Building mortar taking gold ore tailings as full aggregate and preparation method thereof

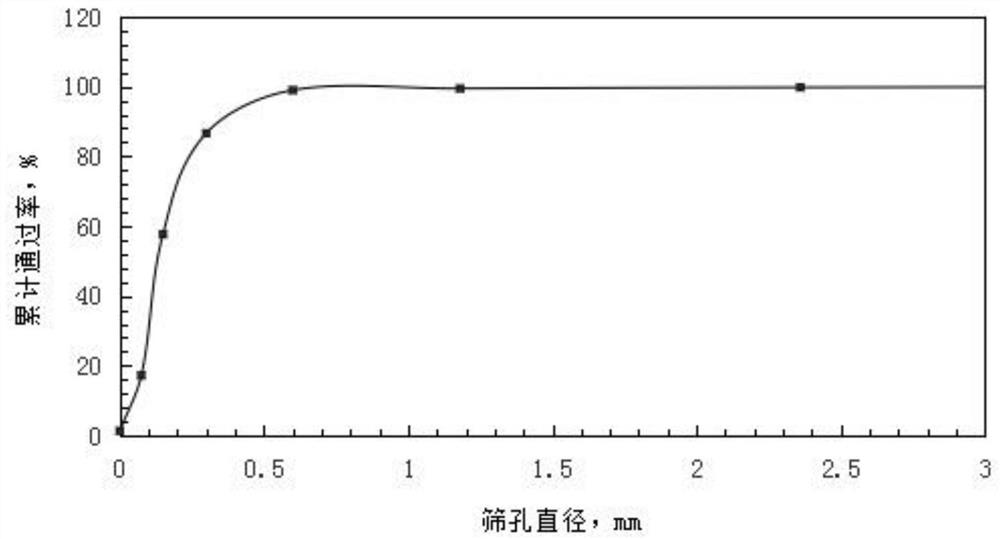

A technology of gold mine tailings and mortar, which is applied in the field of building materials, can solve the problems of reduced strength, small tailings particle size, and increased shrinkage of mortar, and achieve the effects of improved shrinkage and strength, reduced production costs, and reduced mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

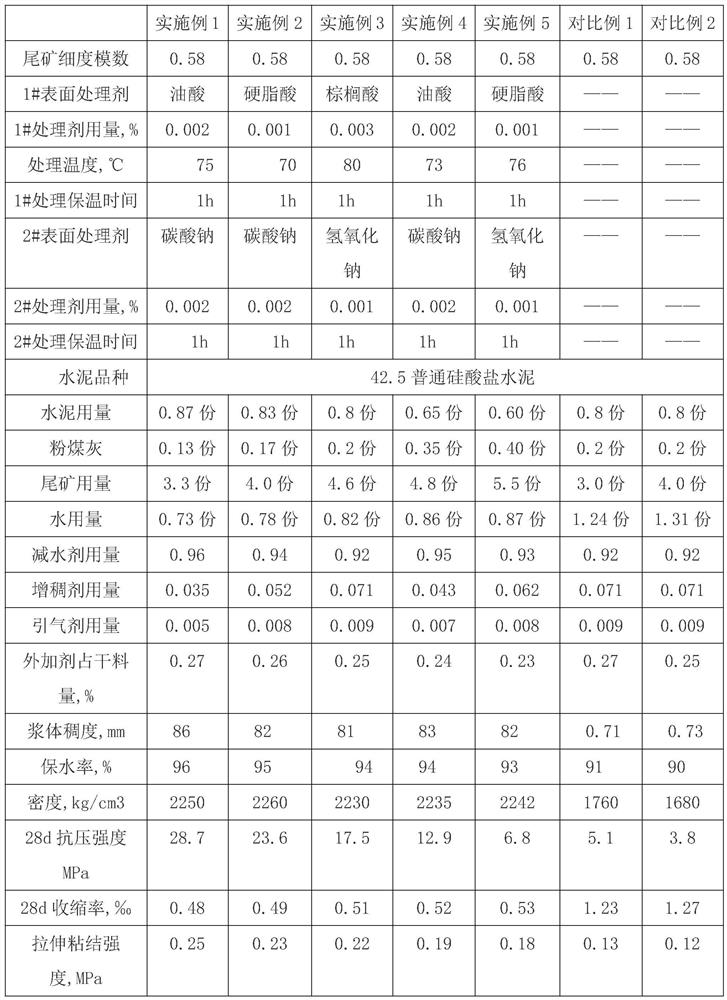

[0051] The present invention also relates to a method for preparing the construction mortar with gold mine tailings as the total aggregate. The method includes the following steps: the materials and their dosage are shown in Table 1.

[0052] Step 1: First, sieve the tailings to remove the mud, then mix and heat evenly with 1# surface treatment agent at 70-80°C and keep it for 1 hour, then add 2# surface treatment agent and continue mixing and heating for 1 hour to obtain the surface treated tailings;

[0053] Step 2: Mix and stir the polycarboxylate high-efficiency water reducer, thickener and air-entraining agent to completely dissolve the solid particles to obtain a composite admixture.

[0054]Step 3: Mix the mortar mixing water and the composite admixture liquid evenly to obtain an aqueous admixture solution;

[0055] Step 4: Mix the cementitious material and the tailings treated on the surface evenly in a forced mixer to obtain dry tailings mortar;

[0056] Step 5: Add...

Embodiment 2

[0058] The present invention also relates to a method for preparing the construction mortar with gold mine tailings as the total aggregate. The method includes the following steps: the materials and their dosage are shown in Table 1.

[0059] Step 1: First, sieve the tailings to remove the mud, then mix and heat evenly with 1# surface treatment agent at 70-80°C and keep it for 1 hour, then add 2# surface treatment agent and continue mixing and heating for 1 hour to obtain the surface treated tailings;

[0060] Step 2: Mix and stir the polycarboxylate high-efficiency water reducer, thickener and air-entraining agent to completely dissolve the solid particles to obtain a composite admixture.

[0061] Step 3: Mix the mortar mixing water and the composite admixture liquid evenly to obtain an aqueous admixture solution;

[0062] Step 4: Mix the cementitious material and the tailings treated on the surface evenly in a forced mixer to obtain dry tailings mortar;

[0063] Step 5: Ad...

Embodiment 3

[0065] The present invention also relates to a method for preparing the construction mortar with gold mine tailings as the total aggregate. The method includes the following steps: the materials and their dosage are shown in Table 1.

[0066] Step 1: First, sieve the tailings to remove the mud, then mix and heat evenly with 1# surface treatment agent at 70-80°C and keep it for 1 hour, then add 2# surface treatment agent and continue mixing and heating for 1 hour to obtain the surface treated tailings;

[0067] Step 2: Mix and stir the polycarboxylate high-efficiency water reducer, thickener and air-entraining agent to completely dissolve the solid particles to obtain a composite admixture.

[0068] Step 3: Mix the mortar mixing water and the composite admixture liquid evenly to obtain an aqueous admixture solution;

[0069] Step 4: Mix the cementitious material and the tailings treated on the surface evenly in a forced mixer to obtain dry tailings mortar;

[0070] Step 5: Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com