Improved cutting fluid recovery device in field of machining

A technology of mechanical processing and recycling devices, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of high labor intensity and many steps of manual participation, and achieve cost reduction, simplification of operation steps, and cleaning efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

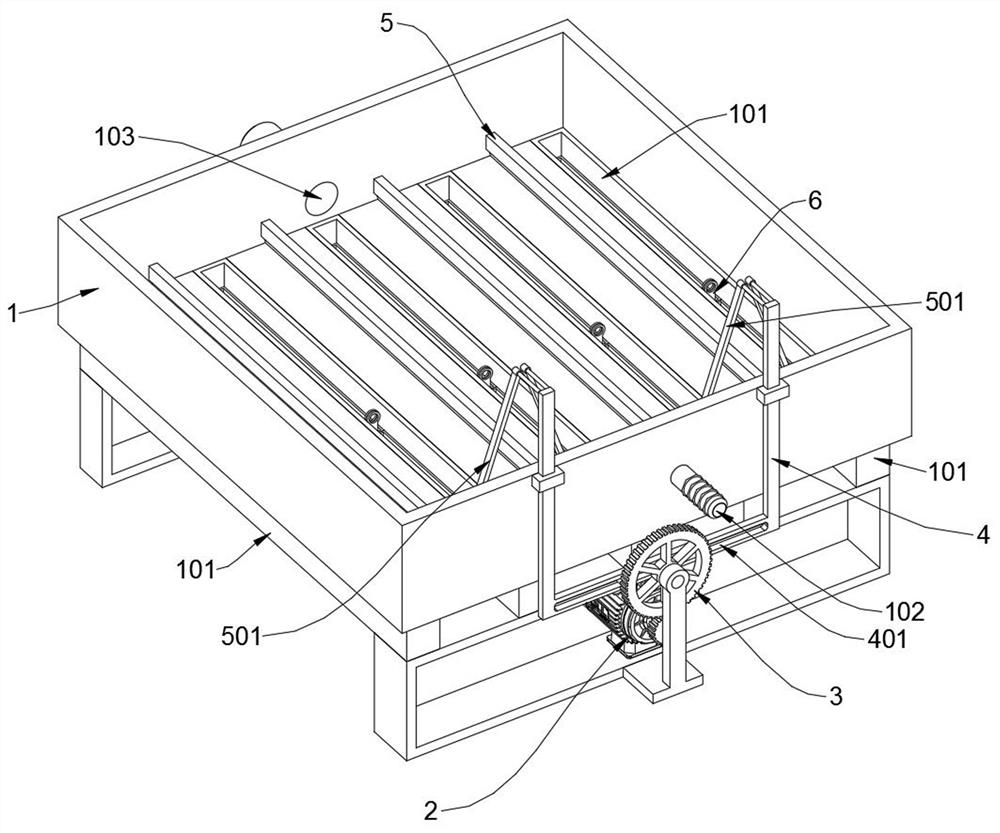

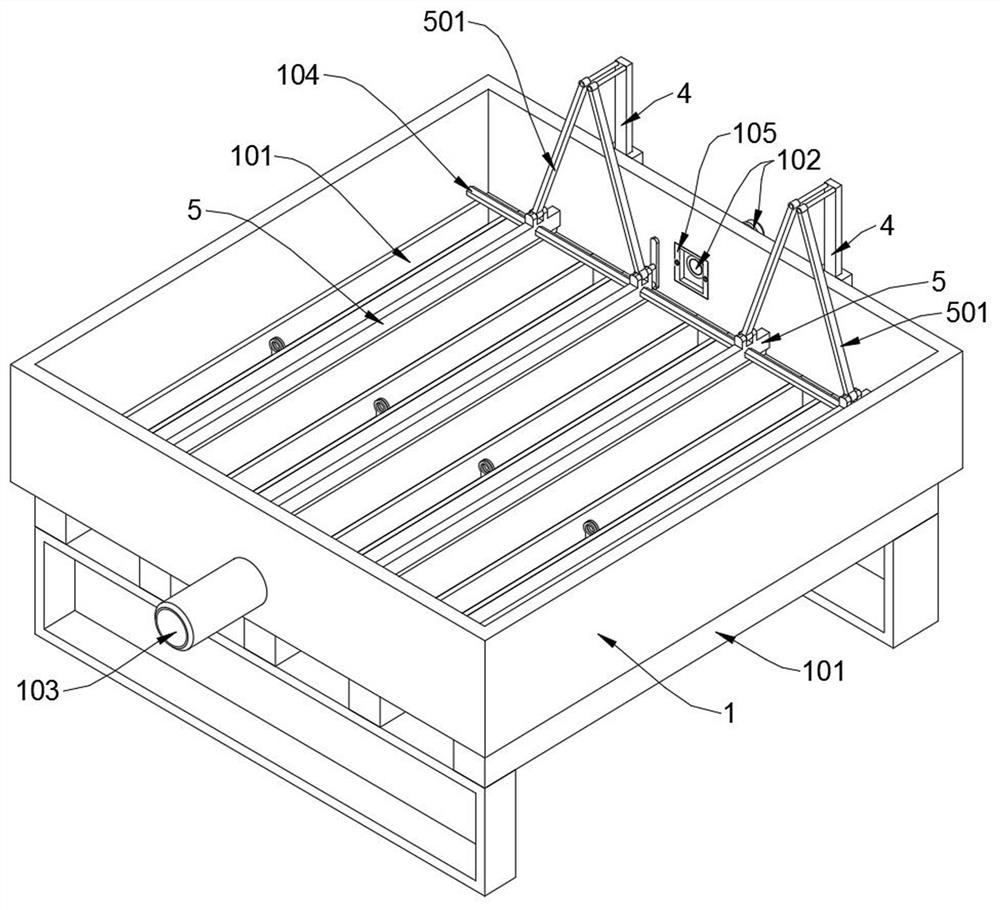

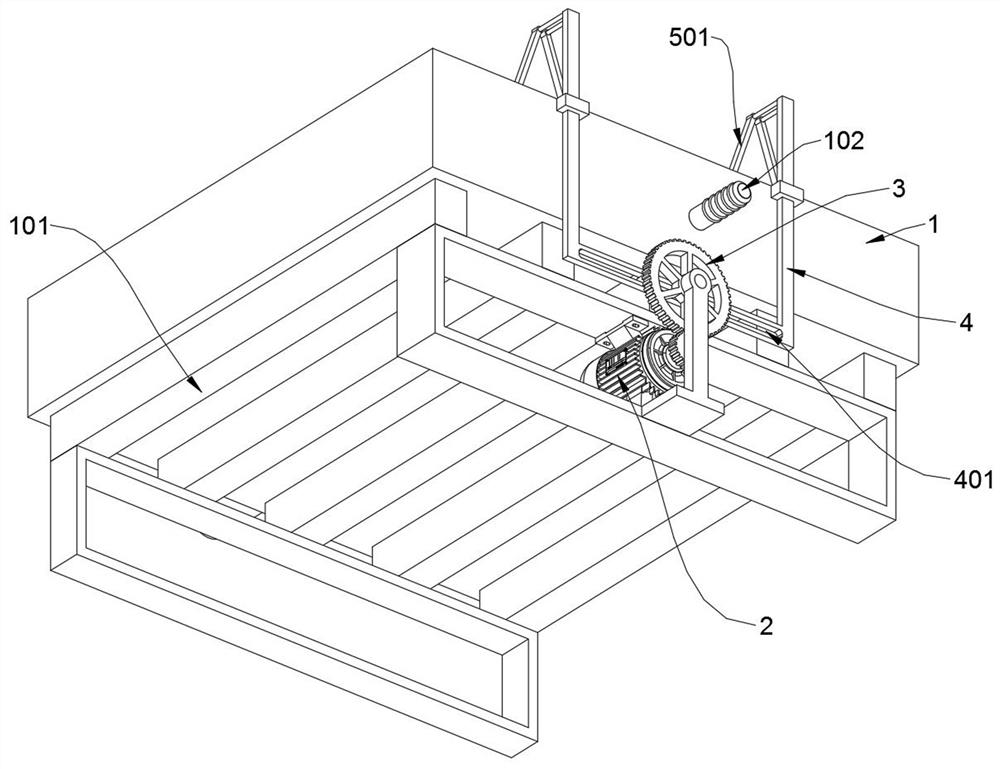

[0030] see Figure 1 to Figure 8 , an embodiment provided by the present invention: an improved cutting fluid recovery device in the field of mechanical processing, including a liquid storage tank 1, the liquid storage tank 1 includes a long slag storage tank 101, a liquid suction pipe 102, a liquid inlet pipe 103, a hexagonal prism shaft 104 and a square filter screen 105. The liquid storage tank 1 has a square structure as a whole, and a row of five long slag storage tanks 101 protruding downwards from its bottom plate, the five long slag storage tanks 101 Two filter boxes 6 are spliced and installed in the tank 101, and the bottom opening of the filter box 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com