Part cleaning device for intelligent robot machining

An intelligent robot and cleaning device technology, which is applied to the cleaning method using liquid, the cleaning method using tools, and the cleaning method using gas flow, etc. Small damage and improved cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

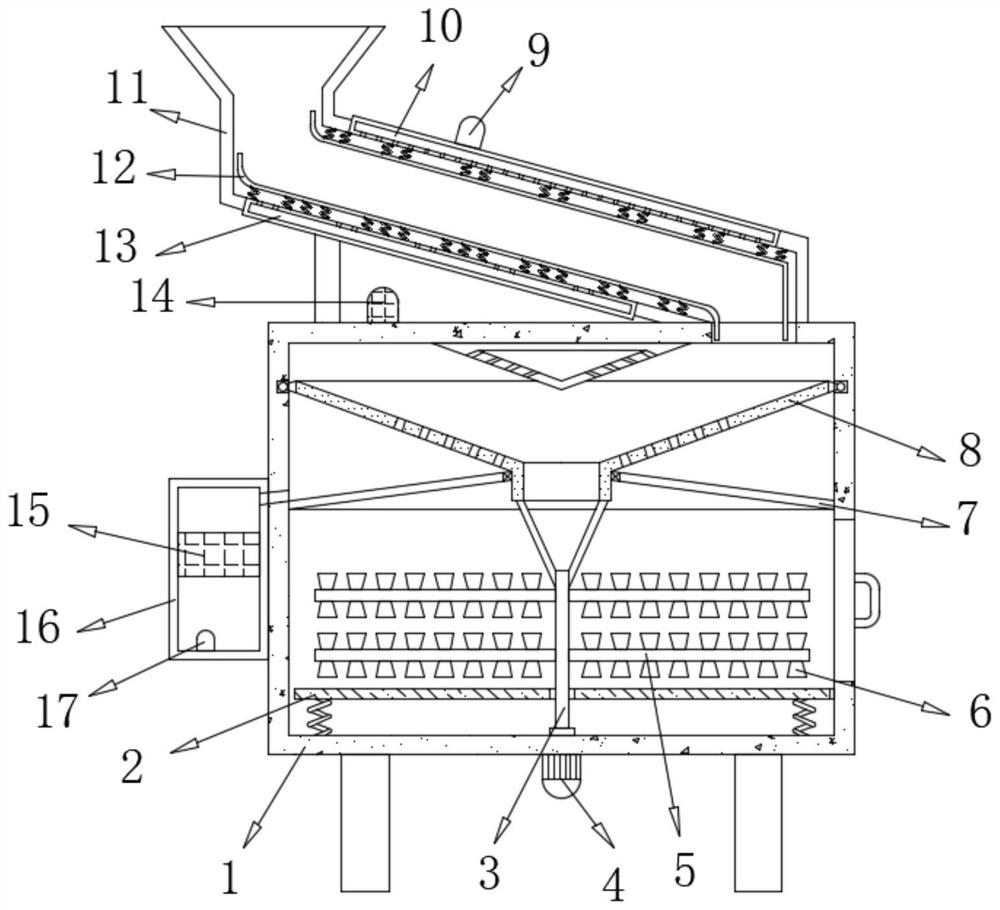

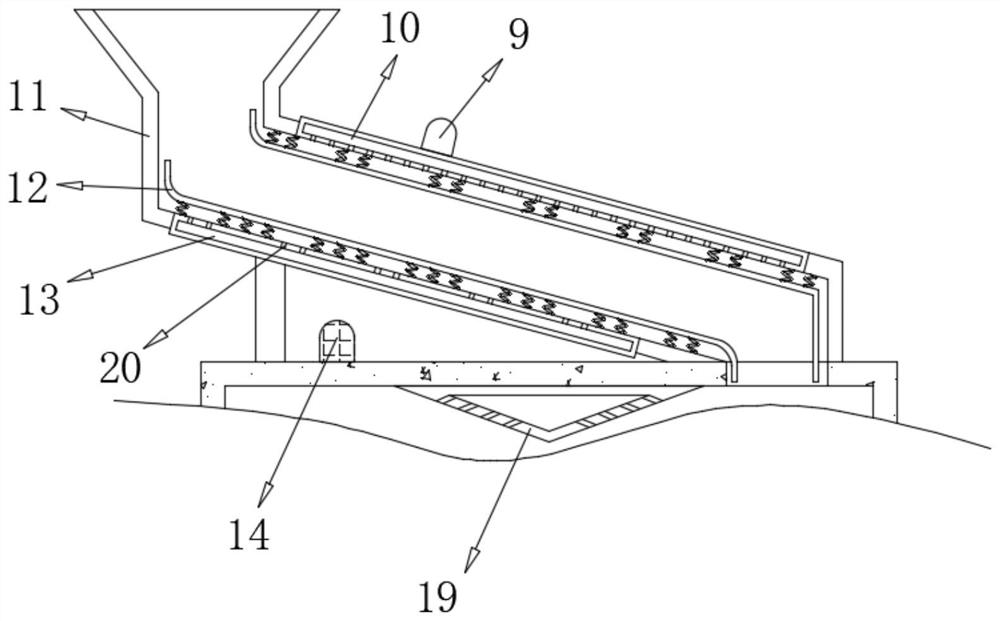

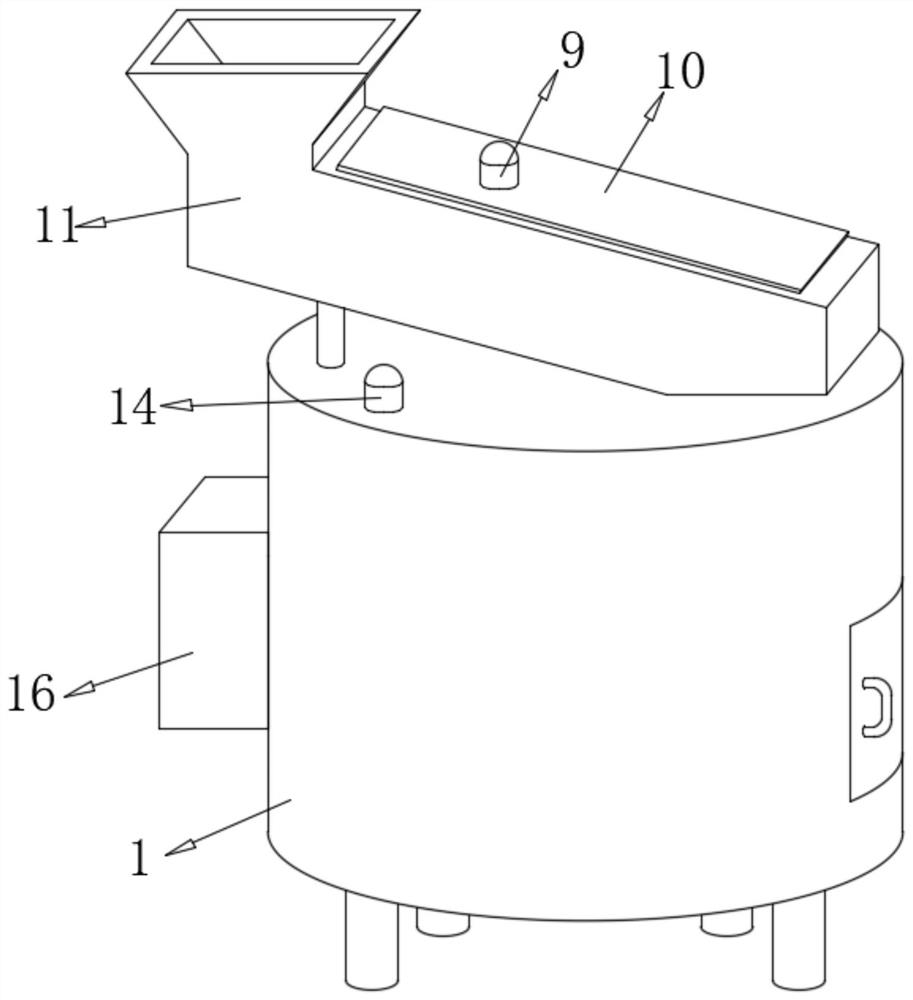

[0025] refer to Figure 1-3 , a parts cleaning device for intelligent robot processing, comprising a box body 1, the top outer wall of the box body 1 is connected with an inclined feeding shell 11 by fastening bolts, and the bottom inner wall of the feeding shell 11 is fastened Bolts are connected with an air outlet plate 13, the top outer wall of the air outlet plate 13 is connected with the first mesh plate 12 by a spring, and the top outer wall of the air outlet plate 13 is provided with first air outlet holes 20 arranged at intervals, and the top inner wall of the feeding shell 11 passes through The fastening bolts are connected with a dust suction plate 10, and the bottom outer wall of the dust suction plate 10 is connected with a second mesh plate through a spring. The bottom outer wall of the dust suction plate 10 is provided with evenly distributed dust suction holes, and the top of the dust suction plate 10 The outer wall is connected with the vacuum cleaner 9 by fast...

Embodiment 2

[0035] refer to Figure 4 , a parts cleaning device for intelligent robot processing. Compared with Embodiment 1, the bottom of both sides of the rotating shaft 3 is connected with an air outlet pipe 18 by fastening bolts, and the top outer wall of the air outlet pipe 18 is provided with evenly distributed The second air outlet hole, the air outlet pipe 18 is located at the bottom of the buffer net plate 2.

[0036] Working principle: when the silicone rod 5 stirs and cleans the parts, the air pump 14 and the air outlet pipe 18 blow air inside the box 1, thereby driving the water in the parts and the box 1 to turn, and improving the cleaning efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com