Adjusting method of coating mechanism

An adjustment method and coating technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of different amount of material on the pick-up roller, influence on product quality, tilting of the paint plate, etc., and achieve uniform amount of material on the surface, Ensure stability and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for adjusting a paint mechanism, comprising the steps of:

[0043] Step 1: Drive the drive locking part on the coating mechanism;

[0044] Step 2: The driving part drives the lifting part to move left and right through the connecting part;

[0045] Step 3: The lifting part drives the paint tray 1 and the paint tray frame 2 on the paint mechanism to realize the lifting action;

[0046] Step 4: When the paint tray 1 reaches the working position, drive the locking part to lock.

[0047] In actual use, the adjustment of the paint mechanism is completed through four steps, ensuring the stability of the paint mechanism during the lifting process, avoiding the paint of the paint pan from splashing out of the paint pan, and the paint pan does not tilt, and the pick-up roller is stained. The uniform amount of material ensures the quality of the product. The structure of the invention is simple and easy to implement.

Embodiment 2

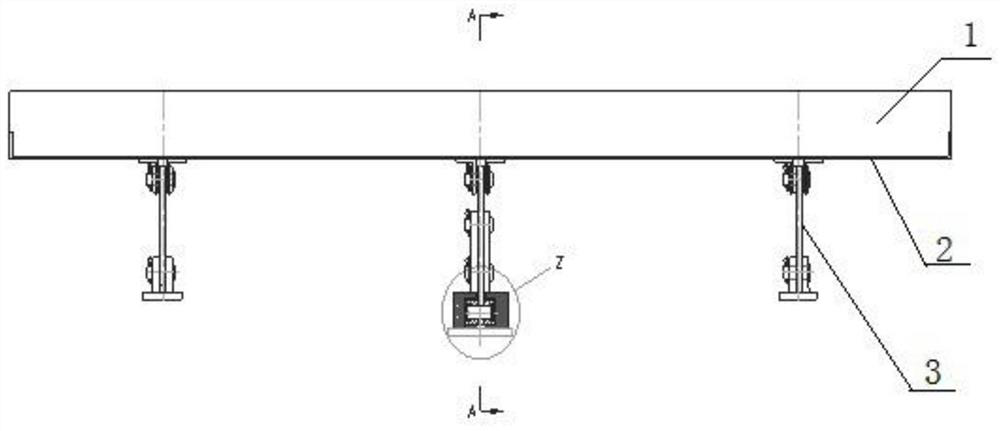

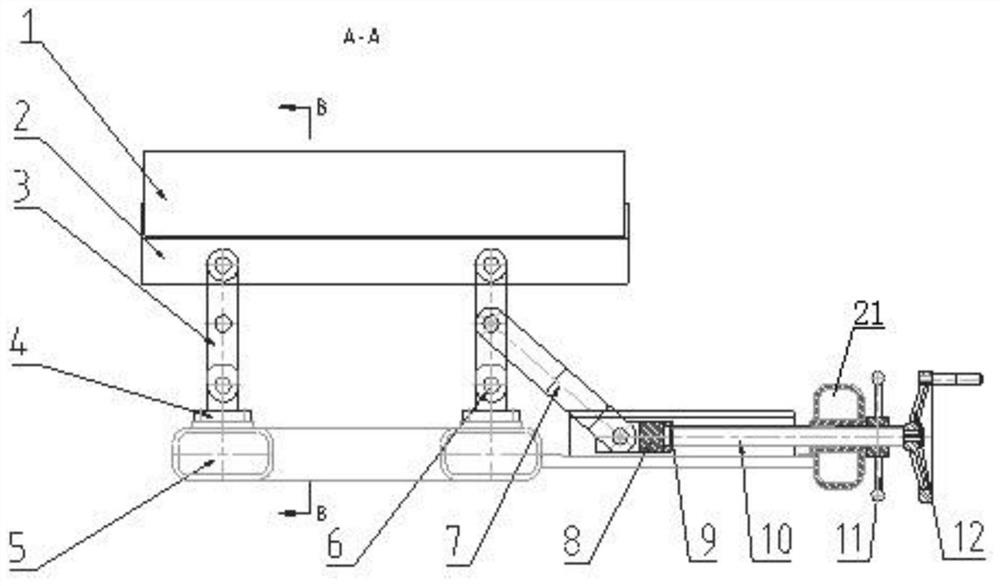

[0049] refer to figure 1 with figure 2 The adjustment method of a paint mechanism shown includes a paint tray 1, a paint tray frame 2, a lifting part, a support 4, a frame 5, a pin shaft 6, a connecting part and a drive locking part; , paint pan frame 2, lifting part, support 4 and frame 5 are arranged sequentially from top to bottom, the material pan 1 is placed in the paint pan frame 2, and the upper and lower ends of the lifting part are connected with the paint pan frame 2 and the support 4 respectively. The pin connection is through the pin shaft 6; the support 4 is connected to the frame 5; the two ends of the connection part are pin connected with the lifting part and the driving locking part through the pin shaft 6 respectively.

[0050]In actual use, the driving locking part is pinned to the lifting part through the connecting part to realize the lifting action of the paint tray rack and the paint tray. When the paint tray reaches the working position, it is locked ...

Embodiment 3

[0053] refer to figure 1 The adjustment method of the paint mechanism shown is based on the first embodiment: the middle part of the paint tray 2 is a horizontal plate structure, and the paint tray 2 is surrounded by raised baffles.

[0054] In actual use, the paint tray 2 adopts the technical solution, so that the paint tray 1 can be placed on it stably, ensuring that the pick-up roller can be evenly stained, thereby ensuring the quality of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com