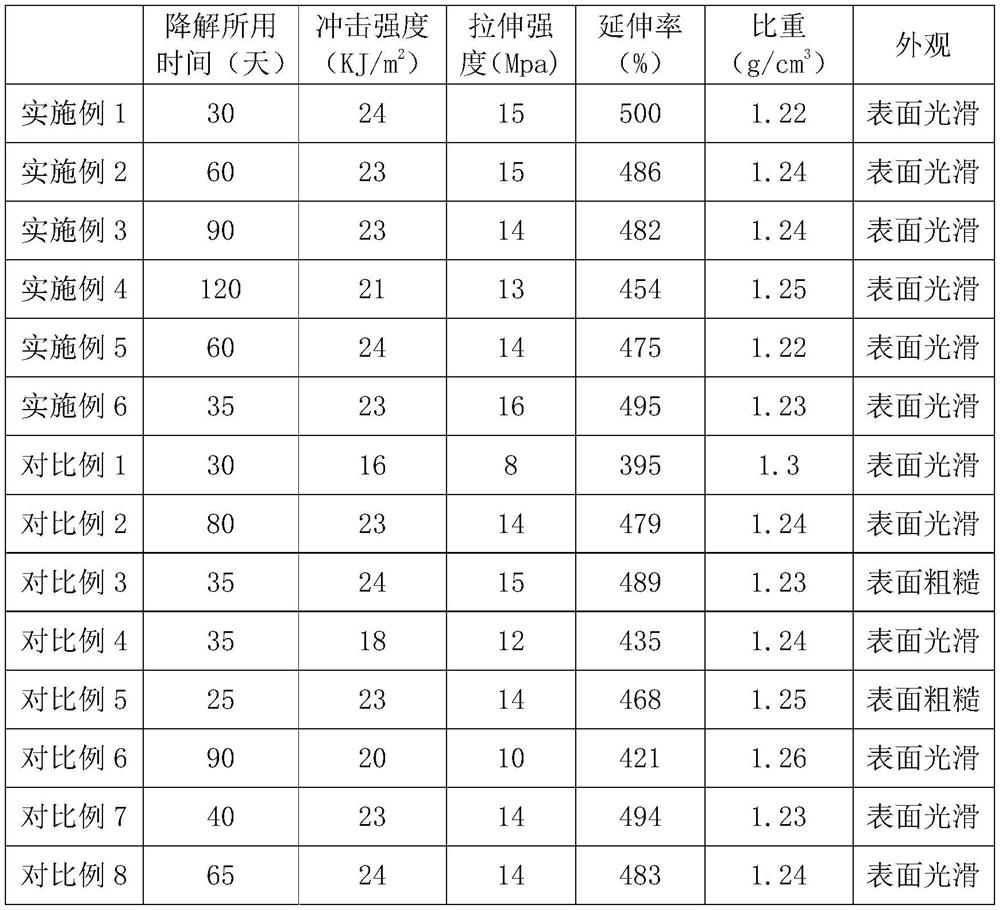

Examples

preparation example Construction

[0070] In one embodiment, the modified starch preparation method comprises the following steps:

[0071] (1) drying the starch at 80-110°C for 3-5h;

[0072] (2) Add the dried starch and maleic anhydride of step (1) into the reaction kettle by weighing the corresponding weight, and after reacting at 60-90°C for 0.5-3h, take out the reacted product;

[0073] (3) washing the reaction product obtained in step (2) with ethanol for 4-6 times, then suction filtering, and finally placing the filter cake in an oven, drying at 70-90° C. for 12-18 hours to obtain modified starch.

[0074] The modified starch weakens the hydrogen bond between the starch molecules, improves the thermoplasticity of the modified starch and can improve the hydrophobicity of the starch material to a certain extent, and the modified starch is more easily combined with the polymer in the system of the present invention. Combined, the amount of compatibilizer is reduced at the same time, so that the performance...

Embodiment 1

[0091] Embodiment 1 of the present invention specifically provides a functional degradable material with a controllable degradation period. The raw materials include, in parts by weight, 40 parts of polybutylene terephthalate, 6 parts of carbon dioxide copolymer, polybutylene 25 parts of butylene glycol ester, 4 parts of compatibilizer, 0.35 part of lubricant, 4 parts of plasticizer, and 0.2 part of antioxidant.

[0092] The raw material of the functional degradable material with a controllable degradation period also includes a mixture of modified starch, polyglycolic acid and polydioxanone.

[0093] The weight ratio of the modified starch to polybutylene succinate is 0.8:1.

[0094] The addition amount of the mixture of polyglycolic acid and polydioxanone is 4% of the total weight of the raw materials of the functional degradable material with a controllable degradation cycle.

[0095] The weight ratio of polyglycolic acid to polydioxanone is 12:2.

[0096] The polybutylen...

Embodiment 2

[0121] Embodiment 2 of the present invention specifically provides a functional degradable material with a controllable degradation period. The weight ratio of polybutylene succinate is 0.7:1, and the weight ratio of polyglycolic acid and polydioxanone is 10:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com